Next-Gen Planetary Mixer Concrete Pump – 3× Mixing Capacity, Smart Control, Zero Downtime

All-in-One Boom Mixer Pump – 360° Mixing, 50% Wider Reach, 60% Faster Transfers

High-Pressure Trailer Pump – Stable Output, Long-Distance Delivery, Built for Tough Jobs.

Concrete pump adalah a construction equipment that delivers concrete efficiently, even in Indonesia’s tight urban spaces, remote islands. We provide 3 types of concrete pumps to help clients reach high-rises, bridges, and hard-to-access sites on time, and reduce labor issues. See how concrete pumps make construction faster, safer, and hassle-free.

Trusted Concrete Pump Project Stories Across Indonesia

Across Indonesia, many contractors are choosing concrete pumps to handle tough construction demands. From high-rises to remote island projects, our trailer, boom, and mixer concrete pumps have proven their value on real job sites. The concrete pump images show how clients use our concrete pumps to cut delays, reduce costs, and build with confidence.

ABT30C Diesel Trailer Concrete Pump for Housing Building

- Concrete Output: 30m³/h

- Engine: Diesel Type

- Location: In Dumai, Indonesia

- Project: House Construction

Customer Review: “I needed a reliable pump for our housing project in Dumai. The ABT30C Diesel Trailer Pump delivered concrete quickly and reached tight areas without hassle. It saved us time and reduced on-site labor—definitely a smart choice for local construction.”

ABT40C Diesel Concrete Trailer Pump for House Construction

- Concrete Output: 40m³/h

- Engine: Diesel Type

- Location: In Kupang, Indonesia

- Project: House Construction

Customer Review: “The 40cbm pompa kodok beton made our house construction in Kupang much easier. It reached tight corners, pumped concrete smoothly, and helped us finish faster with fewer workers. Very satisfied with the performance!”

AS-2.6 Carmixer and ABT40D Beton Pump for Home construction

- Concrete Output: 40m³/h Pump, 10.4m³/h Self Mixer

- Engine: Diesel Type

- Location: In Kalimatan, Indonesia

- Project: House Construction

Customer Review: “Using the AS-2.6 Carmixer with the ABT40D cement pump made our home construction in Kalimantan much smoother. The self mixer kept a steady supply, and the beton pump delivered concrete exactly where we needed. Highly recommended for local projects.”

ABT40C Diesel Trailer Concrete Pump for Floor Pouring

- Concrete Output: 40m³/h

- Engine: Diesel Type

- Location: In Manowari, Papur, Indonesia

- Project: Floor Pouring

Customer Review: “The ABT40C trailer pump cement handled our floor pouring in Manokwari smoothly. It reached every corner easily and kept the concrete flow consistent. Using it saved us time and effort—definitely a reliable choice for local projects.”

ABJZ40C Diesel Concrete Mixer Pump for Rural Housing Building

- Concrete Output: 40m³/h

- Type: Diesel Drum Mixer Type

- Location: In Medan, Indonesia

- Project: Rural Housing Building

Customer Review: “I used the diesel cement mixer pump for our rural housing project in Medan. The stationary concrete pump delivered concrete smoothly and consistently, and I was impressed with how stable and easy it was to operate, even on uneven terrain. It made the whole pouring process much more manageable.”

ABJZ40C Construction Concrete Pump Mixer for Bridge Building

- Concrete Output: 40m³/h

- Type: Diesel Drum Mixer Type

- Location: In Kupang, Indonesia

- Project: Rural Bridge Building

Customer Review: “The 40cbm diesel concrete mixer with pump delivered concrete steadily for our rural bridge project in Kupang. It reached hard-to-access spots easily and operated smoothly throughout the entire construction process.”

ABJZ40C Mixer Concrete Pump Jakarta for Seaside Facility Building

- Concrete Output: 40m³/h

- Type: Diesel Drum Mixer Type

- Location: In Jakarta, Indonesia

- Project: Build Facilities Seaside

Customer Review: “I used the ABJZ40C diesel cement mixer pump for our seaside facility project in Jakarta. It handled concrete delivery smoothly, even in challenging site conditions, and made the entire construction process much easier and more reliable.”

ABJZ40C Diesel Concrete Mixer Pump for Road Construction

- Concrete Output: 40m³/h

- Type: Diesel Drum Mixer Type

- Location: In Lampung, Indonesia

- Project: Small Road Construction

Customer Review: “For our small road construction project in Lampung, I relied on the ABJZ40C diesel concrete pump. It delivered concrete steadily and reached all the narrow areas easily, making the pouring process much smoother and more manageable.”

AJBT40C Truck-mounted Concrete Pump Mixer for Urban Building

- Concrete Output: 40m³/h

- Type: Diesel JS1000 Drum Mixer Type

- Location: In Jakarta, Indonesia

- Project: Urban Construction Building

Customer Review: “During our urban construction project in Jakarta, I used the AJBT40C truck-mounted mixer concrete pump equipment. It pumped concrete smoothly to high and tight areas, making it much easier to manage the workflow on a busy site.”

These projects across Indonesia demonstrate how concrete pouring machines handle real on-site challenges and keep construction running smoothly. Next, let’s look at the different concrete pump types in Indonesia and how each suits specific project needs.

What Are the Types of Concrete Pumps in Indonesia?

