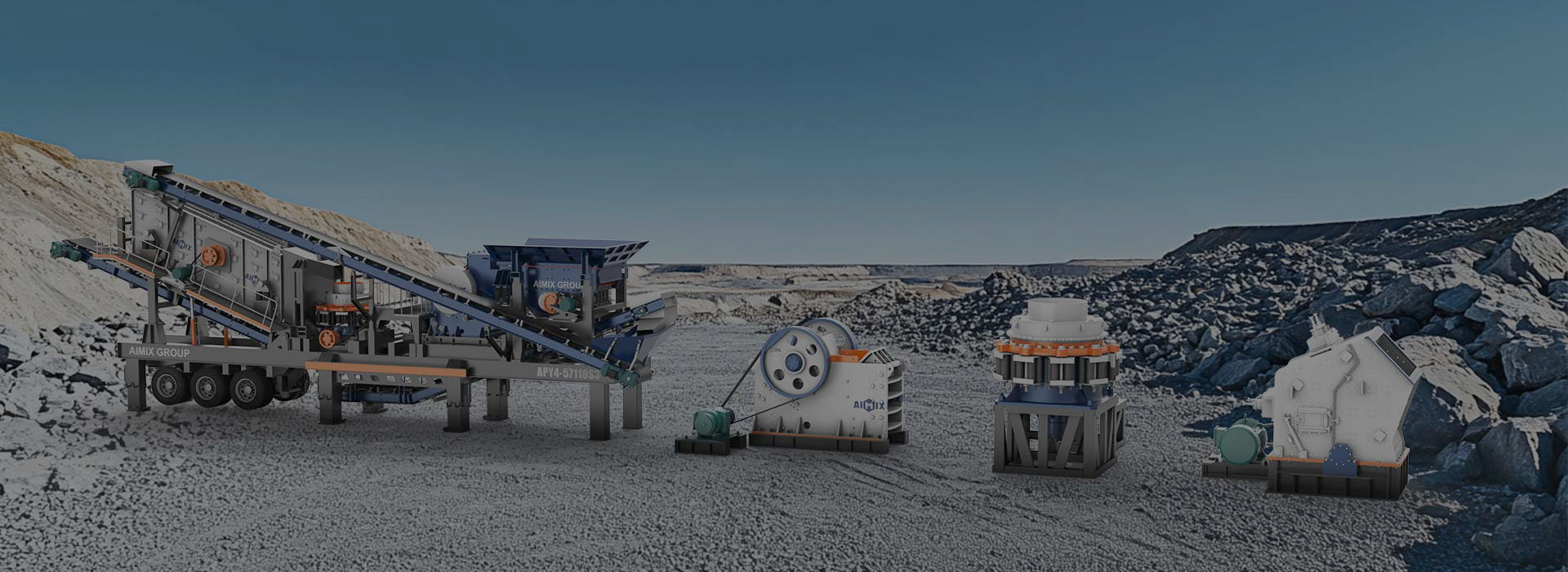

Smart Crusher Plant Solutions for Indonesian Projects

One-click start & intelligent operation — high productivity with less manual work

Modular design for flexible crusher machine combinations — adapt to any jobsite

Trusted by Fortune Global 500 — proven in large-scale infrastructure projects

Crusher Plants for Sale Fast Shipment in Surabaya

Fast delivery from local warehouses — no import delays

On-site inspection & testing before shipping

Save time and cost — no need to wait for overseas sourcing

Local Professional Support You Can Rely On

Authorized agents and service teams across Indonesia

Indonesia-speaking engineers — easy communication, zero barriers

End-to-end support — installation, training, and maintenance made easy

What is crusher plant? Crusher plant adalah essential for reducing raw material size in mining, aggregates, and construction waste recycling. The right crushing plant and equipment improves efficiency, cuts costs, and ensures a steady supply of quality materials—helping Indonesian businesses succeed across Java, Sumatra, Kalimantan, and beyond.

