Local Service in Indonesia: Fast Response, On-Site Support, Worry-Free Operation

Stock available in Jakarta & Surabaya, ready to deliver

Bahasa Indonesia team support: from quote to installation

Spare parts & technician service covering all major islands

4-in-1 Tire-Type Mobile Crusher Plant: Flexible Combination, Smarter Crushing on the Move

Modular design: switch between impact crusher & sand maker

Triple-axle mobility + ROSTA vibration damping, stable & durable

Self-cleaning iron remover to prevent crusher damage

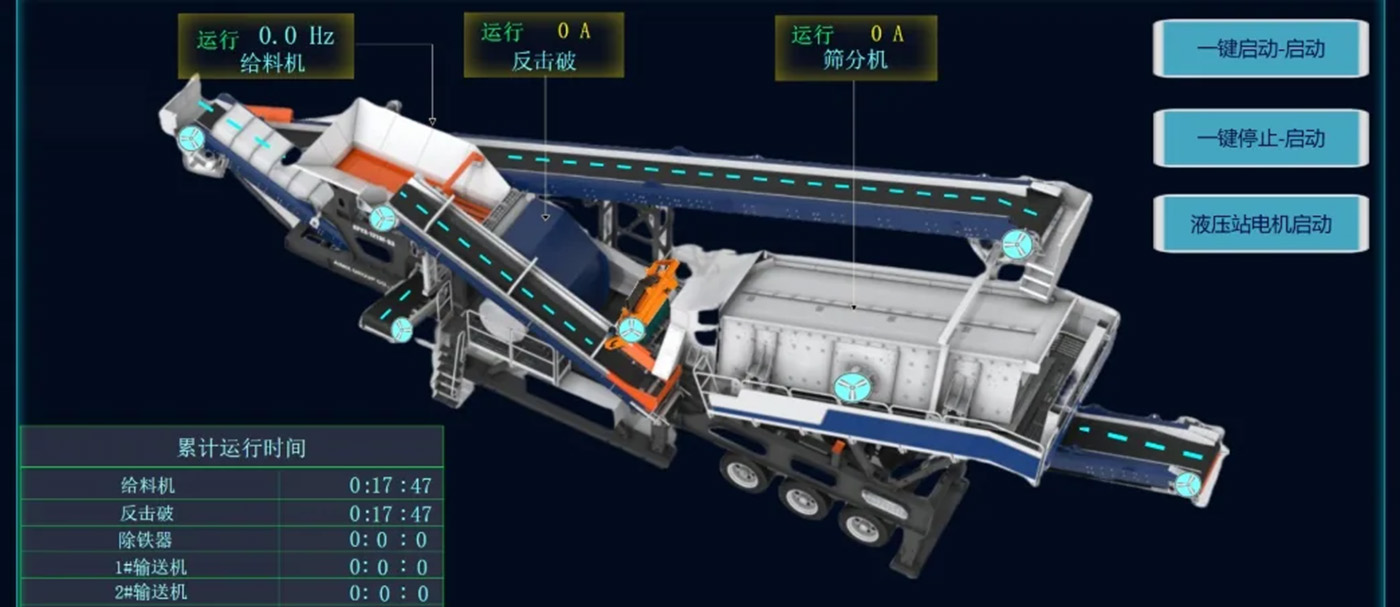

3-in-1 Mobile Impact Crushing Plant: Efficient Crushing Solution for C&D Waste Recycling

One-touch start, PLC + manual control, easy operation

Integrated feeding, crushing & screening, compact footprint

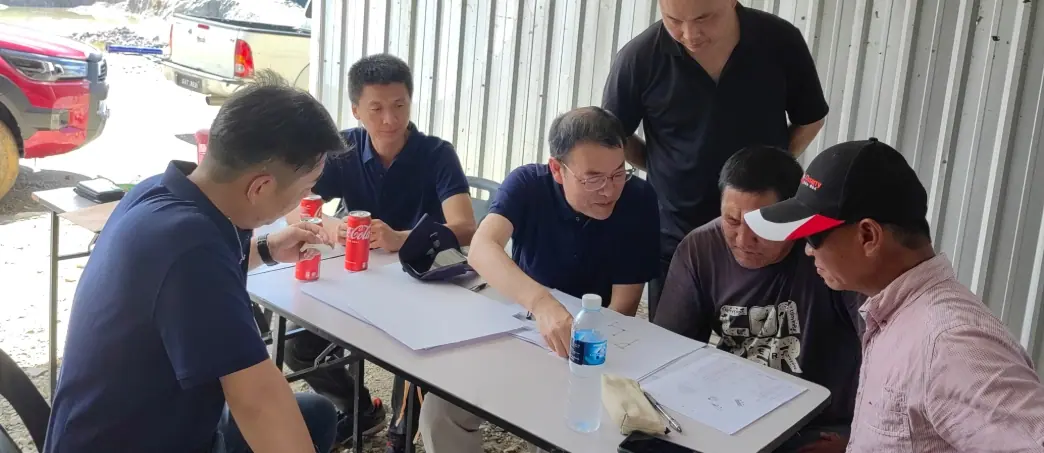

Trusted by Fortune 500 partners across global job sites

Mobile crusher plant is a smart choice for quarry crushing and construction waste recycling in Indonesia. Easy to move and quick to set up, it works well on city projects or remote sites. With local service, fast delivery, and flexible options, we help you crush better and faster. Let’s find the best mobile crushing solution for your needs.