Concrete pump can be categorized based on fungsi concrete pump and applications. The main jenis concrete pump include concrete mixer pump, trailer pump, and boom pump. Each jenis pompa beton standar is designed to solve real construction challenges—helping you reach high floors, work in tight urban spaces, or deliver concrete to remote sites in Indonesia.

| Feature / Type | Concrete Trailer Pump | Concrete Mixer Pump (Pan/Planetary) | Concrete Boom Pump (Wheel/Crawler/Truck) |

|---|---|---|---|

| Primary Function | Efficient concrete pumping, needs external mixer | Mixes and pumps concrete on-site, ensures uniformity | Pump concrete to high or hard-to-reach areas, can mix on-site with pan mixer |

| Mixer Type | External or separate mixer | Pan/Planetary Mixer, dual-shaft for uniform mix | Planetary Pan Mixer integrated, dual-shaft optional |

| Max Concrete Output | 30–90 m³/h (varies by model) | 30–40 m³/h | 50–170 m³/h (depending on reach/boom type) |

| Conveying Distance | Vertical: 100–280 m, Horizontal: 300–1200 m | Vertical: 120–150 m, Horizontal: 300–600 m | Vertical: 8–50 m, Horizontal: 120–600 m |

| Mobility / Transport | Trailer-mounted, can be towed by truck/loader | Compact, wheel-mounted for easy site transfer | Wheel, crawler, or truck type; modular for long-distance transport |

| Applications | Housing, small/medium construction projects | High-strength concrete projects: bridge foundations, heavy equipment bases | Urban high-rises, bridges, rural housing, irrigation, river works |

| Key Advantages | Low cost, easy to operate, quick setup | On-site mixing reduces transport, ensures uniformity, handles C40+ concrete | Precise placement, covers difficult terrain, high efficiency, reduces labor |

| Ideal Users | Small to mid-sized contractors needing portable pumping | Contractors requiring uniform, high-strength concrete | Small crews to large contractors needing high reach or complex site access |

What is a Concrete Trailer Pump?

A concrete trailer pump is designed to deliver concrete efficiently over long horizontal distances and to elevated areas, mounted on a trailer for easy mobility. Perfect for Indonesian construction sites—from urban buildings to remote island projects—it provides precise, reliable concrete placement, with the option for vertical pumping when needed.

Concrete Trailer Pump Characteristics

- Kapasitas Concrete Pump: 30m³/h-90m³/h

- Aggregate Size: 10/50mm

- Engine: electric or diesel type

- Pumping system pressure: 28-32MPa

- Vertical Conveying distance: 100-280m

- Max. horizontal distance: 300-1200meters

- Application: Used in Indonesia for urban high-rises, bridges, roads, remote islands, and residential projects.

Concrete Trailer Pump Advantages

Trailer-mounted design ensures easy mobility, delivers concrete efficiently over long distances, operates steadily in tight spaces and challenging terrains, requires minimal maintenance, and keeps projects running smoothly.

What is a Concrete Mixer Pump?

A concrete mixer pump combines mixing and pumping in one unit, allowing on-site concrete production and direct delivery. It is available in Drum Mixer Type and Pan Mixer Type, suitable for different project needs. Ideal for Indonesian construction sites—from crowded Jakarta sites to remote islands —it delivers concrete quickly, precisely, and efficiently.

Drum Type Concrete Mixer Pump Introduction

- Models: ABJZ30C, ABJZ40C, ABJZ30D, ABJZ40D

- Concrete Output: 30/40m³/h

- Engine: electric or diesel type

- Mixing Mode: Drum Mixer

- Max. theoretical vertical distance: ≤150m

- Max. theoretical horizontal distance: ≤600m

- Application: for housing, roads, small bridges, and remote-site projects, providing on-site mixing and direct pumping even in areas with limited access or electricity.

Drum Type Concrete Mixer Pump Advantages

With flexible diesel or electric power, strong high-pressure pumping, compact design for easy moving, and durable low-maintenance parts, these pumps keep your projects running smoothly, on time, and without hassle.

Pan Mixer Type Concrete Mixer Pump Characteristics

- Models: ABJW30C, ABJW40C, ABJW60C

- Concrete Output: 30/40/60m³/h

- Engine: Diesel type

- Mixing Mode: Planetary Pan Mixer

- Max. theoretical vertical distance: 120m

- Max. theoretical horizontal distance: ≤600m

- Application: ideal for high-strength concrete applications such as bridges, heavy foundations, and small to medium infrastructure projects.

Pan Mixer Pump Advantages

Dual hydraulic planetary mixing ensures uniform C40+ concrete, while the large hopper and adaptive pumping reduce blockages by 70%. Intelligent controls and wireless operation cut labor and downtime by 30–40%.

What is a Concrete Boom Pump?

A concrete boom pump delivers concrete to high or hard-to-reach places using a hydraulic arm. It comes in Tire, Crawler, and Truck types, and can include a Pan Mixer for on-site mixing. Ideal for Indonesian sites—from urban high-rises to bridges and remote islands—it ensures precise placement, reduces labor, and keeps projects running smoothly.

