Smart Control System: One-touch start, flexible modes, remote IoT monitoring

High Precision Mixing: ±0.5% aggregate accuracy, full-process automation

Heavy-Duty Performance: Durable design, predictive maintenance, highway-ready

Asphalt mixing plant is a machine used to produce hot mix asphalt by combining aggregates, bitumen, and filler in precise ratios. In Indonesia’s fast-growing road industry, it ensures stable quality, fast output, and strong pavement. We offer reliable, cost-effective types of asphalt plants built for local needs and tough tropical conditions.

Our Asphalt Manufacturing Plants Are Working All Over Indonesia

From Java’s busy highways to remote village roads in Sulawesi, our asphalt mixing plants are already in action. Our asphalt mixing machines are helping local contractors build faster, stronger roads—whether it’s for government toll projects, airport upgrades, or rural access improvement. Indonesian builders trust us because it works—rain or shine, city or island.

What are the Types of Asphalt Plants in Indonesia?

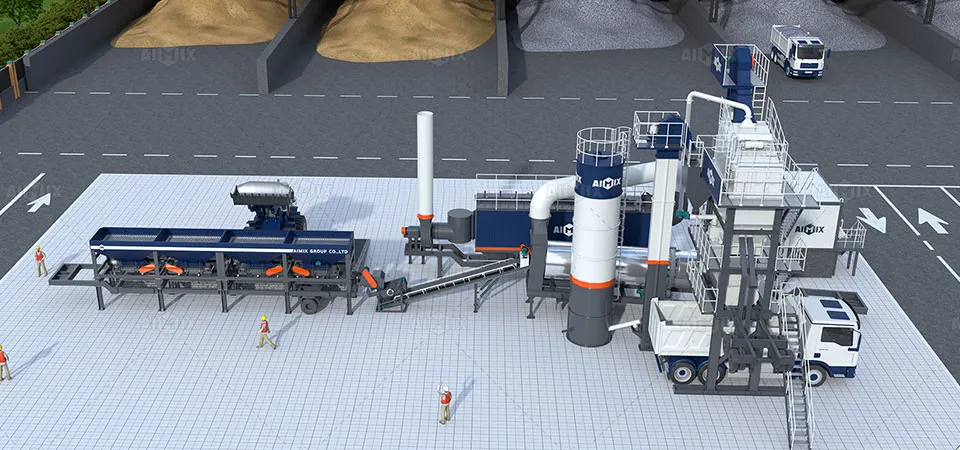

Looking for the right asphalt mixing plant terdekat in Indonesia? There are 4 main jenis jenis asphalt mixing plants: stationary batch type (ALQ), mobile batch type (ALYQ), stationary drum type (ALT), and mobile drum type (ALYT). Each type of amp hotmix fits different project needs—from big highway jobs to flexible rural repairs. Let’s learn about the types and spesifikasi asphalt mixing plant.

ALQ Series – Stationary Batch Type Asphalt Plant (Fixed, Forced Mixing)

- Hot Selling Models: ALQ-80, ALQ-100

- Capacity: 40-400TPH

- Cycle Time: 45s

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

- Best for: Large-scale, long-term projects (e.g. highways, airports)

Stationary Asphalt Batch Plant Features

- Stable Production: Permanent setup for consistent, continuous output.

- High Precision: Aggregate weighing accuracy ±0.5%, bitumen ±0.25%.

- Smart Control: One-click start automates 50+ manual tasks, saving time.

- Remote Monitoring: IoT for real-time alerts and maintenance reminders.

- Heavy-Duty Design: Wear-resistant parts last over 1 million tons of output.