See How Our Mobile Crusher Plants Work Across Indonesia & Beyond

From road building in Medan to quarry crushing in other countries, our mobile crusher plants for sale are working smoothly on many job sites. Take a look at how real customers use our portable crusher machines to get the job done faster and easier.

for Crushing Mountain Stone in Kalimantan

APYE-4060 Crawler Jaw Crusher in Kalimantan

- Location: in Kalimantan, Indonesia

- Capacity: 30TPH

- Feeding Size: ≤320mm

- Output Size: ≤70mm

- Application: for Road base material production

- Configuration: Jaw Crusher, Belt Conveyor, Track + Motor Reducer, PLC Control Box, etc.

- Production Time: 45 working days

- Payment Term: 30% T/T in advance, 70% T/T after checking finished goods but before shipment.

- Warranty: 1 year, excluding wear parts.

for Crushing Granite in Sukabumi

4-in-1 Mobile Crusher Plant in West Java

- Location: in West Java, Indonesia

- Capacity: 100TPH

- Feeding Size: ≤630mm

- Output Size: 5-10-20-40mm

- Application: Produce Construction Aggregates in Road Projects

- Configuration: Cone Crusher and Screener, Jaw Crusher, Vibrating Feeder, PLC Control Box, etc.

- Customer Review: “I start the granite crusher plant easily with PLC control, adjust feeding remotely, and move it quickly between sites. Remote monitoring keeps downtime low.”

for Crushing Andesite in Medan

Portable Jaw Crusher Plant in Medan

- Location: in Medan, Indonesia

- Capacity: 30TPH

- Feeding Size: ≤340mm

- Output Size: ≤10mm

- Application: for Road Base Aggregates

- Configuration: Belt Aggregate Conveyor, Jaw Crusher, Mobile Chassis + Vibrating Feeder

- Customer Review: “This mobile jaw crushing plant runs smoothly and saves us a lot of transport costs. It’s good for road work in Medan—fast setup, reliable output, and easy to relocate.”

for Construction Waste Recycling in Colombia

3-in-1 Mobile Impact Crusher in Colombia

- Location: in Bogotá, Colombia

- Capacity: 150TPH

- Feeding Size: ≤500mm

- Output Size: 0–6–19–25–51mm

- Application: for Demolition Waste from the subway

- Configuration: Belt Aggregate Conveyor, Impact Crusher, Mobile Chassis + Vibrating Feeder

- Customer Review: “I can crush and screen demolition waste directly on-site with one machine. The mobility, dust control, and remote feeding make it perfect for tight urban jobs like our Bogotá subway project.”

Now, let’s take a closer look at our different types of mobile type crusher plants—designed to meet various crushing needs on sites across Indonesia and worldwide.

Tire Mobile Crusher Plant – Fast and Cost-Effective Crushing on the Move

Looking for portable crusher plants that are easy to move between job sites? Our tire-mounted crushing plants are perfect for road work, quarries, and small to mid-size projects across Indonesia. Quick to install and simple to operate, they help you start crushing fast—with less hassle and lower cost. Let’s see wheel type mobile crushing plants for sale.

Mobile Jaw Crusher for Sale – For Big Stone Crushing on Indonesian Sites

Need to crush big stones on your site in Indonesia? Our tire-type portable jaw crushers for sale are perfect for breaking down hard rock into road base or smaller sizes. The portable jaw crusher for sale is ideal for quarry sites in Java, Kalimantan, and more—easy to move, fast to install, and simple to operate.

Wheel-Type Mini Mobile Jaw Crusher Introduction

- Stone Crusher Capacity: 5-60 T/H

- Maximum feeding size: ≤340mm

- Adjustable discharging size: 20-100mm

- Application: suitable for small to medium-scale projects

- Configuration: Jaw crusher, diesel type engine, and feeding hopper

Key Features

- Easy to Move: Wheel-mounted design for quick transport between sites.

- Diesel Engine Driven: No external power needed—ideal for remote areas.

- Versatile Application: Crushes concrete waste, limestone, granite, and more.

- Adjustable Output: Ideal for road base, paving, or house aggregate.

- Efficient: Fits small to medium projects like residential sites, small road.

2-in-1 Mobile Jaw Crusher Plant

- Stone Crusher Capacity: 50-450 T/H

- Maximum feeding size: ≤720mm

- Adjustable discharging size: 20-200mm

- Raw Materials: andesites, limestone, granite, etc.

- Configuration: Jaw crusher, feeder and belt conveyor

Key Features

- Integrated Design: Combines jaw crusher and feeder in a compact design.

- Versatile Material Handling: Suitable for hard stones like limestone, granite.

- Flexible Output: Flexible discharge size to meet different project needs.

- Easy Mobility: Wheel-mounted for easy transport between job sites.

- Low Maintenance: Simple structure/low maintenance/stable performance.