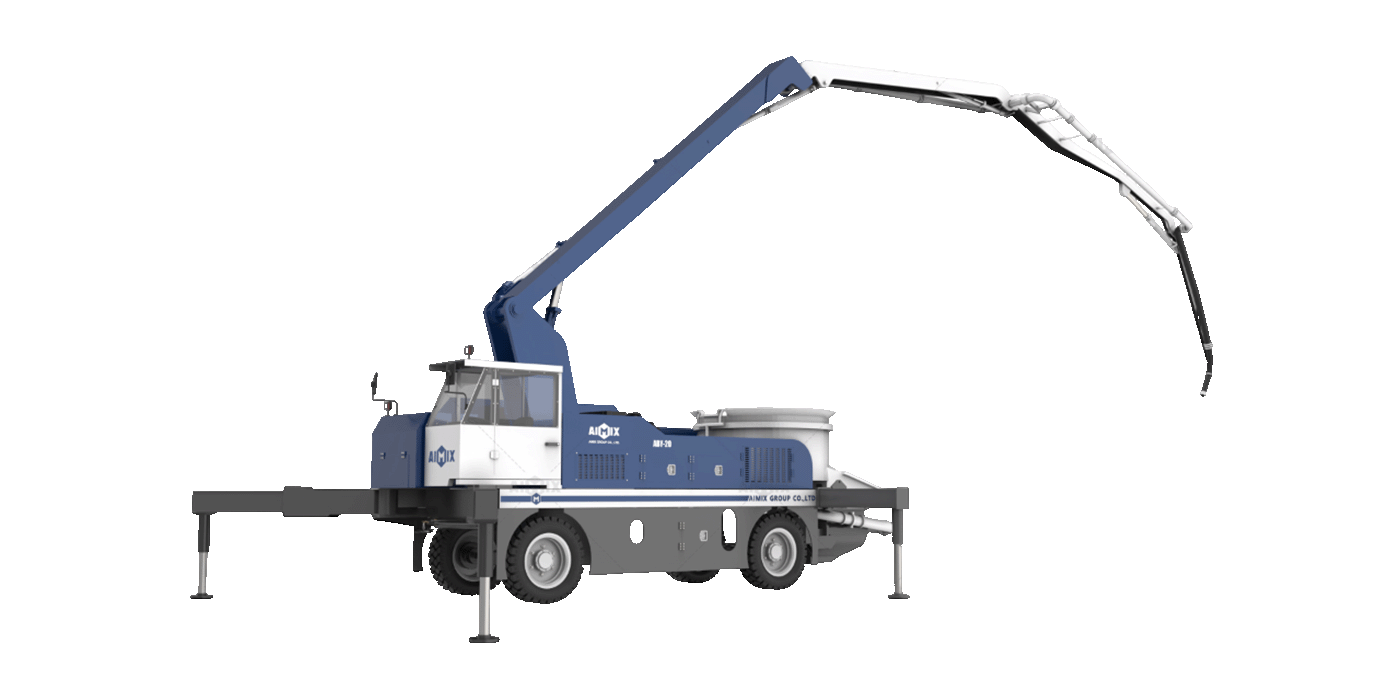

Wheel Type Boom Concrete Pump with Pan Mixer

- Reach Distance: 18m, 20m, 26m, 30m, 33m

- Hot Models: ABY20, ABY26

- Max Concrete Output: 89m³/h

- Boom sections: ≤5

- Mixer: Planetary Pan Mixer

- Applications: Rural housing, drainage projects

- Ideal Users: Small to mid-sized contractors needing mobility

Key Advantages of Wheel Type Boom Pump

- Flexible Mobility: Tire chassis suits flat/moderate roads, 60% faster transfer.

- Quick Startup: Ready-to-work on arrival, reduces waiting time by 30%.

- Efficient 360° Mixing: Improves concrete uniformity and density by 30%.

- 33m Boom: Covers narrow urban and underground sites, 50% larger radius.

- Low Vibration: Suspension cuts shock by 20%, extends machine lifespan.

Crawler Type Boom Pump with Pan Mixer

- Reach Distance: 8m, 15m, 18m, 20m, 25m

- Hot Models: ABY18

- Max Concrete Output: 50m³/h

- Boom sections: ≤4

- Mixer: Planetary Pan Mixer

- Applications: Mountain irrigation, farmland, river projects

- Ideal Users: Water conservancy and small mountain crews

Key Advantages of Crawler Type Boom Pump

- All-Terrain Capability: Climbs up to 35°, 60% better on mud and mountains.

- Wireless Remote: Enhances safety, reduces onsite personnel risks.

- Walk-and-Work: Pumps ≤15m boom can move and work, 25% less downtime.

- Hydraulic Suspension: Lowers vibration damage, increases lifespan by 15%.

- Dual-Shaft Mixing: Doubles output, ideal for fast pours in rough terrain.

