High-efficient impact crusher, stable output — Handles various materials, runs smoothly nonstop.

Uniform particle shape, 95% pass rate — Ideal for construction, roads, bridges, and aggregates.

Durable & energy-saving, 20%-30% less power — Wear-resistant, easy to maintain, lower costs.

Local service, 48-hour response — Fast installation and support across Indonesia.

Worried about fast wear, tough maintenance, or poor-quality aggregates? Our impact crushers in Indonesia are built to endure tough conditions, run smoothly with minimal upkeep, and produce consistent, high-quality aggregates for roads and local construction projects. Local support and customizable setups keep your operations efficient and stress-free.

- 【Feeding Size】: ≤1300mm

- 【Output Size】: 5-200 mm

- 【Impact Crusher Capacity】: 20t/h-550t/h

- 【Types】: APF-H/APF-V/APF Series

- 【Crushing Method】: High-speed hammer impact + impact plate collision

- 【Particle Size】: Cubic-shaped, low needle content, well-graded

- 【Crushing Materials】: Limestone, coal gangue, construction waste, concrete

- 【Application】: Road and bridge aggregates, concrete production, cement raw materials, construction waste recycling

With stable performance and high-quality output, our jual impact crusher for sale meets the diverse aggregate and construction material needs in Indonesia. Next, we will provide a detailed introduction to different types of impact crushers to help you choose the most suitable crushing equipment.

What Are the Different Types of Impact Crushers in Indonesia?

In Indonesia, with the rapid growth of road construction, bridge projects, and concrete aggregate demand, efficient and durable crushing equipment has become essential. They mainly come in three impact crusher types: standard (APF), high-capacity (APF-V), and high-performance (APF-H). Our impact crusher delivers reliable capacity and superior output, perfect for limestone, cement aggregates, and construction waste. Learn how three types of impact crushers can meet your specific needs.

APF-H Series European type Hydraulic Impact Crushers for sale in Indonesia

In Indonesia’s high-end aggregate market, equipment must deliver high output, easy maintenance, and excellent particle shape. The European hydraulic impact crusher offers a hydraulic opening system and three-chamber crushing, replacing traditional two-stage crushing. It handles large stones and produces high-quality cubic aggregates.

-

- European Type Hydraulic Impact Crusher

- Max. Feeding Size: ≤1300 mm

- Finished Products Size: 5~200 mm

- Capacity: 70-900 t/h, Customizable

- Particle Shape: Adjustable, cubic particles, fewer flakes

- Processed Materials: Limestone, concrete aggregates, hard ores

- Application: Hydraulic opening and adjustment, easy maintenance, replaces jaw + impact crushing, saving space and investment, three-chamber crushing

APF-V Series Impact Crushers for Sale in Indonesia

With rapid growth in Indonesia’s road and bridge construction, the demand for high-quality, high-capacity aggregates is rising. The APF-V series impact crusher features a three-chamber design with rear chamber leveling, ensuring uniform particle size and high output. It is the top choice for large-scale aggregate plants and continuous production projects.

-

- APF-V Series Impact Crusher

- Max. Feeding Size: ≤700 mm

- Finished Products Size: 5~200 mm

- Capacity: 20-500 t/h, Customizable

- Particle Shape: Uniform output, high fine particle ratio, good shape

- Processed Materials: Limestone, medium-hard ores, construction waste

- Application: Three impact chambers with a rear chamber for uniform output, delivering high capacity for road, bridge, and aggregate projects.

APF Series Impact Crushers for Sale in Indonesia

The horizontal shaft impact crusher for sale is built for efficient and reliable crushing. They handle various materials with high crushing ratios and adjustable output sizes. Designed for durability, these crushers provide long-lasting performance and are an excellent choice for improving your production efficiency.