3-in-1 Mobile Jaw Crushers Introduction

- Stone Crusher Capacity: 30-180 T/H

- Maximum feeding size: ≤480mm

- Adjustable discharging size: 30-150mm

- Raw Materials: andesites, limestone, granite, etc.

- Configuration: Jaw crusher, Vibration Screen, feeder and belt conveyor

Key Features

- All-in-One Design: Crushing, screening, and feeding in one unit for lower cost.

- Smart Control: One-touch start with PLC or buttons—easy to operate.

- IoT Remote Monitoring: reduces downtime and improves maintenance.

- Easy to Move: 3-axle chassis for quick relocation between job sites.

- Energy Saving: Lower power use with efficient motor up to 30%.

Tire Type Mobile Cone Crushers – Stable Output for Hard Stone

Working with hard stone like basalt or andesite? The portable cone crusher for sale delivers consistent, fine output—perfect for concrete plants, road projects, and mining jobs in places like Sumatra or Sulawesi. The mobile type cone crusher runs smoothly and adapts well to long-term operations.

Single Tire Type Mobile Cone Crusher Introduction

- Stone Crusher Capacity: 110-590 T/H

- Maximum feeding size: ≤250mm

- Adjustable discharging size: 5-100mm

- Application: Basalt, Andesite, Granite Crushing

- Configuration: Cone Crusher, Convey Belt(Vibration screen Optional)

Key Features

- Mobile Flexibility: Easily moves, ideal for scattered projects across islands.

- Medium & Fine Crushing: For producing quality aggregates from hard stone.

- Excellent Shaping: Good shaping performance for concrete and asphalt use.

- Belt Conveyor Feeding: Heavy-duty belt feeder ensures stable material flow.

- Tropical Adaptability: Reliable in hot, humid, and rainy environments.

2-in-1 Tire Type Mobile Cone Crusher Plant

- Stone Crusher Capacity: 50-590 T/H

- Maximum feeding size: ≤250mm

- Adjustable discharging size: 5-100mm

- Raw Materials: andesites, limestone, granite, etc.

- Configuration: Cone Crusher, Convey Belt, Feeder, and Vibration Screen

Key Features

- Integrated Design: Combines jaw crusher and feeder in a compact design.

- Versatile Material Handling: Suitable for hard stones like limestone, granite.

- Flexible Output: Flexible discharge size to meet different project needs.

- Easy Mobility: Wheel-mounted for easy transport between job sites.

- Low Maintenance: Simple structure/low maintenance/stable performance.

Mobile Impact Crushers – Ideal for Road Base & Recycling

Need clean, shaped material for road base or reuse? This tire type mobile impact crusher for sale is a smart choice for crushing soft to medium materials like concrete or limestone—great for urban recycling jobs in Surabaya or road upgrades in Medan. The mobile crushers and screeners give you better shape and low dust.

2-in-1 Tire Type Mobile Impact Crusher Plants Introduction

- Stone Crusher Capacity: 60-350 T/H

- Maximum feeding size: ≤300mm

- Adjustable discharging size: 5-180mm

- Application: Soft to medium materials like concrete or limestone

- Configuration: Impact Crusher, Vibrating screen, PLC control box, etc.

Key Features of Portable Impact Crushers

- 2-in-1 Design: Crushing and screening in one unit, efficient and compact.

- Heavy-Duty Rotor: Strong impact, big reduction ratio, better shape.

- Easy to Move: Tire-mounted for quick transfer between different sites.

- Smart Control: PLC system ensures simple and stable operation.

- Quick Setup: Fast installation, ideal for shifting projects in Indonesia.

3-in-1 Tire Type Mobile Impact Crusher Introduction

- Stone Crusher Capacity: 50-350 T/H

- Maximum feeding size: ≤600mm

- Adjustable discharging size: 5-180mm

- Application: Great for urban waste recycling jobs

- Configuration: Vibrating feeder, Impact crusher, and Vibrating screening

Key Features

- All-in-One Design: Feeding, crushing, and screening in one mobile unit.

- Smart Control System: PLC + buttons with IoT monitoring for easy use.

- Intelligent Feeding: Remote-controlled feeder with adjustable speed.

- Strong Impact Crusher: Heavy rotor, big ratio, good shape, two-stage ready.

- Eco & Mobile Ready: 3-axle chassis, dust-proof, low energy, easy move.

Tire 4-in-1 Mobile Crusher Plant – One Machine, Full Process

Want one compact unit to handle everything on-site? Our wheel type 4-in-1 mobile crushing plant for sale integrates feeding, crushing, screening, and conveying—saving time and transport costs. The mobile crusher and screening plant is perfect for fast-moving jobs across islands like Lombok, Bali, or even Papua.

4-in-1 Mobile Crusher Plant for Sale Introduction

- Stone Crusher Capacity: 50-350 T/H

- Maximum feeding size: ≤625mm

- Adjustable discharging size(mm): 0-5-10-20-40,etc.

- Application: Great for urban waste recycling jobs

- Configuration: Jaw crusher + Adjustable Crusher(cone crusher/impact crusher/fine jaw crusher)

Key Features

- 4-in-1 Design: Crushing, screening, feeding, and transfer – cut cost by 30%.