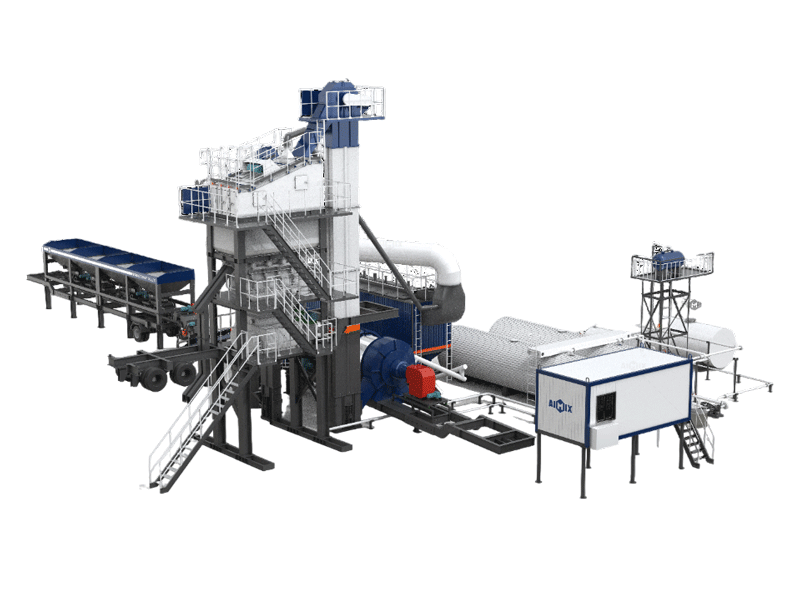

ALYQ Series – Mobile Batch Type Plant Asphalt (Mobile, Forced Mixing)

- Hot Selling Models: ALYQ-60, ALYQ-80, ALYQ-100

- Capacity: 40-160TPH

- Cycle Time: 45s

- Asphalt Temperature: 120-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

- Best for: Multi-site contractors, short-term toll road works

Mobile Asphalt Mixing Plant Features

- Fast Relocation: Quick setup and production start within 24 hours.

- AI Smart Operation: Auto recipe change and mobile app monitoring.

- Efficient Mixing: “Volcanic boiling” mixer boosts output by 10 tons/hour.

- Accurate Metering: 1% error reduces material waste by 80 tons/day.

- Low Manpower Needs: Operated by just 2 staff, cutting labor in half.

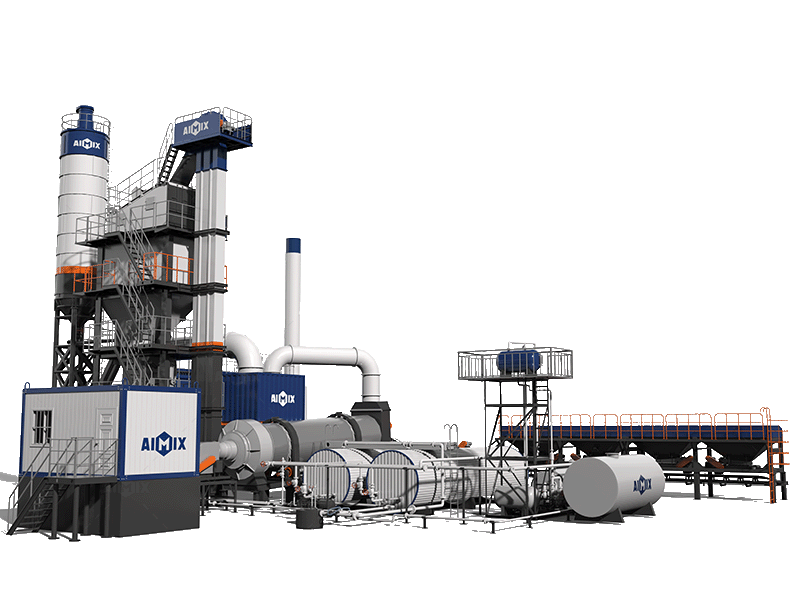

ALT Series – Stationary Drum Type Asphalt Plant (Fixed, Continuous Mixing)

- Hot Selling Models: ALT40, ALT100, ALT120

- Capacity: 20-120TPH

- Fuel Consumption: 13-15kg/t

- Asphalt Temperature: 120-180 ℃

- Dust filter: Bag dust filter

- Best for: Flat terrain, centralized rural road network projects

Stationary Asphalt Drum Mix Plant Features

- Simple Structure: Efficient tower with optimized drum drying.

- Cost-Effective: Low investment cost for smaller budgets/long-term use.

- Smart Heat Control: Built-in temperature management for even mixing.

- Fixed Setup: Takes about a month to install, ideal for stable sites.

- Easy Maintenance: Fewer moving parts, reduced servicing and downtime.