-

- APF Series Impact Crusher

- Max. Feeding Size: ≤700 mm

- Power: 90–400 kW

- Capacity: 100-550 t/h, Customizable

- Particle Shape: Cubic particles, fewer flaky shapes, uniform output

- Processed Materials: Limestone, ore, construction waste, concrete aggregates

- Application: Dual impact chambers for large feed materials, Stable capacity with good particle shape, Cost-effective, ideal for general aggregate production

These reversible impactor crusher types each excel in capacity, feed size, and particle shape, suiting diverse projects in Indonesia. To address scattered sites, transport challenges, and flexible production, next we introduce our mobile impact crusher solution, helping Indonesian construction sites produce aggregates efficiently and flexibly.

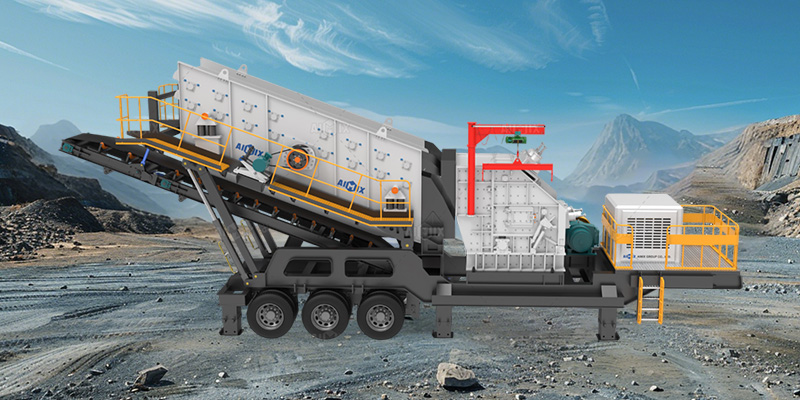

Mobile Impact Crushing Solutions in Indonesia

With the rapid growth of road, bridge, and urban construction in Indonesia, scattered sites, transport limitations, and production flexibility are key challenges for aggregate production. To meet these demands, we offer a range of mobile crusher plant solutions, suitable for various capacities and material types, ensuring efficient and adaptable production on-site.

2-in-1 Tire Type Portable Impact Crusher for Sale

- Capacity: 60-350 T/H

- Max Feeding Size: ≤300 mm

- Adjustable Discharging Size: 5-180 mm

- Crushing Materials: Soft to medium materials such as concrete

- Application: Best for scattered urban or construction sites

- Configuration: Impact crusher, vibrating screen, PLC control system

2-in-1 Tire Impact Crusher Advantages

- Saves 30% site area with compact design

- Mobility increased by 50% for easy relocation

- Heavy-duty rotor improves product shape, raising qualified output by 15%

- Efficient motors cut power by 20%; dust control reduces site dust by 60%

3-in-1 Tire Type Mobile Impact Crusher

- Capacity: 50-350 T/H

- Max Feeding Size: ≤600 mm

- Adjustable Discharging Size: 5-180 mm

- Crushing Materials: Urban waste recycling, construction debris, limestone

- Application: Highly integrated, ideal for waste and aggregate processing

- Configuration: Vibrating feeder, impact crusher, vibrating screening

3-in-1 Tire Impact Crusher Advantages

- Integrated design shortens production cycle by 20%

- Remote monitoring + PLC improves operational efficiency by 15-25%

- Fast mobility reduces relocation time by 40%

- Heavy-duty rotor produces fine material with 10-15% higher fine content

Crawler Mobile Impact Crusher Plant

- Capacity: 80-300 T/H

- Max Feeding Size: ≤600 mm

- Adjustable Discharging Size: 5-200 mm

- Crushing Materials: Construction waste, soft rock, primary or secondary crushing

- Application: Flexible for complex terrain and large-sized material

- Configuration: Impact crusher, vibrating screen, vibrating feeder, optional magnetic separator

Crawler Mobile Impact Crusher Advantages

- Integrated system lowers operating costs by 15%

- Flexible combination adapts to various conditions, improving utilization by 20%

- Chassis & skid support enhance stability and mobility by 30%

- PLC + remote monitoring ensures 25% more continuous production

These three mobile impact crushing solutions shine in different scenarios across Indonesia. From busy urban sites to challenging terrain and waste recycling, the right stone crusher plant is ready for you. Up next, explore the impact crusher specifications to find the perfect fit for your project.