- Smart Control: PLC + IoT remote control, supports 2G/3G/4G/WiFi networks.

- Stable Move: 3-axle + sled base ensures quick shift and firm setup on soft ground.

- Crusher Switchable: Fits impact, cone, or fine jaw – great for andesite.

- Low Maintenance: Elastic support + auto iron remover – cut downtime by 40%.

Tire Mobile VSI Crusher Plant – For Quality Sand Production

Need to produce high-quality sand on-site in Indonesia? Our VSI crusher mobile plant turns hard stone like andesite or river pebble into fine, uniform sand—ideal for concrete mixing, building blocks, and infrastructure in Java, Sulawesi, and coastal areas. Compact, efficient, and ready to move where your project goes.

Mobile Type Sand Making Machine Introduction

- Stone Crusher Capacity: 60-480 T/H

- Maximum feeding size: ≤65mm

- Adjustable discharging size(mm): 0-4.75

- Application: River pebble, limestone, manufactured sand projects

- Configuration: Vibrating screen, VSI Crusher, PLC control box, etc.

Key Features of Mobile Screen Crusher VSI

- Precise Sand Control: Produces clean, graded sand for concrete and asphalt.

- Mobile & Compact: Tire-mounted design, ideal for coastal and remote job sites.

- Adjustable Output: 0–4.75mm discharge size fits ready-mix and precast needs.

- Smart Operation: PLC system with touch or button mode – easy for local teams.

- Low Dust, Low Cost: Enclosed system reduces dust, saves up to 30% energy.

Mobile Screening Plant – Clean Separation for Any Material

Already have crushed materials and need accurate sizing? This standalone portable screening plant helps you sort aggregates by size—quickly and cleanly. Widely used in aggregate yards, quarry stockpiles, and construction sites across Indonesia. Easy to combine with other mobile crushers for sale for closed-loop operations.

Normal Mobile Screening Plant Introduction

- Stone Crusher Capacity: 65-700 T/H

- Maximum feeding size: ≤200mm

- Amplitude: 8-12mm

- Application: Sand, gravel, crushed stone, small to mid-size screening jobs

- Configuration: Vibrating screen, Conveyor belt, PLC control box, etc.

Key Features

- Wide Capacity: Handles high efficiency, fits large and small quarry needs.

- Clean & Precise Screening: Greatly improves output quality for concrete use.

- Fast Transfer & Setup: Tire-mounted, perfect for projects across Java.

- Smart Control: PLC with local language interface, easy for on-site teams.

- Energy Saving: Low power use, ideal for long-shift screening in rural areas.

Heavy Duty Mobile Screening Plant Introduction

- Stone Crusher Capacity: 100-400 T/H

- Maximum feeding size: ≤300mm

- Amplitude: 8-12mm

- Application: Heavy rock, demolition waste, and quarry pre-screening

- Configuration: Vibrating screen, Conveyor belt, PLC control box, etc.

Key Features of Portable Screen Plants

- Built for Tough Jobs: Handles large, wet, or abrasive material up to 300mm.

- Stable & Strong Structure: Heavy-duty frame resists shock on rough terrains.

- Efficient Double Deck Screen: for coal, limestone, and construction waste.

- Quick Deployment: Easy move between remote sites without foundation.

- Low Maintenance: Dust-sealed bearings/ wear-resistant screens extend life.

Crawler Mobile Crusher Plant – Built for Rough Terrains and Remote Sites

Working in muddy, hilly, or remote areas in Indonesia? Crawler-type mobile crusher Indonesia is made for tough jobs. With powerful tracks, the tracked crusher mobile moves smoothly on challenging sites—from mining in Kalimantan to road building in remote Papua. Fast to deploy, fuel-efficient, and highly stable, the crawler type stone crusher plant is ideal for heavy-duty crushing work.

Crawler Jaw Crusher – First Choice for Tough Primary Crushing

Working in a remote quarry or mining site in Indonesia? The crawler mobile jaw crusher machine is built for strong, stable primary crushing—even on muddy or uneven ground. Perfect for hard rock in Kalimantan or remote projects in Papua. It moves on tracks, needs no foundation, and gets to work fast.

Track Mounted Jaw Crusher Introduction

- Stone Crusher Capacity: 20-50 T/H

- Maximum feeding size: ≤380mm

- Adjustable discharging size: 20-50mm

- Application: for road construction project, building project etc.

- Configuration: Jaw crusher, diesel engine, and feeding hopper

Key Features of Track Crusher Jaw

- Compact: Crawler chassis + diesel engine, moves easily in remote areas.

- Fuel-Efficiency: Diesel-driven, no grid needed – ideal for rural areas.

- Versatile for Small Jobs: Handles waste, soft and hard stone with ease.

- Easy Operation:Simple controls, low upkeep, fits small contractor teams.

- Direct Use Aggregates: Output ideal for sub-base, backfill, and on-site reuse.

2-in-1 Crawler Jaw Crusher Mobile

- Stone Crusher Capacity: 80-450 T/H

- Maximum feeding size: ≤700mm

- Adjustable discharging size: 60-250mm

- Raw Materials: andesites, limestone, granite, etc.