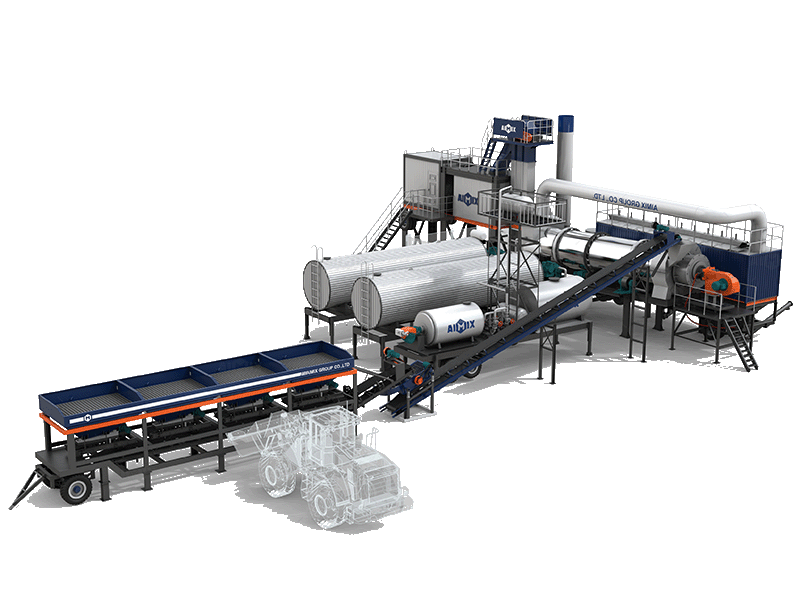

ALYT Series – Mobile Drum Mesin Amp Aspal (Mobile, Continuous Mixing)

- Hot Selling Models: ALYT40, ALYT80, ALYT100

- Capacity: 20-120TPH

- Asphalt Temperature: 120-180 ℃

- Dust filter: Bag/Water dust filter

- Fuel Consumption: 5-7.5kg/t(Fueling Oil)/13-15kg/t(Burning Coal)

- Best for: Rural roads, repairs, short-term projects in remote areas

Mobile Asphalt Drum Mix Plant Features

- Modular Design: Low center of gravity for easier transportation.

- Terrain-Friendly: Handles hilly, remote sites with ease.

- Fast Transfer: Ready to relocate in 3–5 days for mobile teams.

- Low Maintenance: Simple design, minimal repairs needed.

- Space-Saving: Smaller footprint and easier storage for limited sites.

How to Choose the Right Asphalt Plant for Your Project in Indonesia

Different roads need different asphalt mixer plants. Village roads? City upgrades? Big highway jobs? Don’t waste time or money on the wrong type. Check the table below to quickly find the best-fit plant for your project — easy, smart, and practical for real construction needs in Indonesia.

| Customer Scenario | Key Points You Often Meet | Recommended Solutions | Why This is the Best Choice | Location Considerations |

|---|---|---|---|---|

| Small-Scale Road Repairs | Limited budget, need for mobility, fast setup | ALB Series Portable Asphalt Mixer ALYT Series Mobile Asphalt Drum Mix Plant | ALB Series: Compact, low-cost, fast setup. For small repairs. ALYT Series: Mobile, quick install. For small to mid projects. | Sumatra, Kalimantan—ideal for small-scale repairs where mobility and fast deployment are key. |

| Highway Construction (Large-Scale) | High capacity, high-quality asphalt needed | ALQ Series Stationary Asphalt Batch Mixing Plant | ALQ Series provides precision, high capacity, and consistent output, making it perfect for large-scale projects like highways. | Java, Bali—large-scale highway projects needing high-quality asphalt for major roads and infrastructure. |

| Multiple Locations, Frequent Relocation | Need for flexibility, fast transitions, high productivity | ALYQ Series Mobile Asphalt Batch Plant ALYT Series Mobile Asphalt Drum Mix Plant | ALYQ Series and ALYT Series offer modular design, quick transitions, and flexibility for multiple sites and temporary setups. | Sulawesi, Papua—projects with frequent relocations, especially in remote areas. |

| Urban Roadwork (Limited Space & Environmental Concerns) | Space constraints, environmental compliance needed | ALYQ Series Mobile Asphalt Batch Plant ALYT Series Mobile Asphalt Drum Mix Plant | Both are highly mobile, designed for tight spaces with quick setup, and feature environmental compliance (e.g., dust control). | Jakarta, Surabaya—urban roadworks requiring quick setup, environmental concerns, and space efficiency. |

| Rural or Municipal Roadworks | Need for reliability, consistent output at a reasonable cost | ALB Series Portable Asphalt Mixer ALYT Series Mobile Asphalt Drum Mix Plant | ALB Series is cost-effective and ideal for small to medium projects. ALYT Series offers consistent output with greater mobility. | West Java, Sumatra—suitable for municipal and rural roads, where cost efficiency and flexibility are crucial. |