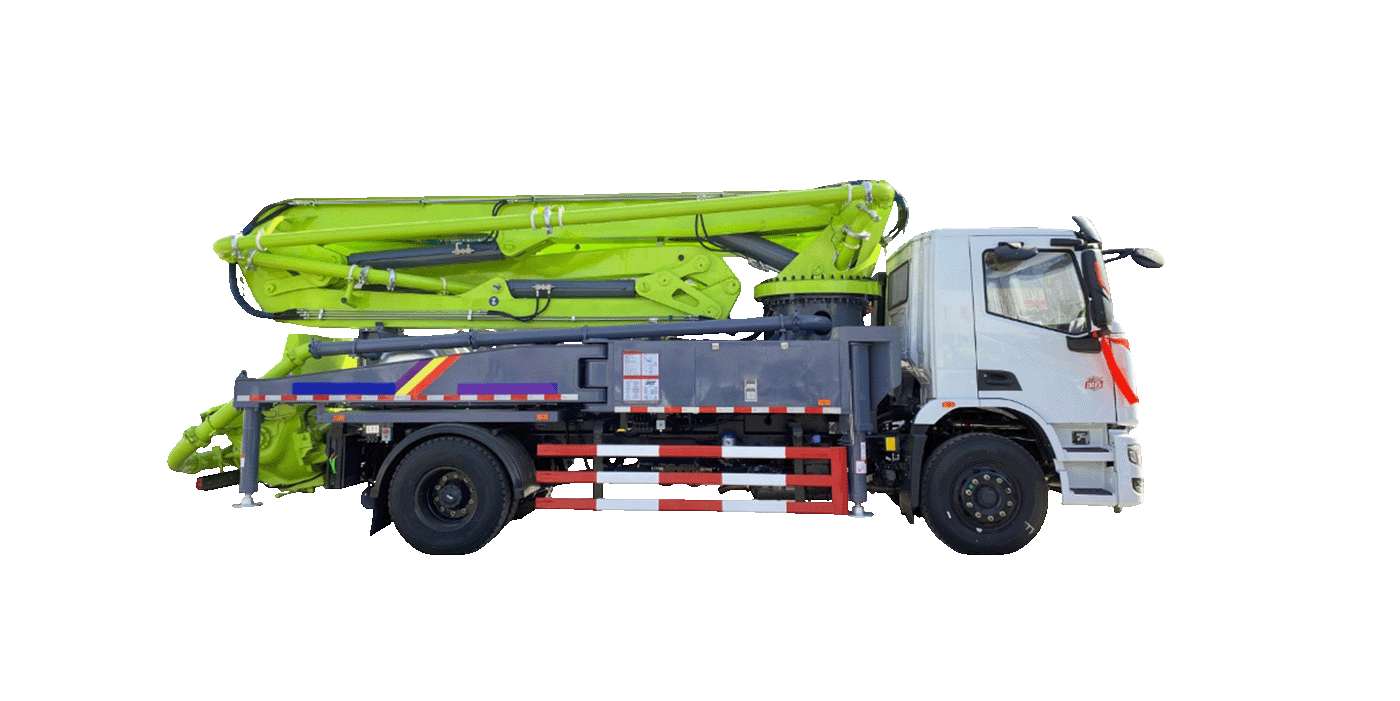

Truck Type Boom Pump with Pan Mixer

- Reach Distance: 26m, 30m, 33m, 38m

- Hot Models: ABY33

- Max Concrete Output: 120m³/h

- Boom sections: ≤5

- Mixer: Planetary Pan Mixer

- Applications: Urban buildings, highways, bridge construction

- Ideal Users: Large contractors focused on efficiency

Key Features of Truck Type Mobil Pompa Beton

- Fast Transport: Max speed 80 km/h, ideal for long-distance moves.

- Modular Design: Repairs 40% faster with quick-detach components.

- Integrated Mixer: Saves 20% site space, fits urban high-rise projects.

- Long Boom: Extends pumping radius by 50%, suits large jobs.

- Auto Diagnostics: Real-time monitoring reduces downtime by 15%.

Truck Type Boom Pump with Pan Mixer

- Reach Distance: 26m, 30m, 33m, 38m, 47m, 50m, 58m

- Hot Models: ABY33, ABY38

- Max Concrete Output: 170m³/h

- Boom sections: ≤5

- Mixer: Planetary Pan Mixer

- Applications: High-rise building construction, bridge projects

- Ideal Users: Batching plants and professional pumping firms

Truck Type Boom Concrete Pumper Advantages

- Lightweight Design: 15% weight reduction lowers transport costs.

- High Pumping Pressure: Up to 10 MPa, increases pumping distance by 20%.

- External Mixer Compatible: Easily connects to batching plants.

- Simplified Structure: Extends maintenance intervals by 25%.

- Energy Efficient: Fuel consumption reduced by 10%, saves costs.

By comparing trailer, mixer, and boom concrete pumps near me, Indonesian contractors can quickly see which type fits their project scale, terrain, and mobility needs. Next, we’ll explore detailed concrete pump specifications—covering output, boom reach, and mixer options—so you can choose the right concrete pump solutions for your site.

Spesifikasi Concrete Pump

To make an informed decision, it’s essential to understand high pressure concrete pump specifications. Max output, pumping pressure, boom reach, and mixer type all affect efficiency and site performance. Knowing these specs helps pick the pump that ensures smooth, fast, and reliable concrete placement. Let’s learn concrete pump specifications together!