- Configuration: Jaw crusher, feeder and belt conveyor

Key Features of Tracked Jaw Crusher

- 2-in-1 Crushing: Feeding + crushing, ideal for big-stone primary processing.

- Hydraulic Control: Adjust output size easily to meet project demands.

- High-Efficiency Jaw: C-series jaw with large hopper and pre-screen system.

- Reinforced Frame: Heavy-duty Q355B steel ensures strength and long life.

- Crawler Mobility: Stable on rough ground, great for remote Indonesian sites.

Crawler Cone Crusher – High-Performance for Hard Stone

Need stable fine crushing in tough environments? This tracked cone crusher handles hard stone like basalt or granite with ease. These track mounted crushers are great for mining or aggregate production in Sumatra, Aceh, or rugged island terrains and consistent output, low wear, and strong mobility.

Crawler Cone Crusher Introduction

- Stone Crusher Capacity: 100-310 T/H

- Maximum feeding size: ≤250mm

- Adjustable discharging size(mm): 3-60

- Application: for granite, basalt, andesite—secondary crushing in quarry

- Configuration: Vibrating screen, Cone Crusher, PLC control box, etc.

Key Features

- For Hard Rock: Laminating cone crusher handles tough stone with ease.

- Stable Feeding: High-torque feeder ensures smooth, even material flow.

- High Efficiency: Big output, low wear — great for heavy-duty use.

- Smart Control: PLC with LCD, IoT, and remote speed adjustment.

- Durable Design: Dustproof control box, soft-start motor, overload safe.

Crawler Impact Crusher – Flexible Crushing for Recycling & Road Jobs

Doing road upgrades or recycling in mixed ground conditions? Crawler impact crushers are ideal for soft to medium materials, such as concrete, limestone, or brick. The tracked mobile crusher is widely used in city projects in Java and flexible enough for inland sites—easy to move, with excellent shaping and low dust.

Crawler Impact Crusher Introduction

- Stone Crusher Capacity: 80-300 T/H

- Maximum feeding size: ≤600mm

- Adjustable discharging size(mm): 5-200

- Application: for waste, soft rock, and primary or secondary crushing

- Configuration: Vibrating screen, Impact Crusher, Vibration Feeder, etc.

Key Features

- Dual-Stage Crushing: Handles both primary and secondary jobs in one unit.

- Good Grain Shape: Impact design ensures clean, well-graded final aggregates.

- Smart Control: PLC + LCD screen, IoT support, remote feeding adjustment.

- Hydraulic Assistance: Easy access and control with hydraulic-assisted functions.

- Iron Removal & Spray: Built-in iron remover and spray system for dust control.

Crawler VSI Crusher – Mobile Sand Making for Remote Areas

Need to produce fine sand in hard-to-reach project sites? Our crawler-type VSI crusher turns andesite, river stone, or tailings into high-quality manufactured sand. Built on tracks, it works well in remote or narrow areas—perfect for coastal towns, mining camps, or inner-island jobs in Indonesia.

Crawler Mobile Vertical Shaft Crusher Introduction

- Stone Crusher Capacity: 70-450 T/H

- Maximum feeding size: ≤80mm

- Adjustable discharging size(mm): 0-4.75

- Application: Used for sand making or shaping after secondary crushing

- Configuration: VSI Crusher, Belt Conveyor, Vibrating screen(Optional),etc.

Key Features

- Shaping & Sand Making: Perfect for final-stage shaping or producing sand.

- High-Output VSI Crusher: New impeller design ensures high capacity and low wear.

- Compact & Mobile: Crawler-mounted, easy to deploy across diverse job sites.

- Low Energy Use: Efficient crushing reduces energy cost by up to 30%.

- Good Grain Shape: Produces clean, uniform sand for concrete/asphalt plant.

Crawler Mobile Screening Plant – Precise Grading for Every Site

Need to sort materials on rugged ground or wet conditions? This tracked screening plant moves easily across muddy or uneven terrain—no foundation needed. Whether you’re screening crushed rock in Kalimantan or recycled aggregates in Surabaya, it ensures clean, consistent sizing wherever you need it.

Normal Crawler Mobile Screening Plant Introduction

- Stone Crusher Capacity: 120-450 T/H

- Maximum feeding size: ≤200mm

- Adjustable discharging size: 0-10-20-30,etc.

- Application: Sand, gravel, stone, and recycled waste — final screening

- Configuration: Vibrating screen, Belt Conveyor, PLC control box, etc.

Key Features

- Precision Screening: Accurate sizing for clean, market-ready aggregates.

- Auto Folding Belt: Fast setup with built-in folding conveyors.

- Hydraulic Assist: Easy screen adjustment and maintenance with its support.

- Flexible Mobility: Crawler chassis enables fast shift on all terrains.

- Durable Build: Long-lasting components for tough tropical conditions.

Heavy Duty Crawler Mobile Screening Plant Introduction

- Stone Crusher Capacity: 300-400 T/H

- Maximum feeding size: ≤500mm

- Adjustable discharging size: 0-10-20-30,etc.

- Raw Materials: Soil-rock separation, demolition waste, large pre-screening

- Configuration: Vibrating screen, Belt Conveyor, PLC control box, etc.

Key Features

- For Tough Materials: Handles big rocks, wet clay with heavy-duty screen.