| Roadworks in Remote or Difficult Terrain | Challenging terrain, need for mobility and flexibility | ALB Series Portable Asphalt Mixer ALYT Series Mobile Asphalt Drum Mix Plant | ALB Series is compact and portable, perfect for remote areas. ALYT Series offers continuous production for rugged terrains. | Papua, East Kalimantan—suitable for remote areas where mobility and rugged terrain adaptation are essential. |

| High-Volume, Ongoing Asphalt Production | Continuous production, high yield, precision required | ALQ Series Stationary Asphalt Batch Mixing Plant ALT Series Asphalt Drum Mix Plant | ALQ Series offers high output and precision for large-scale, long-term projects. ALT Series offers low maintenance costs for ongoing asphalt production. | Bali, Central Java—ideal for long-term roadworks and high-output production on large-scale infrastructure projects. |

Need a custom solution? We’re here to help. Just tell us about your project — location, scale, road type — and we’ll offer a free tailored asphalt plant recommendation that fits your exact needs. 👉 Contact us now for expert support!

How Much Does an Asphalt Plant Cost in Indonesia?

When planning road projects in Indonesia, understanding the asphalt plant price is key to managing your budget well. Asphalt mix plant prices can vary based on your specific needs and plant configurations. Our asphalt mixing plant price ranges from $20,000 to $800,000. Don’t wait! Contact us now to get a personalized quote about the harga asphalt mixing plant baru.

Beyond Price: Key Costs to Consider for Asphalt Plants in Indonesia

When budgeting for an asphalt mixing plant amp in Indonesia, the upfront asphalt mixing plant harga (typically between $20,000 to $800,000) is just the start. To get the best value, consider these key cost drivers:

Transportation and Logistics

Shipping to remote islands like Papua or Sulawesi can add 5%–15% of the asphalt mixer plant cost due to complex routes and extra handling.

Installation and Setup

Site preparation and foundation work may cost 10%–20% of your total budget, especially in uneven or difficult terrain common in many Indonesian regions.

Fuel and Energy Costs

Diesel fuel prices in Indonesia average around $0.80–$1.20 per liter. A plant consuming 5–10 liters per batch could spend $200–$500 monthly, depending on production volume.

Maintenance and Spare Parts

Annual maintenance can reach 3%–5% of the plant’s purchasing harga aspal mixing plant. Choosing models with widely local parts reduces downtime and extra shipping costs.

Environmental Compliance

Installing dust collectors or emission controls can add 5%–10% upfront but saves fines and supports smoother approvals, especially near urban areas like Jakarta or Surabaya.

Project Scale and Flexibility

Mobile asphalt plants can reduce relocation costs by 30%–50% compared to fixed plants, ideal for scattered or short-term projects across Indonesia’s diverse islands.

Factoring in these real costs helps you budget smartly and avoid surprises, making sure your asphalt mixer plant suits your project and Indonesia’s unique challenges.

Popular Asphalt Plant Models Loved by Indonesian and Global Clients

Looking for a reliable jual aspal mixing plant Indonesia for your road projects? We offer several best-selling asphalt plant models that are widely used in village paving, city road upgrades, and government infrastructure projects. Let’s take a quick look at the favorites among Indonesian buyers.

ALQ-80 Stationary Batch Type

- Capacity: 80TPH

- Fuel consumption: 120-600kg/h

- Vibrating Screen(Layer): 4 layers

- Asphalt Temperature: 140-180 ℃

- Total Power: 300kw

- Dust Filter: Gravity, Cyclone, Bag, Water dust filter

ALYQ-80 Mobile Batch Type

- Capacity: 80TPH

- Fuel consumption: 120-600kg/h

- Vibrating Screen(Layer): 4 layers

- Asphalt Temperature: 140-180 ℃

- Mixing Cycle: 45s

- Dust Filter: Gravity, Cyclone, Bag, Water dust filter

ALYT-80 Mobile Drum Mix Plant

- Capacity: 80TPH

- Cold Aggregate Bin: 6.5m³×4

- Asphalt Temperature: 120-180 ℃

- Total Power: 135kw

- Dust Filter: Bag or Water dust filter

- Fuel Consumption: 5-7.5kg/t(Fuel Oil), 13-15kg/t(Burning Coal)

ALB-10 Mobile Asphalt Mixer

- Capacity: 8-12TPH

- Production Time: 10-15 min/batch

- Asphalt Temperature: 160-210℃

- Power Output: 30kw

- Dust Filter: Water dust filter

- Fuel Consumption: 5-6L Per Batch(Diesel)

Advanced Technologies & Patents Power Your Road Projects

Choosing the right aspal amp isn’t just about capacity—technology matters. Whether you’re paving highways in Java or maintaining hillside roads in Sulawesi, our asphalt mixing plants are designed with smart innovations to boost efficiency, quality, and ease of use in Indonesian conditions.