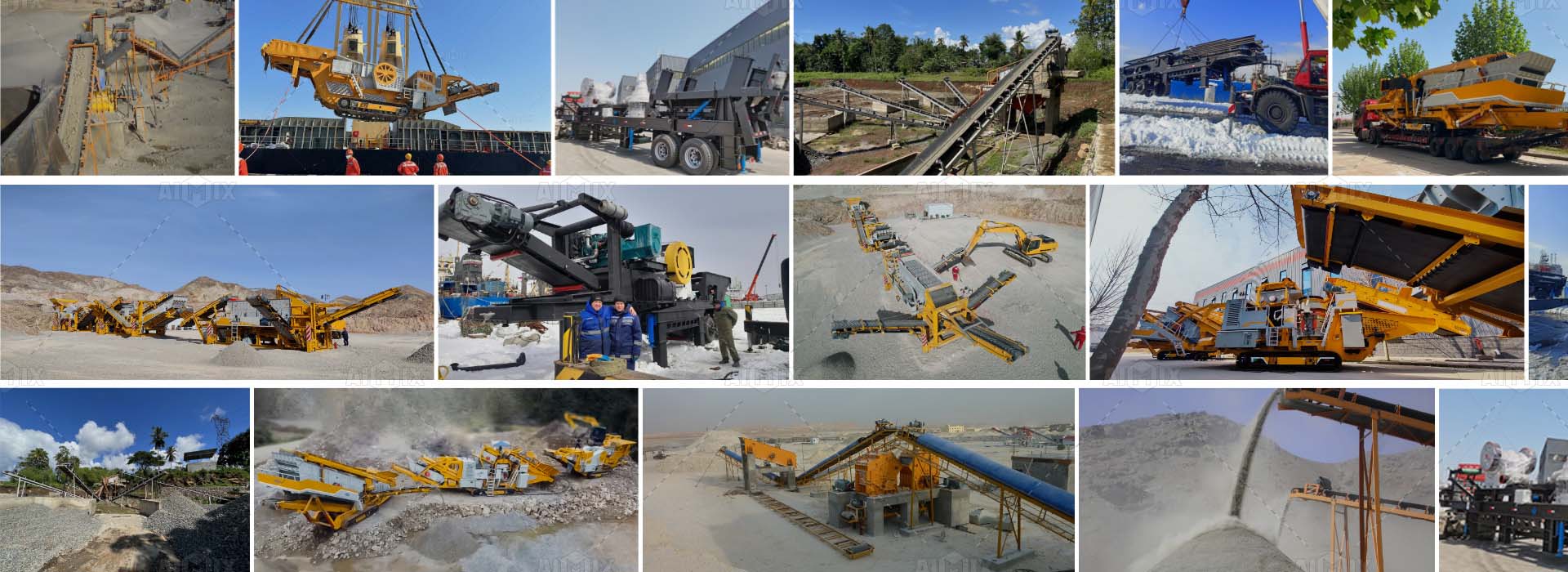

Crusher Plant Projects Across Indonesia – Proven On-Site Performance

From Kalimantan to Java, many local clients in Indonesia have chosen our crusher plants to handle mining, aggregates, and construction waste. Why? Because our crushing machines fit local needs, work reliably, and help get the job done faster. Here’s how these crushing plants perform on real job sites in Indonesia and global regions.

Limestone Crushing Plant Projects in Tuban

200TPH Primary Crushing Plant for Crushing Limestone

- Location: in Tuban, Indonesia

- Capacity: 200TPH

- Feeding Size: ≤500mm

- Output Size: 0-5-20mm

- Application: Produce Fine Aggregates in Paper Industry

- Configuration: Jaw Crusher Batu + Feeder + Vibrating Screen + Conveyor Belt

- Customer Review: “The limestone crusher plant works just like we expected—stable and easy to use. AIMIX team was helpful from day one. We’re really happy with the results.”

Granite Crushing Plant Projects in Sukabumi

4-in-1 Mobile Crusher Plant in West Java

- Location: in West Java, Indonesia

- Capacity: 100TPH

- Feeding Size: ≤630mm

- Output Size: 5-10-20-40mm

- Application: Produce Various Aggregates in Road Projects

- Configuration: Jaw Crusher, Cone Crusher and Screener, Vibrating Feeder, PLC Control Box, etc.

- Customer Review: “We move between sites and mobile crusher saves us so much setup time. The remote control is easy to manage even with a small team.”

Andesite Crusher Plant Project in Medan

Portable Jaw Crusher Plant in Medan

- Location: in Medan, Indonesia

- Capacity: 30TPH

- Feeding Size: ≤340mm

- Output Size: ≤10mm

- Application: for Road Base Aggregates

- Configuration: Belt Aggregate Conveyor, Jaw Crusher, Mobile Chassis + Vibrating Feeder

- Customer Review: “The portable jaw crusher helped us crush local stone into high-quality road base on-site. The machine is easy to move, and fits our Medan road project perfectly!”

Crushing Solutions for Mining, Aggregates, and Waste Recycling

Different materials and working environments require different crushing setups. Whether you are working in a mining site, a quarry, or an urban construction zone, the choice of crushing plant equipment should reflect the type of material, production scale, and on-site conditions. Below are common use cases from the field.

Crusher Plant Solutions in Mining: Enhancing Material Processing Efficiency

In many parts of Indonesia—such as Papua, Kalimantan, and Sulawesi—mining projects often face remote terrain, limited infrastructure, and hard-to-crush materials. A stable, wear-resistant mining crusher plant is essential to keep production running smoothly with minimal downtime. The solutions below are designed to meet the demands of these environments.