- Wide Belt Conveyor: 1.2m pattern belt conveyor ensures smooth flow.

- Heavy-Duty Frame: Reinforced body for impact and continuous work.

- Primary Screening Use: Great for rough separation before crushing.

- Stable & Reliable: Strong frame delivers steady output, less downtime.

Mobile Crushing and Screening Solutions

Need a reliable solution for your crushing and screening tasks? A mobile crushing and screening plant is the key. It’s flexible for projects of all sizes, handling different capacities and materials with ease. This solution boosts efficiency, reduces downtime, and ensures high-quality results. Let’s explore the best options about mobile crusher plant for your project needs.

150TPH Stone Crusher Plant for Crushing Quartz

![]() Raw Material: Quartz

Raw Material: Quartz

![]() Feeding Size: 400mm

Feeding Size: 400mm

![]() Final Product Sizes:0-3mm quartz sand

Final Product Sizes:0-3mm quartz sand

![]() Application: for making glass and ceramics

Application: for making glass and ceramics

Configuration: mobile jaw-type stone crusher plant, mobile cone-type stone crusher plant, and sand making machine

Mobile Crusher 200 TPH-250 TPH for Crushing Granite

![]() Raw Material: Granite

Raw Material: Granite

![]() Feeding Size: 600mm

Feeding Size: 600mm

![]() Final Product Sizes: 0-24mm aggregate

Final Product Sizes: 0-24mm aggregate

![]() Application: for making concrete, asphalt, and road paving material

Application: for making concrete, asphalt, and road paving material

Configuration: tracked jaw crusher plant and mobile cone-type stone crusher plant.

How to Choose a Portable Crushing Plant in Indonesia

With Indonesia’s diverse terrain, scattered islands, and growing demand for aggregates, choosing the right portable crushing plants is crucial. Whether you’re working on road projects in Java or quarrying in Kalimantan, the right setup can save time, cost, and labor. Here’s a quick guide to help you decide:

| Customer Pain Point | Key Consideration | What to Look For | Why It Matters in Indonesia |

|---|---|---|---|

| 🛣️ Difficult terrain, frequent transfers | Mobility & Transfer Speed | Tire type for roads, Crawler type for remote/off-road | Indonesia has scattered islands and diverse terrains — fast relocation is critical |

| 🪨 Various material hardness | Crusher Type & Flexibility | Jaw for primary, Cone for hard rock, Impact for shaping | From soft limestone in Java to hard andesite in Kalimantan — matching material is key |

| 🏗️ Multiple project types | Configuration Combinations | 2-in-1, 3-in-1, or 4-in-1 setups (feeder + crusher + screen) | Helps reduce equipment quantity and saves costs for multi-phase jobs |

| ⚡ Limited access to power | Power Supply & Independence | Diesel-driven systems, hybrid options | Many remote sites lack reliable electricity — diesel gives flexibility |

| 💨 Dust, noise & pollution control | Environmental Compliance | Enclosed belts, spray systems, negative-pressure dust collectors | Strict local regulations in urban areas like Jakarta, Surabaya — cleaner operation wins bids |

| ⏱️ Need for quick startup | Setup Time & User-Friendliness | One-touch PLC, pre-assembled units, auto-folding belts | Time = money — faster setup means earlier production |

| 💰 Budget control | Energy Use & Maintenance | Fuel-efficient engines, low wear parts, remote monitoring (IoT) | Cuts fuel and repair costs — key for long-term operations in provinces |

Mobile Crusher Plant Price in Indonesia: What to Know Before Buying

If you’re considering a mobile crusher plant for your project in Indonesia, chances are one of your first questions is: “How much does a mobile crusher cost?” The real answer is: It depends on what you actually need. Let’s break it down clearly, so you don’t waste time or money.

Why There’s No Fixed Mobile Crusher Price

- The type of mobile crushers you need (jaw, impact, cone, VSI)

- The number of crushing stages (2-in-1, 3-in-1, or more)

- Your required capacity and output sizes

- Whether it’s wheeled or track mounted crusher plant

- Whether it includes screening, conveying, or power system

- Logistics, installation, and after-sales service — especially important in Indonesia

🔍 Tip: Asking “how much?” without explaining your needs won’t get you a useful answer.

What Project Type Are You Doing?

| Project | Crushing Needs | Suggested Mobile Setup |

|---|---|---|

| Road base layer | Coarse + medium crushing | Jaw + cone or impact |

| Asphalt aggregate | Shape control is key | Jaw + impact + screen |

| Sand production | Fine crushing, shaping | Add VSI or vertical shaft impactor |

| Remote mining | No power, hard terrain | Diesel-powered crawler unit |

⚠️ Crawler mobile crushers for sale are great for off-road areas — but they cost more. Don’t choose one unless truly needed.

What Affects Price the Most?

- Crushing stage configuration: A simple jaw crusher mobile is cheaper than a multi-stage system.

- Capacity requirements: A mobile crushing unit that handles 200 tons/hour costs more than one for 50 tons/hour.

- Mobility type: Mobile Crawler crusher units are more expensive than wheeled ones.

- Automation level: Fully automatic mobile crusher plants come with higher cost, but reduce labor.