Smart Control Systems for Hassle-Free Operation

- One-Touch Start/Stop: Simplifies 50+ operations into a single button.

- Multi-Mode Interface: PC, touchscreen, and manual panel—adaptable for any operator.

- Remote Monitoring via IoT: Real-time status updates, maintenance reminders, fault alerts—track everything from your office or phone.

Intelligent Automation for Precise Production

- Automated Batching & Mixing: From aggregate to discharge—all automated.

- AI-Based Accurate Weighing: ±0.25% asphalt precision, reduces material waste and improves mix quality.

- Auto Calibration & E-Inspection: Easy to maintain, efficient in long-term operations.

Efficiency Boost with Modular & Mobile Design (Especially Mobile Type)

- Magnetic Modular Assembly: Fast plug-and-play setup with quick-connect water, gas & electricity—ready in 24 hours.

- No Foundation Required: Ideal for frequent site moves across islands.

- Flexible Mobile Drum Mix Patent: Certified design allows efficient mixing in tight or remote locations.

Heavy-Duty Components for Long-Term Durability

- 5-Year Wear-Resistant Parts: Blades, liners, and mixers last up to 5 years without replacement.

- Larger Cold Aggregate Hoppers: 20% bigger to reduce refilling time and improve continuity.

- Extendable Dust Pipes: ±3cm installation tolerance—faster, easier, and more adaptable to different terrains.

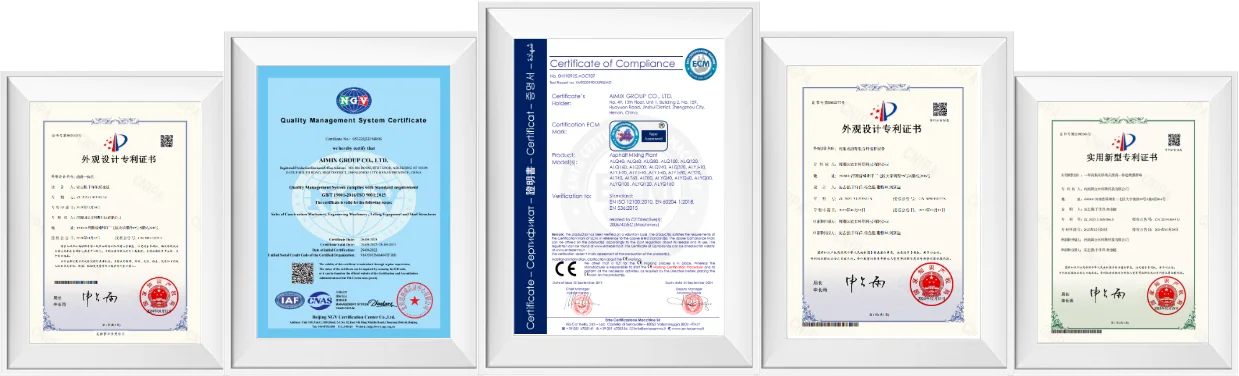

Certified & Patented Technologies

- Utility Model Patent – For high-mobility mobile drum mixing units.

- Pipeline Expansion Patent – For flexible, scalable installation in varied project sites.

- High-Integration Mixing Patent – For compact, high-precision asphalt mixing systems.

- Design Patent Certificate – Protects our ergonomic and functional designs.

- CE Certification – Meets EU safety, health, and environmental standards.

See More Our Asphalt Mixing Plant Pictures Working Around the World

Not only in Indonesia — AIMIX asphalt mixing plants have been delivered to more than 130+ countries like the Philippines, Malaysia, Russia, Uzbekistan, and Kyrgzstan. Check out gambar asphalt mixing plant near me from different job sites! You’ll see how our asphalt processing plants perform in various climates and terrains, proving their quality, stability, and easy setup on site.