200T Stationary Crushing Plant for Crushing Gold Ore

- Raw Material: Gold ore

- Feeding Size: 630mm

- Output Size: 0-5mm

- Capacity: 200TPH

- Main Configurations: APJ-7510E Jaw crusher + Simmons spring cone crusher + Hydraulic roller crusher + 7*Screw conveyor + Vibrating screen + De-ironing seperator + Vibration feeder

260T Tire Mobile Crusher Plant Machinery for Crushing Copper Ore

- Raw Material: Copper ore

- Feeding Size: 0-720mm

- Capacity: 260-300TPH

- Output Size: 0-20-50mm

- Main Configurations: APY2-110J mobile jaw crusher + APY2-400M mobile cone crusher + Belt Conveyors + APG-4913W Vibrating feeder + APS-2460Y2 Vibrating screen

300 tph Crusher Plant Mobile for Crushing Iron Ore

- Raw Material: Iron ore

- Capacity: 300TPH

- Feeding Size: 750mm

- Output Size: 0-20-40-80mm

- Main Configurations: APY2-110JMobile Jaw crusher + APY2-440D mobile cone crusher plant + APG-4913W Vibrating feeder + APS-2460Y2 Vibrating screen

800TPH Chrome Ore Mining Crusher Machine Plant

- Raw Material: Chrome Ore

- Feeding Size: 720mm

- Capacity: 800TPH

- Output Size: 0-5-10-30-37.5-75mm

- Main Configurations: APJ-160V Jaw crusher + 2*APC-440D/3*APC-660D cone crusher + 3*Vibrating feeder + 5*Vibrating screen + 17*Belt conveyor + 4*De-ironing seperator

Crusher Plants in Aggregate Production: Meeting High Demand for Construction

From Java’s busy construction zones to Sumatra’s infrastructure projects, aggregate producers must process local stone types efficiently to meet project deadlines. The right aggregate crusher plant helps maintain output quality while adapting to the hardness and volume of different materials. See how we match crusher construction machine solutions to working conditions.

50T Stationary Crusher Machine Plant for Crushing Marble

- Capacity: 50TPH

- Output Size: 0-20mm

- Feeding size: 0-400mm

- Raw Material: Marble/River stone

- Application: decorative concrete and low-strength construction

- Main Configurations: APJ-5075E Jaw crusher + APC-75C Compound cone crusher + Vibrating feeder+ Vibrating screen + Belt conveyor*7

60TPH River Crushing and Screening Plant

- Output Size: 0-5-12-22mm

- Material: River Stone

- Feeding size: 500-600mm

- Capacity: 60-100TPH

- Application: Concrete Batching Plant for general concrete and road construction

- Main Configurations: APY4-57110S2 4-in-1 Mobile Crusher Plant(APJ-5070E Jaw Crusher/APC-110C Cone Crusher/Vibrating Feeder/Belt Conveyor/Vibrating Screen)

100TPH Limestone Crushing Plant for Making Sand

- Output Size: <5mm

- Material: Limestone

- Feeding size: <400mm

- Capacity: 100-150TPH

- Application: sand/general concrete and road construction

- Main Configurations: APZS-2028 Mobile VSI Crusher Plant+ APY3-1214F mobile impact crusher + Belt Conveyor + Vibrating Screen

100T-150T Pebble Mobile Rock Crusher Plant

- Output Size: 1/4,2/4,3/4 mm

- Raw Material: Pebble

- Feeding size: <600mm

- Capacity: 150TPH

- Application: high-strength concrete and road construction

- Main Configurations: APY2-110J Mobile Jaw Crusher + APY2-200C Mobile Cone Crusher + Conveyor Belt

150T Basalt Mobile Screening and Crushing Plant

- Material: Basalt

- Output Size: 0-5-20-40-70mm

- Feeding size: <630mm

- Capacity: 150-200TPH

- Main Configurations: APY2-7510J mobile jaw crusher + APY2-200M mobile cone crusher + Belt Conveyor

200T Granite Crushing Plant

- Material: Hard Rock(Granite)

- Feeding size: <630mm

- Capacity: 200TPH

- Output Size: 0-1/4-3/8-3/4-G1

- Main Configurations: APJ-7510E Jaw crusher + APC-430D Single cylinder hydraulic cone crusher + APG-4911W Vibrating feeder + APS-1860Y4 Vibrating screen + Belt conveyor

Crushing Solutions in Construction Waste Recycling: Supporting Sustainable Development and Reusing Resources

In fast-growing urban areas like Jakarta or Surabaya, demolition waste management is a rising concern. Crushing and recycling on-site saves both transport costs and landfill space. Mobile and flexible systems are especially valuable in tight, changing urban job sites. The following solutions are made to support this kind of work.