Concrete Trailer Pump Specifications

| Items | Units | ABT40C | ABT60C | ABT80C |

|---|---|---|---|---|

| Max. theo. concrete output(H./L.) | m3/h | 26/40 | 45/87 | 45/84 |

| Max. concrete pumping pressure(H./L.) | Mpa | 10/8 | 13/7 | 16/7 |

| Distribution valve type | S | S | S | |

| Concrete cylinder diameter×stroke | mm | Φ180/1300 | Φ200/1650 | Φ200/1800 |

| Hopper capactiy × feeding height | L×mm | 400×1250 | 800×1400 | 800×1400 |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 |

| Diesel engine model | Weichai | Weichai | Weichai | |

| Electrical engineering power | KW | 82 | 129 | 176 |

| Rotate speed | r/min | 2200 | 2200 | 2200 |

| Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | Mpa | 32 | 32 | 32 |

| Mixing system pressure | Mpa | 10 | 10 | 10 |

| Max mixing speed | r/min | 25 | 25 | 25 |

| Capacity of oil tank | L | 370 | 560 | 560 |

| The biggest transportation is away from vertically(/Level) | m | 120/500 | 180/1000 | 260/1200 |

| Max. aggregate diameter | mm | Scree:40 | Scree:40 | Scree:40 |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 |

| Dimensions: length×width×height | mm | 4500×1850×1700 | 5800×2000×1750 | 6300×2100×2350 |

| Total weight | kg | 4500 | 6500 | 6900 |

Drum Type Concrete Mixer Pump Specifications

| Model | Units | ABJZ30C-8-66R | ABJZ40C-10-82R |

|---|---|---|---|

| Max. theo. concrete output | m3/h | 30 | 40 |

| Max. concrete pumping pressure(H./L.) | Mpa | 8 | 10 |

| Distribution Valve Type | S | S | |

| Concrete Cylinder Diameter×Stroke | mm | Φ140/1000 | Φ180/1000 |

| Hopper Capacity×Feeding Height | L×mm | 400×1200 | 400×1200 |

| Outlet Diameter | mm | Φ100 | Φ150 |

| Electrical Engineering Power | KW | 66 | 82 |

| Rotate Speed | r/min | 1800 | 2200 |

| Circuit Type | Open Circuit | Open Circuit | |

| Pumping System Pressure | Mpa | 28 | 32 |

| Mixing System Pressure | Mpa | 10 | 10 |

| Max Mixing Spped | r/min | 20 | 20 |

| Capacity of Oil Tank | L | 350 | 350 |

| The biggest transportation is away from vertically(/Level) | m | 120/400 | 150/600 |

| Max. Aggregate Diameter | mm | Φ100 | Φ125 |

| Dimensions: length×width×height | mm | 6000×2300×3150 | 6000×2350×3150 |

| Total Weight | Kg | 5500 | 6000 |

Pan Mixer Type Concrete Mixer Pump Specifications

| ABJW40C Concrete Pump with Planetary Mixer (Wireless Remote Control Operation) | |

|---|---|

| Model | ABJW40C |

| Max. theo. concrete output(m³/h) | 40 |

| Max. concrete pumping pressure(MPa) | 9 |

| Stirring oil pump | 45 |

| Mixing oil pump pressure(MPa) | 23 |

| Spare oil pump | 32 |

| Spare oil pump pressure(MPa) | 12 |

| Distribution valve type | S Valve |

| Concrete cylinder diameter × stroke(mm) | Ф180×1000 |

| Hopper capacity(L) | 600 |

| Outlet diameter(mm) | Ф150 |

| Diesel engine model | Weichai |

| Electrical engineering power(kW) | 82 |

| Rotate speed(r/min) | 2200 |

| Circuit type | Open circuit |

| Pumping system pressure(MPa) | 31.5 |

| Mixing system pressure(MPa) | 6 |

| Capacity of oil tank(L) | 350 |

| The biggest transportation is away from vertically (/Level)(m) | 100/400 |

| Max. aggregate diameter(mm) | Scree: 40/50 |

| Inside diameter of delivering pipe(mm) | Ф125 |

| Dimensions: length × width × height(mm) | 4500x2200x2100 |

| Total weight(Kg) | 5600 |

| Control Method(45 and 32 Pump) | Controlled by PLC |

Concrete Boom Pump Specifications

| Category | Parameter | Unit | ABY-20 Wheel Type(4WD Engineering Chassis) | ABY-26 Wheel Type(4WD Engineering Chassis) |

|---|---|---|---|---|

| Pumping Performance | Theoretical Concrete Output (High Pressure) | m³/h | 53 | 89 |

| Theoretical Concrete Pressure (High Pressure) | MPa | 9.5 | 9.5 | |

| Power System | Rated Power | kW | 110 | 135 |

| Rated Speed | rpm | 2000 | 2000 | |

| Hydraulic System | Hydraulic Oil Tank Capacity | L | 500 | 550 |

| Dimensions & Weight | Overall Dimensions (L×W×H) | mm | 6800×1900×3200 | ~7600×1900×3200 |

| Total Weight | T | ~13.0 | ~13.9 | |

| Max. Theoretical Delivery Distance | Different Pipes | m | Horizontal: 1000 / Vertical: 150(For Ø180mm) | Horizontal: 600 / Vertical: 80(For Ø125mm) |

| Boom System | Boom Type | - | RZ | RZ |

| Max. Vertical Reach | m | 20.5 | 25.45 | |

| Max. Horizontal Reach (Excl. 3m Hose) | m | 18.2 | 22.2 | |

| Boom & Outriggers | 1st Boom Length | mm | 6300 | 5850 |

| 2nd Boom Length | mm | 5000 | 5800 | |

| 3rd Boom Length | mm | 2100 | 5500 | |

| 4th Boom Length | mm | 2600 | 2000 | |

| 5th Boom Length | mm | / | 3050 | |

| Turret Rotation Angle | ° | ±180° (Left/Right) | ±180 | |

| Outriggers | Front Outrigger Span (Two-Stage Telescopic) | mm | 5180 | 5180 |

| Rear Outrigger Span (H-Type) | mm | 4120 | 4120 | |

| Front/Rear Outrigger Longitudinal Span | mm | 6750 | 6750 / 5987 | |

| Chassis | Wheelbase | mm | 3500 | 3800 |

| Travel Speed | km/h | 20-30 | 20-30 | |

| Diesel Engine | Rated Power | kW | 110 | 135 |

| Max. Speed | r/min | 2000 | 2000 | |

| Gradeability | Max. Climbing Angle | ° | 30 | 30 |

Concrete Mixing and Pumping Solutions

For the best building results, combining concrete equipment often plays a role in 1+1>2. We offer various concrete pumping solutions to meet different construction needs.