Impact Crusher Technical Specifications

Choosing the right impact crusher is essential for efficient crushing performance. Below, we outline the key technical specifications for top models: APF-H, APF, APF-V impact crushers and mobile impact stone crushers. Check the specifications to find the best option for your specific needs.

Specifications of European Type Hydraulic Impact Crusher for Sale

| Model | Max feeding size L×W×H (mm) | Product particle size (mm) | Production capacity (t/h) | Power (kW) |

|---|---|---|---|---|

| APF-1010H | 400×400×500 | 20-100 | 70-150 | 90-132 |

| APF-1210H | 400×400×600 | 20-100 | 100-285 | 110-160 |

| APF-1214H | 400×400×600 | 20-100 | 150-400 | 160-200 |

| APF-1315H | 400×400×700 | 20-100 | 180-500 | 200-250 |

| APF-1317H | 400×400×700 | 20-100 | 200-600 | 200-315 |

| APF-1415H | 600×600×900 | 100-200 | 400-700 | 315-400 |

| APF-1620H | 600×600×1000 | 100-200 | 600-900 | 400-500 |

| *Note: Technical parameters are subject to change without prior notice. | ||||

Specifications of APF-V Series Impact Crushers for sale

| Model | Rotor diameter × length (mm) | Feed opening size (mm) | Feed particle size (Max,mm) | Production capacity (t) | Power (kW) | Weight (t) | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1007V | Φ1000×700 | 400×730 | 200 | 20-50 | 45-55 | 9.5 | 2400×1550×2660 |

| APF1010V | Φ1000×1050 | 400×1080 | 200 | 35-80 | 55-75 | 12.2 | 2400×2250×2620 |

| APF1210V | Φ1250×1050 | 570×1030 | 250 | 70-120 | 90-110 | 15 | 2690×2338×2890 |

| APF1214V | Φ1250×1400 | 570×1430 | 250 | 90-180 | 132-160 | 18.5 | 2690×2688×2890 |

| APF1315V | Φ1320×1500 | 625×1530 | 350 | 150-250 | 160-200 | 19.5 | 3096×3273×2667 |

| APF1320V | Φ1320×2000 | 625×2030 | 350 | 160-350 | 200-280 | 28 | 3096×3560×3185 |

| APF1415V | Φ1400×1500 | 800×1530 | 400 | 280-350 | 250-315 | 33 | 3220×3473×2960 |

| APF1520V | Φ1500×2000 | 1315×2040 | 500 | 300-500 | 315-400 | 43 | 3890×3564×3220 |

| With three counterattack chambers, the rear chamber has the function of leveling, the discharge particle sizeis uniform, the proportion of fine particle size is large, and the particle shape is good. *Note: Technical parameters are subject to change without prior notice. The output is calculated based on medium-hard materials and a bulk density of 1.6t/m3. The power is calculated based on medium-hard materials and an altitude below 1000 meters. The opening adjustment of the crushing chamber is divided into mechanical and hydraulic. |

|||||||

Specification of APF Series Impact Crushers for Sale

| Model | Rotor diameter × length (mm) | Feed opening size (mm) | Feed particle size (Max,mm) | Production capacity (t) | Power (kW) | Weight (t) | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1210 | Φ1200×1000 | 450×1060 | 350 | 100-160 | 90-110 | 17 | 2550×1940×2110 |