120TPH Stationary Ashplant plant for Selling Asphalt Aggregates in Malaysia

80TPH Mobile Asphalt Drum Plant for Asphalt Aggregates Production in Papua New Guinea

Bitumen Batch Mix Plant 80TPH for Road Building in Russia

80TPH Stationary Asphalt Mixing Plant for Road Building in the Philippines

60TPH Asphalt Batching Plant for Urban Road Building in the Philippines

120TPH Asphalt Batch Plant for Road Building in Jamaica

160TPH Asphalt Batching Plant for Highway Building in Kazakhstan

100TPH Batch Asphalt Plant for Road Aggregates in Kyrgzstan

80TPH Asphalt Production Plant for Road Building in the Philippines

40TPH Drum Mix Asphalt Plant for Road Repair in Fiji

Indonesia Asphalt Road Market Outlook 2025+: Key Trends & Opportunities

Indonesia’s asphalt road construction market is poised for steady growth at an estimated CAGR of 6.5% from 2025 to 2030, driven by large-scale infrastructure investments and urbanization. With rapid expansion ahead, knowing the market’s pulse helps you build smarter and win more contracts. Explore the key trends and opportunities shaping Indonesia’s road future.

| Indicator | Value | Notes |

|---|---|---|

| Projected Asphalt Demand (2030) | ~180 million tons/year | Up from ~120 million tons in 2024 |

| National Infrastructure Budget | $400+ billion (2020-2029) | Focus on toll roads, rural roads, urban networks |

| Asphalt Plant Capacity Growth | 8-10% CAGR | Increase in mobile and stationary plants |

| Urbanization Rate (2025) | ~55% | Growing demand in Jakarta, Surabaya, Medan |

| RAP (Recycled Asphalt Pavement) Usage | 10-15% of total asphalt mix | Supported by green policies |

Key Policy Drivers and Initiatives

- National Medium-Term Development Plan (RPJMN) 2020-2024 & 2025-2029: Prioritize road network expansion and upgrading. Asphalt road projects dominate the road budget allocation.

- Green Infrastructure Push: Government incentives encourage use of warm mix asphalt and recycled materials to reduce carbon footprint.

- Decentralization Policies: Support local governments to manage and maintain rural road asphalt paving projects.

- Public-Private Partnerships (PPP): To accelerate toll road development, increasing demand for reliable asphalt supply.

Market Segmentation and Regional Insights

| Segment | Characteristics | Key Regions |

|---|---|---|

| Highway & Toll Roads | High-quality, large-scale projects requiring robust, durable asphalt mixes | Java (Trans-Java Toll), Sumatra (Trans-Sumatra Toll) |

| Urban Roads | Smaller-scale, flexible paving; emphasis on fast construction and environmental compliance | Jakarta, Surabaya, Medan |

| Rural & Village Roads | Focus on cost-effective, locally produced asphalt mixes; use of mobile asphalt plants | Eastern Indonesia, Kalimantan, Sulawesi |

| Airport & Heavy Traffic | Specialized high-performance asphalt for durability under heavy loads | Major airports (Soekarno-Hatta, Juanda) |

Challenges & Opportunities

- Logistics Complexity: Indonesia’s archipelagic geography poses transport challenges, increasing the value of mobile and modular asphalt plants.

- Bitumen Price Volatility: Global oil price fluctuations impact asphalt raw material cost; local blending reduces risk.

- Labor Skill Gaps: Training and automation can improve operation efficiency and quality control.

- Sustainability Demand: Increasing government and client focus on green asphalt solutions offers a growing niche market.

Batch Asphalt Plant vs Continuous Asphalt Plant: Which is Right for You?

Selecting the right amp aspal mixing plant adalah crucial for the success of your road construction project. The choice between asphalt batch mix plants and continuous drum-type asphalt plants depends on several factors, including project scale, quality requirements, and budget. Here’s a detailed comparison to help you make an informed decision.

| Feature | Batch Asphalt Plant | Continuous (Drum) Asphalt Plant |

|---|---|---|

| Mixing Method | Mixes in separate, timed batches | Mixes materials continuously |

| Output Flexibility | Can adjust mix recipe frequently | Best for one consistent mix |

| Production Capacity | 40–400 t/h (ideal for city roads, highways) | 20–120 t/h (great for village, rural roads) |

| Initial Investment | Higher (starts from ~$50,000) | Lower (starts from ~$20,000) |

| Mixing Precision | High – suitable for complex projects (airport, etc) | Moderate – suitable for basic road projects |

| Footprint | Larger – needs more space | Compact – easy to install in tight areas |

| Mobility | Stationary/Mobile | Stationary/mobile – easier to relocate |

| Maintenance Needs | Slightly higher due to complexity | Lower, simple operation |

| Use in Indonesia | Common in big cities like Jakarta, Surabaya | Popular in rural areas, village road upgrades |

Still not sure which one fits your job site? 👉 Contact us today for free expert guidance tailored to your local project needs in Indonesia!