Whether you need long-distance transport, precise placement, or on-site mixing, our betonpump solutions are designed to boost your project’s success.

Concrete Mixer Truck + Pump Trailer

Self-Loading Concrete Mixer + Trailer Pump

Concrete Mixer Pump + Wheel Loader

Mixer Pump + Batching Machine + Loader

Concrete Mixer + Trailer Pump

Pairing concrete pumpers with mixers or other equipment ensures smooth, efficient workflow on any Indonesian site—from city high-rises in Jakarta to rural bridges in Sulawesi. To plan your investment wisely, the next step is understanding what is the concrete pump price.

What is the Concrete Pump Price in Indonesia?

Wondering how much a concrete pump will cost for your Indonesian project? Whether you need a compact mixer or trailer pump for tight village sites or a high-output boom pump for urban high-rises, AIMIX concrete pump prices range from $15,000 to $400,000. Here we will show you the concrete pump machine price ranges for different pompa concrete models.

Understanding these jual concrete pump price ranges is the first step to finding a solution that fits your budget and project needs. Next, let’s explore how to choose the right concrete pump sale for your site and application.

How to Choose the Right Concrete Pumping Machine in Indonesia

Choosing the right cement pumping machine for sale is critical for Indonesian contractors, as it directly affects construction efficiency, project cost, and concrete quality. With diverse project types—urban high-rises, rural housing, and bridges—matching the equipment to site conditions and project requirements is key. Here’s a practical guide as below.

Understand Your Project Type and Site Conditions

- Urban High-Rises and Bridges: Space is limited, and concrete needs to reach high elevations.

- Recommended: Truck-type or wheel-type concrete boom pumps with long reach (26–58 m) and integrated pan mixers.

- Why: Long boom sections allow precise placement without extra manpower. Compact designs save site space up to 20%.

- Rural Housing and Drainage Projects: Often involve narrow roads, soft ground, or limited access.

- Recommended: Wheel-type mini boom pumps or trailer pump beton.

- Why: Tire or trailer mobility enables 60% faster transfer and easy relocation. Small footprint and easy towing reduce operational challenges.

- Mountainous or Remote Areas: Uneven terrain, mud, and long transport distances are common.

- Recommended: Crawler-type boom pumps or trailer pumps with diesel engines.

- Why: All-terrain capability climbs up to 35°, dual-shaft or planetary pan mixers ensure steady output, while diesel power avoids unreliable electricity.

Consider Concrete Type and Pumping Requirements

- Strength & Mixability: For high-strength concrete (C40+), use pan or planetary mixer pumps. They provide uniform mixing and avoid segregation, essential for heavy equipment foundations and bridges. For ordinary concrete, roller drum or simpler trailer pump concrete suffice, saving cost.

- Output & Pumping Pressure: Small to mid-sized projects: 30–40 m³/h, pumping pressure 8–10 MPa. Large-scale projects: 120–170 m³/h, pumping pressure up to 10 MPa.

- Quantitative planning ensures continuous delivery and avoids downtime, especially in hot Indonesian climates where concrete can set quickly.

Choose Power Source and Mobility

- Diesel vs. Electric: Diesel betonpumps: Best for sites without stable electricity, remote areas, or mobile jobs. Electric concrete pumps: Ideal for urban sites with reliable power, lower fuel costs, and quieter operation.

- Mobility Considerations: Trailer cement pumps: Can be towed by a small truck, suitable for scattered small projects. Wheel-type boom pumps: Fast transfer on flat roads, 60% faster than crawler types. Crawler-type boom pumps: Superior on mud, hills, and rough terrain.

Evaluate Reliability and Maintenance

- Hydraulic System: Independent circuits, quality pumps (Kawasaki, Parker), and multi-stage filtration extend life and reduce maintenance.

- Mixing System: Planetary pan or dual-shaft mixers improve uniformity by 30–40% and reduce blockages.

- Safety Features: Remote control, pressure feedback, and automatic alerts reduce risks for operators.

- Cooling & Lubrication: Water or air-cooled hydraulic oil, automatic lubrication ensures continuous operation in hot and humid Indonesian climates.

Optimize Cost vs. Efficiency

- Trailer concrete transfer pumps: Low investment, flexible for scattered projects, save transport cost.

- Mixer pump for cement: Combine mixing and pumping, reduce need for extra concrete trucks, saving 20–40% on logistics.

- Boom cement concrete pumps: Higher upfront cost but increase speed, reduce labor, and allow precise placement, saving project time by 15–30%.

Local Support and After-Sales Service

- Choose concrete pump machines from brands with Indonesian service points, concrete pump spare parts availability, and responsive technical support.