30-60tph 3-in-1 APY-3 1010F Construction Waste Mobile Impact Crusher

- Material: Concrete Waste

- Capacity: 20-30TPH

- Output Size:0-10mm

- Feeding size: 500mm

- APY3-1010FMobile Impact Crusher (APF-1010H Impact Crusher + APG-3090W vibrating feeder + APS-1548Y Vibration Screen + Belt Conveyor)

80-150tph 3-in-1 APY-3 1315F Construction Waste Mobile Impact Crusher

- Material: Construction Waste

- Capacity: 150TPH

- Output Size:0-10-20-40mm

- Feeding size: 400*400*700mm

- APY3-1315FMobile Impact Crusher (APF-1315H Impact Crusher + APG-4211W vibrating feeder + APS-2160Y Vibration Screen + Belt Conveyor)

What Types of Crusher Plant Adalah Used in Crushing Solutions?

In Indonesia, crushing projects vary widely depending on location, material, and scale. The two main types of crusher plants—stationary and mobile—offer different advantages depending on these factors. Choosing the right type crushing plants for sale helps improve efficiency and reduce overall cost.

Stationary Type Crusher Plant for Long-term, High-volume Production

- Capacity: 30-1200 TPH

- Feed Size: ≤700mm

- Suitable for long-term projects with varying locations and durations.

- Applications: Mining, quarrying, construction, and other industries

Static Crushing Plant Features

- Fixed installation, designed for continuous operation

- Includes full crushing, screening, and conveying systems

- Higher initial setup cost, but lower long-term operational cost

- Requires more space and stable infrastructure for jobsites

- Large-scale mining operations in Kalimantan and Papua

- Major quarries in Sumatra supplying regional infrastructure projects

- Commercial aggregate plants with stable material sources

Mobile Type Crusher Plant for Temporary, Scattered, or Flexible Project Sites

- Capacity: 16-300TPH

- Types: Tire/Crawler Type

- Finished Product(mm): 0-5, 5-10, 10-20, 20-25, above

- Application: Road construction, quarry, mining, recycling industry, etc.

Portable Crushing Plant Features

- Easy to transport and quick to set up

- Suitable for on-site crushing and rapid relocation

- Lower upfront requirements, flexible layout

- Quick relocation with 3-axle mobile design

- Urban construction waste recycling in Jakarta, Surabaya

- Short-term road or bridge projects across Java and Sulawesi

- Sites with limited access or spread-out raw materials

Mobile Type Crusher Plant Specifications

Mobile Jaw Crusher Specification

| Model | APY2-57J | APY2-69J | APY2-750J | APY2-110J |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-4211W | APG-4211W |

| Crusher model | APJ-5075E | APJ-6090E | APJ-7510E | APJ-110V |

| Maximum feed size (mm) | 425 | 500 | 630 | 650 |

| Silo volume (m3) | 4 | 5.3 | 7 | 7 |

| Iron separator model (optional) | RCYD(C)-6.5 | RCYD(C)-6.5 | RCYD(C)-8 | RCYD(C)-12 |

| Tire configuration | Parallel double shaft | Parallel double shaft | Parallel three shafts | Parallel three shafts |

| Main belt conveyor model | B650×8.5m | B800×8.5m | B1000×10m | B1000×10m |

| Side out belt conveyor model (optional) | B500×4m | B500×4m | B650×5m | B650×5m |

| Generator power (kW) (optional) | 120 | 160 | 200 | 250 |

| Production capacity (t/h) | 45-100 | 60-160 | 110-320 | 250-400 |

| Transport Length (mm) | 12500 | 12750 | 13270 | 13200 |

| Transport width (mm) | 2600 | 2600 | 2850 | 3000 |

| Transport height (mm) | 3950 | 3950 | 4200 | 4400 |

| Weight (t) | 28 | 39 | 57 | 65 |

Mobile Cone Crusher Specification

| Model | APY2-110C | APY2-160C | APY2-200C |

|---|---|---|---|

| Crusher model | APC-110C | APC-160C | APC-200C |

| Vibrating screen model | APS-1848Y | APS-1860Y | APS-2160Y |

| Maximum feed size (mm) | 160 | 200 | 215 |

| Tire configuration | Parallel double shaft | Parallel double shaft | Parallel double shaft |

| Feeding belt conveyor model (optional) | B650 | B800 | B1000 |

| Output belt conveyor model (optional) | B500 | B650 | B650 |

| Under-sieve belt conveyor model | B650 | B800 | B1000 |

| Generator power (kW) (optional) | 240 | 280 | 320 |

| Production capacity (t/h) | 50-230 | 80-390 | 120-420 |

| Transport Length (mm) | 13800 | 13800 | 14500 |

| Transport width (mm) | 3000 | 3000 | 3000 |

| Transport height (mm) | 4400 | 4400 | 4500 |

| Weight (t) | 32 | 37 | 42 |

4-in-1 Mobile Crusher Plant Specification

| Model | APY4-4660S | APY4-4690S | APY4-57110S | APY4-6912S |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3090W | APG-3090W | APG-3896W |