What Are the Main Asphalt Plant Components?

An amp asphalt mixing plant adalah a complex machine designed for the efficient production of asphalt mixes. This is just the fungsi asphalt mixing plant. Want to know more about bagian bagian asphalt mixing plant? Here’s its main asphalt plant parts and functions in the following.

- Batching System: Ensures precise measurement and mixing with ±0.5% aggregate and ±0.25% powder accuracy, delivering consistent asphalt quality.

- Drying System: Efficiently dries aggregates to the correct temperature, equipped with an automated control system for optimal operation.

- Combustion System: Provides fuel-efficient heat for drying, reducing costs through intelligent fuel management.

- Hot Material Lifting System: Moves hot aggregates smoothly to storage or mixing areas, aided by wear-resistant parts and predictive maintenance technology.

- Vibrating Screen: Filters out oversized particles to ensure only the right-sized aggregates are used in the mix.

- Hot Material Storage Bin: Maintains aggregate temperature and quality; cold aggregate bins increased by 20% capacity to reduce waiting time and boost productivity.

- Weighing and Mixing System: High-precision weighing with AI-powered controls; flexible operation modes (PC, touchscreen, buttons) ensure continuous, automated mixing.

- Asphalt Supply System: Delivers bitumen consistently, integrated with IoT remote monitoring to reduce faults and enable maintenance alerts.

- Powder Supply System: Adds powders and additives to enhance asphalt durability and performance.

- Dust Removal System: Telescopic dust pipes allow ±3cm installation tolerance; effectively captures dust for a cleaner environment and compliance.

- Finished Silo: Stores final asphalt products, designed with upgraded wear-resistant structures supporting million-ton outputs.

- Control System: Integrated smart control enables one-touch start/stop, simplifies 50-step operations into one, and supports IoT real-time monitoring for efficient management.

These komponen asphalt mixing plant work together to ensure that your asphalt batch plant operates smoothly and efficiently, delivering high-quality asphalt for your construction needs. In the following, here is an asphalt mixing plant layout/asphalt batch plant diagram picture. Let’s see the asphalt plant 3d model.

How Does An Asphalt Plant Work – A Step-by-Step Guide from the Inside

Hi there, I’m your trusted batch asphalt mixing plants. Every day, I roll up my sleeves to produce high-quality hot mix asphalt for highways, airport runways, and major infrastructure across Indonesia. Knowing the cara kerja asphalt mixing plant is essential for daily operation. Let me walk you through my smart and powerful proses produksi asphalt mixing plant—step by step!

Aggregate Feeding – I Start with Raw Materials

My enlarged cold aggregate bins—now 20% bigger—make sure I never run out during peak hours. I feed batu pecah, pasir, and abu batu into my system with the right proportions for each project.

Drying – I Heat and Prepare

Inside my drum dryer, I remove moisture efficiently while ensuring consistent heat (up to 180°C). It’s all automated—no guesswork here!

Dust Collection – I Stay Clean and Green

My extendable dust pipeline allows ±3cm of flexibility, making installation easy even in tight Indonesian sites. I capture fine dust through an eco-friendly filtering system, keeping emissions low and your site cleaner.

Screening – I Sort with Precision (Batch Type Only)

I use high-efficiency vibrating screens to classify hot aggregates by size. My modular structure makes screen changes quick and maintenance faster—even in the tropics.

Weighing – I Measure with Accuracy

My AI-based high-precision weighing system keeps errors within ±0.5% for aggregates and ±0.25% for bitumen and filler. You get consistent asphalt quality, every time.

Mixing – I Deliver Power and Speed

My “JinGang” turbo-mixing blades ensure powerful blending. I complete each batch in under a minute, boosting your production by 15% daily. The mixer is so durable, the blades can run up to 5 years without replacement!

Control – I Think for Myself

Thanks to my integrated smart control system, I simplify 50 manual steps into one button. From touchscreen to manual override, my triple-mode operation fits every operator style. I even remind you when maintenance is due via IOT remote monitoring!

Delivery – I’m Fast and Reliable

With my smooth unloading system, I load asphalt into waiting trucks or silos efficiently. And if you ever need data, all production logs are auto-stored and accessible remotely.

Asphalt Mixing Plant FAQs

Q1: What Are The Different Types Of Asphalt Mixing Plants?

Q2: How Long Will It Take To Produce The Asphalt Mixing Plant?

Q3: How Can I Get Remote Support For My Asphalt Plant Machine?

Q4: Can I Get The Spare Parts In Time?