- Machines with widely recognized engines (Weichai, Cummins) and hydraulic components ensure quick repairs and reduced downtime.

Now that you know how to choose the right cement pump machine for your Indonesian projects, it’s time to see why investing in your own concert pump makes smart business sense. Let’s dive into the key advantages of bringing a cement pumping machine on board.

Why Investing in Your Own Concrete Pump Makes Smart Business Sense

Owning a concrete pump machine for sale in Indonesia is more than just having equipment on site—it’s a strategic move. From improving efficiency to cutting costs, the right investment can directly boost your project capabilities and business growth. Here are six key reasons why contractors are choosing to invest in their own concrete and pumps.

Boost Project Efficiency

Owning a hydraulic cement pump increases pouring speed by up to 40%, ensuring timely completion of high-rise, bridge, or infrastructure projects.

Lower Operational Costs

Avoid repeated rental fees, which can reach IDR 50–150 million per month for medium-sized pumps, saving substantial money annually.

Expand Service Capability

Handle multiple projects simultaneously, especially in remote or island locations where rental availability is limited.

Higher Profit Margins

Self-ownership reduces dependency on third parties and labor, increasing project profit margins by an estimated 15–25%.

Flexible Deployment

Adapt quickly to urban, rural, or mountainous construction sites, reducing downtime by up to 30% compared to rented pumps.

Long-Term Investment

Concrete pump models can operate reliably for 8–12 years, providing continuous returns and supporting sustainable business growth.

Knowing the advantages of investing in a concrete pressure machine in Indonesia, the next step is to understand how these machines work. Learning their working principles will help you select the most suitable type for your projects and ensure maximum efficiency and return on investment.

How Does a Concrete Pump Work?

Cara kerja concrete pump? A concrete pump works by transferring concrete from the mixer to the desired location. See the bagian bagian concrete pump diagram in the following. Here’s how a concrete pump works(cara kerja pompa beton):

Preparing the Concrete

- First, materials like cement, sand, gravel, and water are mixed in a concrete mixer. The mix must have the right consistency for pumping.

Filling the Hopper

- The mixed concrete is poured into the pump’s hopper. The hopper stores the concrete and feeds it into the pump.

Suction and Pumping

- Inside the pump, two pistons work together. One piston pulls concrete from the hopper, while the other pushes it into the pipeline.

Pipeline Delivery

- The concrete moves through a pipeline to the construction site. The pipeline’s length and angle can be adjusted to ensure the concrete reaches the exact spot.

Precise Pouring

- At the end of the pipeline, the concrete is poured directly into place. The operator controls the flow and direction to ensure accurate placement.

After understanding how a concrete pump works, the next key step is learning how to operate it efficiently. Proper operation not only ensures smooth concrete placement but also maximizes the machine’s lifespan, reduces maintenance costs, and guarantees timely project completion.

How to Operate a Concrete Pump?

Learning the operation procedure of a mesin concrete pump is essential to improve efficiency. Here is the concrete pump video and character introduction about concrete pump operation in the following.

Prepare the Equipment

Ensure the s valve concrete pump Indonesia is set up on stable ground. Check all hoses, pipes, and connections for any issues.

Prime the Pump

Before starting, prime the pump by running a small amount of water or slurry through it. This helps the concrete flow smoothly.

Load the Concrete

Pour the mixed concrete into the pump’s hopper. Make sure it’s the right consistency to avoid clogging.

Start Pumping

Begin the pumping process by slowly increasing the pressure. Monitor the flow to ensure everything is working smoothly.

Guide the Concrete

Use the pump’s controls to direct the concrete through the hoses or boom. Position the end of the hose or boom at the desired location.

Adjust Flow

Control the speed and volume of the concrete to match the needs of the project. Make adjustments as necessary.

Clean the Pump

After completing the job, flush the pump with water to clean out any remaining concrete. This prevents buildup and ensures the concrete pressure pump is ready for the next use.

After learning how to operate a concrete pump vehicle, it’s equally important to understand the key precautions during daily operation. Following proper procedures not only ensures safety and machine longevity but also maximizes efficiency on Indonesian construction sites. Keep reading to discover practical tips for safe and smooth operation.

Precautions During Daily Operation/Pengoperasian Concrete Pump

01Daily Lubrication Check

What to Do: Inspect the lubricating grease level in the box every day.

Why It’s Important: A consistent decrease in grease indicates proper lubrication. If the level drops less than usual, it may mean a lubrication point is blocked.

Action Required: Check and clear any blockages immediately.

02Water Tank Maintenance

What to Do: Replace the water in the tank daily before starting the jual pompa beton.

Water Level: Ensure the water level just covers the piston rod.

Why It’s Important: Proper water level prevents damage to the proximity switch. If the water level is too high, it can spill and cause issues.

03Hopper Screw Nut Tightening

What to Do: Regularly tighten the large screw nut at the back of the concrete hopper.

Why It’s Important: A loose nut can lead to damage of the glasses plates and cutting loop, especially during cleaning.

Action Required: Use the wrench from the toolbox to tighten the nut securely.

04Screw Inspection and Tightening

What to Do: After each workday, check all screws on the beton pompa.

Why It’s Important: Loose screws can lead to operational problems.

Action Required: Tighten any loose screws to ensure the pump remains in good working condition.