🧠 Good mobile crushing plant suppliers won’t just sell you the highest configuration — they’ll match your needs with the most efficient setup.

🇮🇩 Special Note for Indonesian Buyers

- Shipping to your site (Java, Sumatra, Kalimantan, Sulawesi, etc.)

- Import taxes and permits (depending on customs clearance support)

- Availability of local technicians and spare parts about mobile crusher china.

- Choosing a mobile crushing plant manufacturer that already has experience in Indonesia saves time and cost in the long run.

So, What Should You Do Before Asking for a Price?

- Type and size of raw material (e.g., limestone, granite, river stone)

- Desired output sizes (e.g., 0–5mm, 5–10mm, 10–20mm)

- Required capacity (tons/hour)

- Project location and power availability

- Preferred mobility (wheeled or crawler)

🎯 With this info, mobile crushing plant manufacturers can give you an optimized plan — not just a price tag.

Mobile crushing plant price is important — but a wrong machine wastes more money than an expensive one. Instead of asking “what’s the cheapest?”, ask: “What’s the best portable crusher for sale for my material, my capacity, and my project site?” We’re here to help you get the harga stone crusher mobile.

Technical Advantages of Our Mobile Crusher Plants for Indonesian Projects

In Indonesia’s diverse and challenging environments, efficient and reliable crushing solutions are essential. Our 3-in-1 and 4-in-1 mobile crusher plants offer integrated smart control, flexible configurations, strong mobility, and eco-friendly features—delivering high productivity and low costs. Let’s learn the advanced advantages of mobile crusher plants.

Integrated Smart Control

One-touch startup with PLC touchscreen and manual buttons, plus IoT remote monitoring ensures stable, efficient operation even in remote Indonesian sites.

Flexible & Modular Design

Easily switch secondary crushers (impact, VSI, fine jaw) to adapt quickly to different materials and project requirements, maximizing versatility.

Stable & Fast Mobility

Three-axle chassis with sled base offers rapid relocation and excellent ground stability, ideal for Indonesia’s varied terrain and island transfers.

Durable & Protected Conveyors

Anti-wear rollers, buffer beds, and double sealing minimize belt damage and dust pollution, lowering maintenance and extending service life.

Advanced Dust Suppression

Comprehensive dust control system—including fog cannons, telescopic covers, and negative pressure filtration—meets environmental regulations.

Energy Efficient Operation

Low-power motors and optimized system design reduce energy consumption by up to 30%, lowering operational costs while supporting green initiatives.

How Does a Mobile Crushing Plant Work? (From My Point of View)

Hi there! I’m a mobile crushing plant, and no, I don’t just sit there — I crush rocks, travel between jobsites, and help build roads, bridges, and cities all across Indonesia. Want to know how I do all that? Let me walk you through my workday.

I Arrive Fully Assembled and Ready to Work

No concrete foundation. No long installation. Once I’m unloaded from the truck, I unfold my conveyors, adjust my tracks or tires, and start working within hours. Whether I’m in a limestone quarry in East Java, a recycling yard in Medan, or a road project in Sulawesi, setup is fast and simple.

Feeding Starts – My Hopper Gets to Work

Raw materials like rocks, concrete waste, or river stone are fed into my vibrating feeder. This part controls the flow and sends material smoothly into my primary crusher.

Crushing Happens – My Main Crusher Takes Over

This is my core job. Depending on the model, I might use: A jaw crusher for breaking large, hard stone, A cone crusher for medium to hard materials, An impact crusher for softer or recycled materials Or a VSI crusher for shaping and making sand. Once inside, I apply force and pressure to reduce material size to whatever the project needs — like 0–5mm, 10–20mm, or 20–40mm.

Screening – I Separate by Size

After crushing, the material goes to my vibrating screen. Here, I sort out different sizes: Fine dust and sand, Medium-size gravel and Oversized particles that may return for re-crushing. In most cases, my screened output is ready to be used directly in road base, concrete mixing plant, or asphalt production.

Circulation – I Recycle Inside Myself

If material is too big or needs more shaping, it loops back to the crusher mobile through my return belt system. This ensures higher quality and better control over output size.

Control – My Brain Keeps Me Running

My operations are managed by a PLC control box, often with touchscreen + button panel. In some models, my feeding and output can be adjusted in real-time. With IoT or remote control, operators can even monitor me from a distance.

🎥 Want to see how it all works together? Watch our 3D display of the Crawler Type Mobile Crushing Production Line below

Mobile Crusher Plant Trends in Indonesia 2025+: Smarter, Greener, Faster

With rising investment in infrastructure and minerals, mobile crusher plants are quickly becoming the go-to solution for on-site aggregate processing. In 2025 and beyond, the market is moving toward smarter, cleaner, and more flexible crushing systems. This overview highlights key trends, real growth data, and what truly matters to Indonesian customers.

Market Size & Growth

- Asia‑Pacific leads the mobile crushing machine sector, valued at roughly USD 2.49 billion in 2025, up from USD 2.29 b in 2024, growing at ~8.6% CAGR through 2034.