Q5:How To Choose The Right Asphalt Mixing Plant?

Q6: What Are Common Uses for Asphalt?

- Road Construction: Used for building and resurfacing roads.

- Parking Lots: Ideal for creating durable parking surfaces.

- Airport Runways: Suitable for high-traffic areas due to its strength and durability.

Q7: How to Start an Asphalt Plant Business?

- Research the market: Check demand and competition in your area.

- Create a business plan: Define your goals, target market, and costs.

- Get funding: Estimate startup costs and secure financing.

- Choose a location: Find a site with good access to materials and transport.

- Buy equipment: Purchase a suitable asphalt mixing plant Indonesia from asphalt mixing plant manufacturers.

- Get permits: Obtain the necessary permits and licenses.

- Set up operations: Install the model asphalt plants for sale and hire staff.

- Market your business: Promote your services to potential clients.

- Start operations: Begin production and manage your business.

Q8: How to Install an Asphalt Plant

- Select the site: Choose a flat area with good access to materials and transport.

- Prepare the ground: Level the site and build a strong foundation.

- Assemble the plant: Set up the bitumen mixing plant components according to the manufacturer’s instructions.

- Connect utilities: Hook up electricity, water, and fuel lines.

- Test the jual amp plant: Run tests to ensure everything works correctly.

- Train your team: Teach your staff how to operate and maintain the bitumen plant for sale.

- Start production: Begin producing asphalt, monitoring for any issues.

Q9: Where Can I Buy an Asphalt Plant?

Q10: What is an Asphalt Plant?/what is Asphalt Mixing Plant?

Reliable Localized Service Support for Asphalt Plants in Indonesia

At AIMIX Indonesia, we deeply understand the challenges faced by contractors in Indonesia—from equipment setup to long-term maintenance. That’s why we provide comprehensive, on-the-ground support to ensure every customer feels secure, efficient, and confident when using our pabrik aspal. Below are six key service pillars tailored for the Indonesian market:

Dedicated Indonesian Service Team

- 3+ permanent service bases across Indonesia (Jakarta, Surabaya, Medan)

- 10+ full-time Indonesian-speaking engineers available for on-site support

- 48-hour average response time to most urban and semi-urban projects

With an in-country team, we ensure rapid deployment, clear communication, and no delays caused by language barriers or international coordination.

On-Site Installation & Technical Training

- Full plant installation included, completed within 10–15 working days

- Operator training sessions for 2–5 local staff, in Bahasa Indonesia

- Live testing, calibration, and commissioning by AIMIX technicians

From first-time setup to daily operation, we provide step-by-step support to ensure pabrik aspal is ready for real production with no guesswork.

24/7 Technical Assistance Available

- Hotline & WhatsApp support with local engineers—response within 1 hour

- Live video troubleshooting for electrical or mechanical faults

- 99% issue resolution rate without requiring customized parts

Whether your pabrik aspal operates in urban Java or rural Kalimantan, you can always reach our team for immediate solutions.

Local Spare Parts Inventory

- Spare parts warehouses in Jakarta and Palembang covering key regions

- Stock includes wear parts (burners, belts, sensors, motors, control units)

- 85% of replacement needs can be fulfilled within 3 days

With local warehousing, you avoid 2–3 week delays common with imported-only asphalt mixing plant suppliers—your production keeps running.

Project-Based Plant Customization

- Suitable for national toll roads, kabupaten roads, airport, and bridge works

- Optimized for tropical humidity and regional aggregate types (andesite)

- Options include different plants, based on road access and site scale

Asphalt mixing plant equipment suits your exact project—no overpaying for features you don’t need or struggling with under-spec models.

Flexible Payment Terms & Import Support

- Payment options include LC, TT with deposit, and installment plans

- We assist in BPOM, SNI, and customs clearance documentation

- Provide logistics plan including port unloading and inland delivery

Whether you’re working with government tenders or private funding, we help you plan financially and logistically from start to finish.

With AIMIX, you don’t just get an amp aspal terdekat—you get a trusted partner ready to grow with you across every province in Indonesia.

Build Better Roads? Let’s Talk Asphalt Plant!

Looking for a reliable China asphalt mixing plant in Indonesia? We as an outstanding perusahaan asphalt mixing plant China, have you covered—with quality machines, local support, and competitive harga AMP aspal. Whether you need a mini asphalt plant for village roads or a large unit for highway projects, we’re here to help. 📞 Contact us now for a free quote and expert advice—your project deserves the best!