After learning the key precautions during daily operation of your pompa beton, it’s essential to address common questions that can impact efficiency, safety, and maintenance. Explore our concrete pump FAQs to get practical tips and solutions for smoother, worry-free operation.

Concrete Pump FAQs

Applications Of Concrete Pump

- High-Rise Buildings: Efficiently pumping concrete to great heights for skyscrapers and tall structures.

- Bridge Construction: Delivering concrete precisely for bridge piers and spans.

- Residential Projects: Facilitating the construction of foundations, walls, and floors in homes.

- Industrial Projects: Handling large volumes of concrete for factories, warehouses, and other industrial buildings.

- Tunnel and Mining Work: Pumping concrete into tunnels and mining shafts for support and reinforcement.

- Precast Concrete: Assisting in the production of precast concrete elements in factories.

Where to Buy a Concrete Pump

- Manufacturer Websites: Direct purchase ensures quality and support. Check AIMIX for a range of reliable options.

- Local Dealers: Convenient for quick purchases and after-sales service.

- Online Marketplaces: Offers competitive prices, but verify seller credibility.

- Construction Equipment Auctions: Potential for good deals, but inspect concrete pump for sale near me thoroughly.

- Referrals: Trust recommendations from industry peers to find reputable sellers.

Who Makes the Best Concrete Pump?

What Type of Pump Is Best for Concrete?

What Is the Lifespan of a Concrete Pump?

How Much Pressure Does a Concrete Pump Need?

What Is the Difference Between a Concrete Pump Truck and a Line Pump?

What Concrete Pump Is Appropriate for High-Rise?

What Is a Concrete Pump Used for?

What Is the Best Concrete Pump?

How Profitable Is a Concrete Pumping Business?

- Can a concrete pump business be profitable?

- Constant Demand: Construction needs concrete pumping all the time, ensuring steady income.

- Maximized Efficiency: Concrete pumping is fast and needs less labor, so you earn more by completing more jobs.

- High ROI: Equipment is costly, but you make back the money quickly and earn more.

- Low Downtime, High Earnings: Maintain your concrete pump Surabaya to avoid breakdowns, complete more jobs, and increase profits.

- Multiple Revenue Streams: Offer various pompa conveyor beton and services to attract more projects and boost revenue.

- Sustained Growth: Smart management leads to growth and long-term success.

How to Start a Concrete Pumping Business?

- Research and Plan: Conduct market research to understand demand. Create a detailed business plan outlining goals, budget, and strategy.

- Register Your Business: Choose a business name and legal structure. Register your business and obtain necessary licenses and permits.

- Secure Financing: Determine startup costs including equipment and operational expenses. Explore financing options like loans or investors.

- Purchase Equipment: Buy or lease concrete pumping trucks and other necessary tools. Ensure high pressure concrete pump is reliable and meets industry standards from concrete pump dealers near me.

- Hire Skilled Staff: Recruit experienced operators and support staff. Provide training to ensure safety and efficiency.

- Market Your Services: Develop a marketing strategy using online and offline methods. Network with contractors and construction companies.

- Ensure Compliance: Adhere to safety regulations and industry standards. Maintain proper insurance coverage for liability and workers’ compensation.

Why Buying a Concrete Pump Instead of Renting One?

- Starting a concrete pumping business can be a lucrative venture, offering numerous advantages over renting equipment. Here are some compelling reasons to consider owning your own concrete hydraulic pump.

- Cost Efficiency: Over time, buying a cement transfer pump can be more cost-effective than renting, especially for frequent use. Eliminates recurring rental fees.

- Availability: Owning a beton pump ensures it’s available whenever needed, avoiding potential scheduling conflicts with rental companies.

- Customization: Allows for customization and modification to meet specific business needs.

- Asset Value: Ownership adds value to your business assets, which can be beneficial for financial reporting and obtaining loans.

- Operational Control: Greater control over maintenance and operation, ensuring the pump is always in optimal condition.

- Long-Term Investment: Provides long-term savings and potential tax benefits through depreciation. Therefore, the overall cost make it more cost-effective than the harga sewa concrete pump mini.

- Branding: Having your own hydraulic pump for concrete with your branding can enhance professional image and marketing efforts.

Reliable Concrete Pump Service Across Indonesia

Building in Indonesia can be challenging—remote sites, urban traffic, and tight project schedules demand reliable equipment and fast support. AIMIX provides complete concrete pump services across Indonesia, with local expertise, a wide range of concrete pumping machines, and tailored solutions that keep your projects running smoothly, on time, and on budget.

Local Support

With offices and agents across Indonesia, we offer timely assistance, ensuring your pump concrete for sale remains operational and your projects stay on track.

Warehousing

Our local warehouses ensure quick access to spare parts and concrete pumping equipment, reducing downtime and keeping your projects running smoothly.

Fast and Efficient Service

Thanks to our local presence, we guarantee quick delivery, setup, and support tailored to the unique needs of Indonesian construction sites.

Customized Solutions

We also provide solutions tailored to your specific needs, recommending the right mesin concrete pumps for sale to ensure project success.

Choose Us, Improve Efficiency

AIMIX provides a variety of concrete pumps for sale to suit different concrete pumping needs. As a top Chinese concrete pump manufacturer, we offer full-service support and concrete pumping equipment supplies in Indonesia. Contact us to find the perfect beton pump for your project and ensure its success with AIMIX Indonesia.