| Primary crusher model | APJ-4060E | APJ-4060E | APJ-5070E | APJ-6090E |

| Secondary crusher model | APC-600Y | APC-900Y | APC-110C | APF-1214 |

| Vibrating screen model | APS-1237Y | APS-1548Y | APS-1848Y | APS-1848Y |

| Tire configuration | Parallel three shafts | Parallel three shafts | Parallel three shafts | Parallel three shafts |

| Return belt conveyor model | B500 | B650 | B800 | B1000 |

| Feeder belt conveyor model | B500 | B650 | B00 | B1000 |

| Under-sieve belt conveyor model | B650 | B800 | B1000 | B1200 |

| Production capacity (t/h) | 16-40 | 16-65 | 50-100 | 60-160 |

| Transport length (mm) | 15500 | 16500 | 16500 | 16500 |

| Transport width (mm) | 2800 | 2850 | 2950 | 2950 |

| Transport height (mm) | 4200 | 4200 | 4200 | 4200 |

| Weight (t) | 41 | 45 | 53 | 50 |

Mobile Impact Crusher Plant Specification

| Model | APY3-1010F | APY3-1210F | APY3-1214F | APY3-1315F |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-3896W | APG-4211W |

| Crusher model | APF-1010H | APF-1210H | APF-1214H | APF-1315H |

| Vibrating screen model | APS-1548Y | APS-1848Y | APS-1860Y | APS-2160Y |

| Tire configuration | Parallel three shafts | Parallel three shafts | Parallel three shafts | Parallel three shafts |

| Return belt conveyor model | B650 | B650 | B800 | B1000 |

| Feeder belt conveyor model | B650 | B800 | B800 | B1000 |

| Under-sieve belt conveyor model | B800 | B800 | B1000 | B1000 |

| Production capacity (t/h) | 70-150 | 100-285 | 150-350 | 180-500 |

| Transport length (mm) | 13000 | 15800 | 15800 | 16500 |

| Transport width (mm) | 2500 | 2550 | 2550 | 3000 |

| Transport height (mm) | 4200 | 4500 | 4500 | 4500 |

| Weight (t) | 41 | 45 | 53 | 60 |

Crusher Machines – Core Equipment for Efficient Crushing Locally

In any crushing operation, the crusher machine for sale is the core component. Choosing the right type helps you process materials more efficiently, reduce operational costs, and meet specific project demands. In Indonesia, where materials range from hard mining ores to construction waste, understanding each mesin penghancur type is key to successful project execution.

Jaw Crusher – Primary Crushing Machine for Hard and Large Materials

Jaw crushers are commonly used in mining and quarrying projects across Kalimantan, Papua, and Sumatra. They are ideal for breaking down large, hard rocks into smaller pieces at the first crushing stage. With a simple structure and strong crushing power, jaw crushers are reliable even in tough site conditions.

Jaw Crusher Vehicle Technical Parameters

- Types: APJ-E, APJ-V, APJ-X Series

- Capacity: 1-800t/h

- Max Feeding Size: ≤ 1000mm

- Output Size: 15-300mm

- Applicable Materials: River pebble, granite, basalt, iron ore, quartzite, and other medium-hard to hard rocks

Jaw Crusher Units Key Features

- Large Feed Opening: Can handle larger materials with strong crushing force.

- Wedge Adjustment: Easy to adjust discharge size and avoid over-crushing.

- Durable Design: Made with strong materials for longer lifespan and fewer repair.

- Shock Absorbers: Reduce vibrations and extend the crusher equipment life.

- Integrated Motor: Saves space, lowers land costs, and simplifies installation.

Cone Crusher – Stable Performance for High-Quality Aggregates

Cone crushers are perfect for secondary or tertiary crushing, especially when producing uniform, well-shaped aggregates. The cone crusher is widely used in infrastructure and road projects on Java and Sumatra, where consistent particle size and durability are required.

Cone Crusher Technical Parameters

- Capacity: 5-1200t/h

- Feeding Size: 10-350mm

- Output Size: 3-63mm

- Types: Single Cylinder/Multi-cylinder Hydraulic Type|Spring Type|Compound Type

- Applicable Materials: Granite, iron ore, limestone, and other medium to high hardness rocks

Cone Crusher Key Features

- Efficient Crushing: Produces uniform output size with high efficiency.

- Strong Structure: Made with durable materials for longer service life.