| APF1214 | Φ1200×1400 | 450×1440 | 400 | 130-200 | 132-160 | 22 | 2550×2340×2110 |

| APF1315 | Φ1300×1500 | 550×1530 | 450 | 180-320 | 160-200 | 29 | 2720×2460×2410 |

| APF1320 | Φ1300×2000 | 610×1900 | 500 | 230-400 | 200-250 | 38 | 2720×3060×2410 |

| APF1415 | Φ1400×1500 | 800×1530 | 600 | 280-450 | 250-315 | 40 | 3120×2650×2660 |

| APF1520 | Φ1500×2000 | 830×2040 | 700 | 320-550 | 315-400 | 45 | 3959×3564×3330 |

| With two counterattack chambers, large processing capacity, large feeding particle size and good particle shape. *Note: Technical parameters are subject to change without prior notice. The output is calculated based on medium-hard materials and a bulk density of 1.6t/m3. The power is calculated based on medium-hard materials and an altitude below 1000 meters. The opening adjustment of the crushing chamber is divided into mechanical and hydraulic. |

|||||||

Specifications of 2-in-1 Mobile Impact Crushers for sale

| 2-in-1 Tire Type Mobile Impact Crusher Specification | ||

|---|---|---|

| Model | APY2-1213F-S3 | APY-1315F-S3 |

| Machine power(kw) | 223 | 285.5 |

| Processing capacity(tph) | 80-280 | 100-350 |

| Main Crusher | ||

| Model | APF-1213H | APF-1315H |

| Motor power(kw) | 160 | 250 |

| Maximum feed(mm) | 300 | 300 |

| Belt Conveyor | ||

| Screen conveyor | B1000 | B1200 |

| Discharge height (mm) | >3100 | >3100 |

| Vibrating screen | ||

| Model | APY-1860-S3 | APY-2160-S3 |

| Motor power(kw) | 2*7.5 | 2*11 |

| Speed(r/min) | 1000 | 1000 |

Specifications of 3-in-1 Mobile Impact Crushers for sale

| 3 in 1 Tire Type Mobile Impact Crusher Specification | ||||

|---|---|---|---|---|

| Model | APY3-1110F-S3 | APY3-1210F-S3 | APY3-1213F-S3 | APY3-1315F-S3 |

| Machine power (kw) | 199.9 | 202.4 | 270.4 | 346.5 |

| Machine processing capacity (t/h) | 50-110 | 70-120 | 80-150 | 130-260 |

| Vibrating feeder | ||||

| Model | APG-0930Z | APG-0930Z | APG-9538Z | APG-1145Z |

| Feed trough width (mm) | 800 | 800 | 900 | 1100 |

| Length(mm) | 3000 | 3000 | 4000 | 4800 |

| Main Crusher | ||||

| Model | APF-1010H | APF-1210H | APF-1214H | APF-1315H |

| Motor power (kw) | 132 | 132 | 200 | 250 |

| Feeding depth (mm) | 500 | 600 | 600 | 700 |

| Feeding width (mm) | 400 | 400 | 400 | 400 |

| Maximum feed (mm) | 420 | 420 | 500 | 600 |

| Discharge port (mm) | >30 | >30 | >30 | >30 |

| Vibrating screen | ||||

| Model | APS-1548Y3 | APS-1548Y3 | APS-1860Y3 | APS-2160Y3 |

| Motor power (kw) | 2*5.5 | 2*5.5 | 2*7.5 | 2*11 |

| Belt Conveyor | ||||

| main conveyor | B800*11m | B800*11m | B1000*11m | B1200*12m |

| Power (kw) | 11 | 11 | 11 | 15 |

| Feeding conveyor B800 | B800*16m | B800*16m | B1000*16m | B1200*17m |

| Power (kw) | 15 | 15 | 15 | 15 |

| Screen conveyor B800 | B800*7.5m | B800*7.5m | B1000*7.5m | B1200*7.5m |

| Power (kw) | 5.5 | 5.5 | 7.5 | 11 |

| Silo volume (m³) | 3 | 3 | 4 | 5 |

| Conveyor discharge height (m) | >4.5 | >4.5 | >4.5 | >4.5 |

| Generator power (kw) | 300 | 300 | 400 | 500 |

Specifications of Crawler Type Impact Crushers for sale