- Indonesia, as part of APAC, is benefiting from this boom—largely driven by road, infrastructure, and mining investments (including nickel and other minerals)

- Global mobile crushers & screeners market reached ~USD 3.99 b in 2024, projected to hit USD 4.17 b in 2025 and expand at ~5.1% CAGR to USD 5.35 b by 2030.

- Asia‑Pacific mobile crushing stations (incl. Indonesia) were valued at USD 1.65 b in 2024, with expected 6.8% CAGR through 2033.

Indonesia-Specific Drivers

- Mining & Nickel Boom: Indonesia produced 1.6 million tonnes of nickel ore in 2023, fueling the adoption of portable crushers for remote mining sites. Strong FDI in base metals/mining reached ~USD 11 b in 2022, with continued momentum into 2023–26.

- Infrastructure Push: National construction sector grew ~4.85% in 2023, underpinned by transport & storage (+13.96%). Indonesian highway/rail projects drive higher installation of on-site mobile crushers to cut transportation costs.

Technological & Regulatory Trends

- Rapid shift toward IoT-enabled smart crushers: advanced sensors, remote diagnostics, automation—mirroring broader APAC trends.

- Hybrid and electric-powered portable concrete crushers gain traction, improving fuel efficiency and emissions compliance.

- Modular designs for easy transport ++ regulatory-driven engineering, adapting to local Indonesian emissions and fuel-efficiency standards (e.g., aligning with APAC’s standards requiring ~15% improvement since 2020).

Key Industry Trends in Indonesia

- Mobile crusher for sale favored for in-pit crushing in nickel/mining sites.

- Hybrid/electric mobile crusher stations become standard in new procurements.

- Digitalization & IoT adoption rising: predictive maintenance, remote control.

- Modular/regulation‑compliant designs to meet fuel and emission standards.

- After-sales/spare parts boom: APAC shipments ~3,000 units/year, with parts & services worth ~USD 600 m globally.

Maintenance and Overhaul Precautions for Mobile Crusher Plant

How to maintain the mobile crushing plant? Mobile crusher plants are essential for construction and mining projects, offering flexibility and efficiency. Regular maintenance is crucial to ensure smooth operation and extend equipment lifespan. This guide outlines key maintenance precautions to help minimize downtime and keep your China mobile crusher running reliably.

Lubrication Requirements

Forced Lubrication: Use forced lubrication for large crusher mobile.

Monitor Parameters: Check oil temperature, pressure, and flow rate.

Tighten Fasteners: Regularly tighten loose fasteners.

Noise and Vibration Monitoring

Monitor Vibration: Watch for unusual vibrations.

Stop for Inspection: Stop the machine if issues occur.

Restart Correctly: Follow the startup sequence after repairs.

Product Quality and Yield

Monitor Yield: Track mobile crusher yield for abnormalities.

Inspect for Blockages: Address blockages promptly.

Check Screen Surface: Ensure the screen surface is not damaged.

Scheduled Repairs

Assess Condition: Evaluate equipment for necessary repairs.

Prevent Breakdowns: Regular maintenance reduces unexpected failures.

Conduct Inspections: Regularly inspect for wear and tear.

Maintenance Planning

Use Spare Machines: Use spare units for maintenance to minimize downtime.

Improve Utilization: Implement strategies to enhance equipment use.

Review Plans Regularly: Adjust maintenance plans as needed.

These practices help maintain the performance and longevity of your mobile crusher plant, ensuring efficient operations and reducing downtime.

Mobile Crusher Plant Workshop Overview

For more than 40 years of hard work, we have a large-scale production plant of 60,000 square meters. We have professional core production technology for rock crushers and have a complete factory system. The following picture is taken in our workshop of mobile crushing and screening plants.

What You Get from Our Mobile Crushing Services in Indonesia

As one of the leading mobile crusher plant manufacturers in Indonesia, we go beyond supplying machines — we deliver end-to-end project support to help you build faster, smarter, and safer. Here’s how we support your success:

Local Branch & Warehouses

6+ warehouses across Indonesia ensure spare parts arrive within 1–3 days, reducing wait time.

Full Project Planning Support

We help reduce project duration by 15–30% through expert layout design, budgeting, and site planning.

Customized Solution Matching

1-on-1 technical support to align equipment configuration with actual site and capacity needs.

ROI & Profitability Analysis

Data-driven investment models help lower financial risk by up to 40%, making decisions safer.

Efficient Information Support

Detailed drawings and clear documentation help reduce installation time and labor cost by 20–25%.

Strict Quality Inspection

100% of mobile crusher machines undergo no-load testing, cutting failure-related downtime by 30–50%.

Safe & Fast Transport Design

Reinforced packaging and smart container planning reduce transport damage risk by over 80%.

Training & Installation Services

Online and on-site support minimize errors and cut labor costs by 20%, speeding up startup.

24h After-Sales & Follow-Up

24/7 troubleshooting and regular check-ins improve uptime and extend equipment life by 25%.

Ready to Maximize Your Crushing Efficiency?

Our mobile crusher plants deliver proven performance, flexibility, and cost savings tailored to your project needs. Contact us today for a detailed quote and expert consultation. Let’s work together to optimize your operations, reduce downtime, and boost your profits with solutions designed for Indonesia’s toughest conditions.