- Multiple Models: Available in different types for various crushing needs.

- Intelligent Control: Automatically adjusts discharge size and prevents overload.

- Cost-effective Maintenance: Reduces maintenance costs with a simple design.

Impact Crusher – Flexible and Efficient for Medium-Hard Materials

Impact crushers are ideal for processing materials like limestone, concrete waste, and bricks. The impact crusher can crush using high-speed impact force and are often used in mobile crushing setups, especially in urban areas like Jakarta or Surabaya, where recycling and fast on-site processing are important.

Impact Crusher Technical Parameters

- Types: APF, APF-V, APF-H Series

- Capacity: 20-900t/h

- Max Feeding Size: <700mm

- Output Size: 5-180mm

- Applicable Materials: River pebble, granite, limestone, slag, construction waste, and other medium-hard materials

Impact Crusher Key Features

- Large Feed Opening: Can accommodate larger materials for better processing.

- Heavy Rotor: Increases durability and resistance to wear.

- Hydraulic Adjustment: Easy to adjust discharge size for better efficiency.

- Modular Design: Lowers maintenance costs and makes repairs quicker.

- Low Maintenance: Simple design for less maintenance and downtime.

VSI Crusher – Ideal for High-Quality Sand Production

Vertical Shaft Impact crushers are used to produce high-quality artificial sand and fine aggregates. In Indonesia, the sand making machine is widely applied in areas where natural sand is limited or river sand mining is restricted. VSI crushers equipment are especially useful in concrete production, precast factories, and projects that demand consistent sand shape and size.

VSI Crusher Technical Parameters

- Types: APV, APV-X Series

- Capacity: 60-750t/h

- Max Feeding Size: 30-65mm

- Output Size: 0-4.75mm

- Applicable Materials: Artificial sand production, fine aggregate shaping

VSI Crusher Key Features

- Good Sand Making: Efficient at crushing large materials into fine sand.

- Better Particle Shape: Produces well-graded, low-angularity sand with smooth edges.

- Energy Efficient: Lowers energy consumption while maintaining high output.

- Versatile: Works with a variety of materials, especially for sand production.

- Smart Control: Automatically adjusts settings for optimal performance.

- Easy to Maintain: Simple design for easy maintenance and part replacement.

- Space Saving: More compact compared to traditional crushing methods.

How Much Is A Crusher Plant in Indonesia?

The price of buying a crusherplant in Indonesia varies depending on a number of factors, including crusher type, capacity, configuration requirements, and crusher machine manufacturers brand. To ensure you get the best crusher plant machine for your project, here are crusher plant price ranges and some key factors and to help you feel more confident in your decision.

Crusher Plant Price List

| Products | Price Range |

|---|---|

| Jaw Crusher | $6,000-$235,800 |

| Cone Crusher | $23,000-$233,300 |

| Impact Crusher | $27,000-$72,300 |

| Sand Making Machine | $28,700-$83,500 |

| Mobile Crushing Plant | $550,000-$2,300,000 |

Key Factors Influencing Crushing Plant Price

- Type & Capacity: Bigger mesin crusher and higher output mean higher cost.

- Plant Configuration: More crusher machines = higher investment.

- Brand & Quality: Trusted brands usually offer better durability and after-sales service.

- Shipping & Installation: Local delivery and setup costs also impact your total budget.

Necessary Information When Sending A Quote?

- What raw materials do you want to crush (e.g., basalt, limestone)?

- How big are the input sizes?

- What final sizes do you need (e.g., 0–10mm, 10–20mm)?

- How many tons per day/hour do you want to produce?

- What is the main use (e.g., road base, concrete aggregate)?

📞 Contact AIMIX now for a tailored quotation and local service in Indonesia. We help you choose the best crusher plants for sale based on your needs and budget.

What Materials Are Commonly Crushed in Indonesia?

In Indonesia, a wide variety of raw materials are crushed to support mining, infrastructure, and construction projects. From hard mining ores in Kalimantan to abundant aggregates across Java and recycled waste in urban areas, local crushing needs vary by region—making the right mesin penghancur solution essential for efficiency and profitability.

What Mining Ores Are often Crushed?