| Crawler Type Mobile Impact Crusher Specification | |||

|---|---|---|---|

| Model | APYL2-1110F-S | APYL2-1213F-S | APYL2-1315F-S |

| Power(kw) | 217.2 | 265.8 | 347.2 |

| Capacity(t/h) | 80-150 | 110-220 | 150-300 |

| Feeding hopper | |||

| Volume(m³) | 3 | 4 | 5 |

| Vibrating feeder | |||

| Model | APG-0930Z | APG-9538Z | APG-1145Z |

| Width of material trough(mm) | 800 | 950 | 1100 |

| Length(mm) | 3000 | 3800 | 4500 |

| Power(kw) | 2*2.2 | 2*3.7 | 2*7.5 |

| Impact Crusher | |||

| Model | APF-1110H | APF-1213H | APF-1315H |

| Power(kw) | 132-160 | 200-250 | 280-315 |

| Max.Feeding Size(mm) | 450 | 500 | 600 |

| Return screen | |||

| Mesh Spec.(mm) | 1500*3600 | 1500*4200 | 1800*4200 |

| Power(kw) | 6.12 | 6.12 | 6.12 |

| Main belt conveyor | |||

| Belt Width(mm) | B1000 | B1000 | B1200 |

| Reducer Power(kw) | 7.5 | 7.5 | 11 |

| Belt Speed(m/s) | 1.6 | 1.6 | 1.6 |

| Side belt conveyor(Optional) | |||

| Belt Width(mm) | B650 | B650 | B650 |

| Reducer Power(kw) | 4 | 4 | 4 |

| Discharge Height(mm) | 2100 | 2100 | 2200 |

| Belt Speed(m/s) | 1.6 | 1.6 | 1.6 |

| Lower belt conveyor | |||

| Belt Width(mm) | B1000 | B1000 | B1200 |

| Reducer Power(kw) | 7.5 | 7.5 | 11 |

| Discharge Height(mm) | 3200 | 3200 | 3200 |

| Belt Speed(m/s) | 1.6 | 1.6 | 1.6 |

| Belt transfer conveyor | |||

| Belt Width(mm) | B650 | B650 | B650 |

| Reducer Power(kw) | 4 | 4 | 4 |

| Belt Speed(m/s) | 1.6 | 1.6 | 1.6 |

| Return belt conveyor | |||

| Belt Width(mm) | B500 | B500 | B500 |

| Reducer Power(kw) | 5.5 | 5.5 | 5.5 |

| Belt Speed(m/s) | 1.6 | 1.6 | 1.6 |

| Crawler Width(mm) | 500 | 500 | 500 |

| Magnetic Separator | |||

| Model | RCYD-10 | RCYD-10 | RCYD-12 |

| Power(Kw) | 3 | 3 | 4 |

| Hanging Height(mm) | 300 | 300 | 350 |

| magnetic field intensity(mT) | 70 | 70 | 70 |

| Weight(Kg) | 2120 | 2120 | 2250 |

| Dimension: L×D×H(mm) | 2660x1550x920 | 2660x1550x920 | 2880x1720x1010 |

What is the Impact Crusher Prices in Indonesia?

Looking for an impact crusher in Indonesia? Impact crusher prices usually range from $27,000 to $72,300, but the real value lies in performance, durability, and low maintenance. Whether you want a budget-friendly option or a high-performance machine, there’s a perfect fit for your project. Contact us now for the best harga impact crusher!

With a clear understanding of impact crusher prices and options, you can choose the right machine for your budget and project needs. Next, see real Indonesian projects where our crushers deliver stable performance, high-quality aggregates, and proven reliability—helping you visualize how our crushing equipment works on the ground.

Impact Crushers at Work: Real Results from Indonesia and Worldwide

From Jakarta city roads to large highway and bridge projects worldwide, our horizontal shaft impactor crushers prove their efficiency, reliability, and quality every day. Contractors in Indonesia rely on them to crush faster, save costs, and produce top-quality aggregates. Let’s dive into these global projects and see our crushers in action.

100T Stationary Impact Crusher for Crushing Cobblestones

Location: in Malaysia

Capacity: 100TPH

Crushed Materials: Cobblestone

Impact Crusher Applications: Road paving

Customer Review: “We installed a 100T primary impact crusher in Malaysia to crush cobblestones for road paving. The crusher machine runs smoothly, produces high-quality aggregates, and helped us complete the road on time. Very satisfied with its performance!”

100-120T/H Crushing Production Line for Crushing Limestone

Location: Zanzibar, Tanzania

Capacity: 100–120T/H

Crushed Materials: Limestone

Application: Supplying aggregate for own concrete batching plant

Configuration: Stationary vibrating feeder + Jaw crusher + Impact crusher + Vibrating screen

Customer Review: “We installed a 100–120T/H limestone crushing plant in Zanzibar to supply aggregate for our concrete batching plant. The line runs smoothly, produces high-quality, well-graded limestone, and helps us save costs by reducing the need to buy external aggregate. ”

150T Mobile Impact Crusher Plant for Crushing Granite

Location: Bogotá, Colombia

Capacity: 150T/H

Crushed Materials: Granite / Demolition waste

Application: Metro Line 1 construction, producing aggregates for sub-base and concrete

Configuration: Vibration Feeder + Impact crusher + Vibrating screen

Customer Review: “We used the 150T mobile large impact crusher plant for Bogotá Metro Line 1. It efficiently processed demolition waste and granite into well-shaped, well-graded aggregates suitable for metro construction. The plant kept our project on schedule. Very reliable and productive!”

After seeing these real cases, you can clearly feel the efficiency and reliability of horizontal impact crushers in Indonesian projects. Next, let’s explore why investing in an impact crusher in Indonesia can be a key factor for your project’s success.

Why Investing in an Impact Crusher in Indonesia Is a Smart Choice?

With Indonesia’s rapid infrastructure development and urbanization, the demand for aggregates continues to rise. Whether for roads, bridges, ports, or residential projects, aggregates are an essential building material. Investing in a high-efficiency, durable impact crusher can ensure a steady supply, reduce costs, and increase profitability. Here’s an in-depth look at why investing in a compact impact crusher in Indonesia makes sense.

Infrastructure Growth – Exploding Aggregate Demand

- Government investment rising steadily: Infrastructure spending in 2025-2030 is expected to exceed $20 billion (Bappenas), driving aggregate demand.

- Road construction boosts volume: Around 2,500 km of new roads are built annually, requiring 1,000–1,500 tons of aggregates per km.

- Local production saves transport costs: Producing aggregates on-site reduces import or long-distance delivery costs, ensuring project timelines.

Rapid Urbanization – High Aggregate Demand for Housing & Commercial Projects

- Population growth fuels construction: Cities like Jakarta, Surabaya, and Bandung need over 3 million tons of aggregates annually.

- Urban renewal projects increase demand: Renovation and infrastructure upgrades require high-quality aggregates.

- On-site production prevents delays: Mobile impact crusher machines provide continuous supply, avoiding material shortages.

Cost Advantage – Fast ROI, High Investment Return

- Purchase cost savings 30%-50%: Self-produced aggregates can save $8–$15 per ton.

- Daily output 100–150 tons enables quick payback: Monthly savings of $15,000–$20,000, recouping investment in 2–3 years.

- Predictable long-term profits: In-house production reduces price fluctuation risks, increasing gross margin by 15%-20%.

Policies & Environmental Benefits – Green Construction Adds Value

- Waste recycling encouraged: On-site concrete waste processing reduces landfill and transport costs.

- Strict environmental standards: Dust, energy consumption, and noise limits require efficient aggregate crusher machine.

- Green construction boosts competitiveness: Mobile impact crushers reduce environmental impact, meeting local government standards.