Indonesia is rich in mineral resources, making ore crushing essential for mines. In regions like Kalimantan, Papua, and Sulawesi, materials such as gold ore, iron ore, copper ore, and bauxite are commonly processed on-site to support local smelters and exports. Efficient crushing solutions help reduce transportation costs and improve downstream processing.

| Material Pictures | Types | Main Regions | Estimated Reserves / Availability | Typical Applications | Material Characteristics |

|---|---|---|---|---|---|

| Gold Ore | Papua (Grasberg), North Sumatra | >3,000 tons Au content (Indonesia ranks top 10 globally) | Gold bars, jewelry, electronics, investment | Very hard, high specific gravity, contains sulfides |

| Copper Ore | Papua (Grasberg, Wabu Block) | >35 million tons Cu (among world’s largest) | Electrical wiring, motors, export metal | Medium-hard, metallic, sulfide/oxide mix |

| Iron Ore | Central & East Kalimantan, Sulawesi | ~400 million tons, mostly hematite & magnetite | Construction steel, iron pellets | Dense, high Fe content, strong magnetism |

| Bauxite Ore | West Kalimantan, Riau Islands | >1.2 billion tons, high-grade trihydrate | Alumina production, export to China | Clay-rich, sticky, medium density |

What Stones Are often Crushed for Producing Aggregates?

With rapid development across Java, Sumatra, and Sulawesi, demand for quality aggregates continues to grow. Crushing andesite, basalt, granite, and limestone is essential for producing road base, concrete, and asphalt materials. Local quarries rely on durable crusher plants to ensure consistent particle shape and gradation for large-scale public works.

| Material Picture | Types | Main Regions | Estimated Reserves / Availability | Typical Applications | Material Characteristics |

|---|---|---|---|---|---|

| Andesite | Java (West Java, Yogyakarta), Sumatra | Highly abundant, regulated by provincial mining offices | Asphalt mix, concrete aggregate, road base | Hard, angular, excellent interlock |

| Basalt | West Sumatra, Bali, Nusa Tenggara Timur | Present in volcanic zones, suitable for export | High-strength pavement, rail ballast, dams | Dark, fine-grained, very strong |

| Granite | Bangka Belitung, Lampung, South Sumatra | >200 known quarries, export potential to Singapore | Building foundation, bridges, high-load substructure | Coarse crystalline, extremely hard |

| Limestone | Sumatra, East Java, South Kalimantan | Several billion tons (cement-grade reserves) | Cement clinker, lime powder, filler for concrete | Soft to medium-hard, good workability |

What Construction Wastes Are often Crushed?

Urban development in cities like Jakarta, Surabaya, and Medan generates large volumes of construction waste. Crushing concrete, brick, and asphalt waste helps reduce landfill pressure and lowers material costs for new projects. Crushing solutions are widely used to turn demolition waste into reusable aggregates for roads, buildings, and utilities.

| Material Picture | Types | Main Regions | Estimated Reserves / Availability | Typical Applications | Material Characteristics |

|---|---|---|---|---|---|

| Concrete Waste | Jakarta, Surabaya, Bandung, Medan | 5–8 million tons/year (based on construction volume) | Recycled coarse aggregate, road base, embankments | Irregular size, mixed rebar, high variability |

| Brick Waste | Urban demolition zones (Java) | Increasing with housing regeneration | Subbase, landfill cover, non-structural fill | Brittle, porous, absorbs water |

| Asphalt Waste | Road repair projects nationwide | Several million tons/year (growing RAP use) | Reclaimed Asphalt Pavement (RAP), recycled binder | Bitumen-coated, sticky when heated |

🎥 Watch How Our Crusher Plants Work Locally

Want to see real crusher plant projects in action? This video showcases our crusher plants operating across Indonesia—from Java to Papua. You’ll see how we crush hard stone, produce high-quality aggregates, and support local clients with fast delivery and expert service. 📺 Click to watch more Youtube videos and discover why more Indonesian customers choose us!

How a Crusher Plant Works – Based on Indonesian Project Needs

If you’re running a construction or quarry project in Indonesia—whether it’s road building in Medan or a housing project near Jakarta—you’ll need crushed stones. A stone crusher plant helps you turn raw rock into usable aggregates, on site, at the sizes you actually need. Here’s what really happens in a typical crushing station:

Raw Stone In, Productivity Out

Shaping the Output

Screening What You Need

Final Product, Ready for Use

Keeping It Clean

See the crushing plant flow chart together!

How to Start a Crusher Plant in Indonesia: Key Steps for Local Success

Starting a crusher plant equipment in Indonesia involves more than just equipment—it requires planning, permits, and smart localization. Here are the core steps:

Market & Material Analysis: Identify your target materials (e.g., limestone in East Java, granite in Sulawesi, or river stone in Sumatra) and demand from local construction projects.

Legal & Environmental Permits: Secure izin usaha pertambangan (IUP) or Izin Lingkungan as required by the Indonesian government. Engage with local authorities for land and operation permits.

Choose the Right Crushers: Select fixed or mobile crushers machine based on jobsite mobility, raw material hardness, and production capacity.

Site & Utilities Setup: Ensure stable power (grid or generator), water access, and enough working space for material stockpiling.

Local Staffing & Maintenance Planning: Train a local team for operation and daily maintenance. Partner with a local service provider for support.

Pro Tip: Many successful Indonesian crushing businesses choose ready-to-install crusher plants stocked in Surabaya or Jakarta to shorten setup time and reduce import risks. Need help selecting the right plant crusher machine configuration? [Contact our local experts →]Get A Quote

📌 Where Crushed Materials Are Used in Indonesia

Crusher plants power key projects across Indonesia. Here’s where your aggregates go:

🛣️ Toll Road Construction – Trans-Java & Trans-Sumatra

- Project: Trans-Java Toll Road (Batang–Semarang, Solo–Kertosono)

- Use: Crushed stone used as road base, sub-base, and asphalt mix aggregate

- Why it matters: Continuous demand for high-quality aggregates in long-span infrastructure

🏗️ Patimban Deep Sea Port, West Java

- Project: One of Indonesia’s national strategic port projects

- Use: Crushed materials for port pavement, retaining walls, and logistics roads

- Why it matters: Requires durable aggregates to withstand heavy cargo operations

🏙️ Public Housing & Apartment Projects – Jakarta, Surabaya

- Project: Rusunawa (low-cost apartments) & TOD housing near LRT stations

- Use: Aggregates in concrete blocks, foundations, and paving

- Why it matters: Urban growth creates constant demand for concrete-ready materials

⚙️ Nickel Smelter Zones – Morowali & Weda Bay Industrial Parks

- Project: IMIP (Morowali) and IWIP (Weda Bay) – Indonesia’s top nickel processing hubs

- Use: Crusher plant aggregates used in plant foundations, road construction, and site grading

- Why it matters: Massive, long-term industrial operations need stable aggregate supply

🌊 Way Sekampung Dam, Lampung Province

- Project: National water reservoir and flood control project

- Use: Crushed stone used for dam embankments, slope protection, and drainage layers

- Why it matters: Infrastructure resilience depends on strong, weather-resistant materials

♻️ Construction Waste Recycling – Jakarta & Surabaya Urban Projects

- Project: Urban road renewal and building demolition reuse programs (e.g., Jakarta Smart City Revitalization, Surabaya Green Infrastructure Initiative)

- Use: Crushed concrete reused for road base layers, paving bricks, and non-structural concrete

- Why it matters: Reduces construction waste, lowers material costs, and supports Indonesia’s circular economy goals

📩 Need materials for your upcoming project in Indonesia? Contact us to get a crushing equipment solution tailored to your site, scale, and material needs.

🌍 Crusher Plant Projects Around the World

Explore how our crusher plant for sale performs in different countries worldwide. From the Philippines to Uzbekistan, Kenya to Saudi Arabia—our machines are working hard in real projects, producing reliable results across all terrains.

✅ Proven performance in diverse conditions

✅ Trusted by global customers in over 100 countries

✅ Inspiring solutions for your own crushing needs

📷 Browse the images to see real installations and get project ideas!

One-on-One Crusher Plant Services in Indonesia

We are committed to providing local support to help you set up, operate, and maintain crusher plants anywhere across Indonesia. Whether your project is in Java, Sumatra, Kalimantan, or Papua, we offer tailored solutions, fast delivery, and expert service to ensure your crushers machine run smoothly and efficiently. Let’s see what we do for you as one of professional crusher machine suppliers.

Customized Crusher Solutions

- Designed specifically for your material type and project needs

- Suitable for crushing stone or construction waste materials

- Includes feeding systems, crushing screening plant, and control units

Detailed 3D Plant Layout Design

- Provides a clear 3D map showing exact equipment placement

- Helps you plan site layout and workflow efficiently

- Reduces errors before the actual installation process

Professional Equipment Selection Advice

- Recommend mobile or stationary crusher plants for your location

- Choose the right model with capacity from 30 to 1200 tons per hour

- Ideal for mining, road construction, or recycling applications

Local After-Sales Team Based in Jakarta

- Available 24/7 to support installation and maintenance needs

- Communicate easily in Bahasa Indonesia and English

- Quick professional help via phone, WhatsApp, or on-site visits

Nationwide Partners Across Indonesia

- Skilled engineers ready in Jakarta, Surabaya, Papua, Batam, and others

- Provide fast local training, installation, and repair services

- Minimize machine crusher downtime with prompt, reliable support

Ready Stock Crusher Plants & Spare Parts

- Mesin crusher and spare parts stocked in Surabaya and Jakarta

- Customers can visit warehouses to inspect equipment before buying

- Fast delivery and easy replacement of parts to keep crush plants running

Ready to Start Your Crushing Project in Indonesia?

We, as one of leading crushing plant manufacturers, offer reliable crusher plant solutions tailored to your needs and budget. Whether you’re starting new or expanding, we’re here to help you succeed. 📩 Contact us today for a free design and quote — let’s build your crushing business together!