Abundant Local Mining Resources: A Solid Foundation for Investment

- Large Limestone Reserves: Regions such as Sulawesi, Kalimantan, and Java have over 5 billion tons of limestone reserves, providing long-term supply security for aggregate production.

- Diverse Aggregate Sources: Sandstone, basalt, and recycled concrete are readily available for roads, bridges, and construction, maximizing reversible impact crusher utilization.

- Government Support: Local value-added processing is encouraged with tax incentives and regional policies that reduce investment risks for modern crushing equipment.

Versatile Impact Crusher Applications – Adaptable to Various Conditions

- Suitable for multiple projects: Roads, bridges, ports, residential, and urban renewal projects.

- Handles various materials: Limestone, granite, concrete waste, and more.

- Flexible mobility reduces idle time: Tire or crawler-type secondary impact crushers move quickly to adapt to complex terrains.

Market Competitiveness – Own Aggregate Production Increases Profit

- Independent aggregate supply: Reduces reliance on third-party suppliers and ensures stable material availability.

- High-quality aggregates build trust: Meets high-standard project requirements and improves client satisfaction.

- Boosts profit margin and market share: In-house production lowers costs, increases gross margin, and captures more market opportunities.

Given these benefits, it’s clear why impact crushers for sale are trusted in Indonesia. To help you make the most of them, we provide customized impact crusher services across the country.

Trusted Impact Crusher Support for Indonesian Contractors

Choosing the right impact crusher is not just about buying a machine—it’s about securing reliable support that keeps your projects running smoothly. In Indonesia, where contractors face tight deadlines, scattered job sites, and rising material costs, having a trusted partner makes all the difference. We, as one of leading impact crusher manufacturers, provide local presence, fast service, and long-term reliability tailored to Indonesian construction needs.

Direct Factory Supply – No Middlemen

Direct Factory Supply – No Middlemen

By purchasing directly from our factories, you can enjoy cost savings and higher value.

- Lower Costs: No middlemen involved, reducing unnecessary markups.

- Transparent Pricing: Clear and fair offers tailored to your budget.

- Best Value: High-quality machines at competitive prices.

Local Offices and Warehouses – Fast Access

Local Offices and Warehouses – Fast Access

We understand the importance of quick delivery and parts supply in Indonesia.

- Local Presence: Branch offices and warehouses across Indonesia.

- Quick Delivery: Faster impact crusher spare parts distribution.

- Less Downtime: Ready stock means shorter waiting times for replacements.

Experienced Engineers and On-Site Support

Experienced Engineers and On-Site Support

We provide more than just machines—we deliver reliable technical support.

- Professional Installation: Ensuring your impact crusher is set up properly.

- Regular Maintenance: Prevent issues and extend machine lifespan.

- On-Site Assistance: Local engineers available for urgent support.

12-Month Warranty for Peace of Mind

12-Month Warranty for Peace of Mind

We protect your investment with a solid 1-year warranty on all impact crushers.

- Assured Reliability: Coverage against unexpected failures.

- Lower Risks: Reduce your operational interruptions.

- Confidence Guaranteed: Secure long-term production stability.

Certified Quality – International Standards

Certified Quality – International Standards

Our impact crushers are built to meet strict global standards.

- CE Certified: Complies with European safety and performance standards.

- ISO9001 Certified: Ensures consistent quality and efficiency.

- Durable Design: Long-lasting machines that support heavy-duty projects.

Customized Solutions and Ongoing Service

Customized Solutions and Ongoing Service

Every project is unique, and we adapt to your needs.

- Tailored Designs: Accept OEM and customized requests.

- Quick Repairs: Local technicians available for fast troubleshooting.

- Reliable Spare Parts: Stable supply to keep your crusher running.

Ready to find the right crusher in Indonesia? If you are looking for a high-quality large or small impact crusher for sale with trusted local support, we are here to help. Contact us today for free consultation, competitive prices, and reliable after-sales service. We will work with you to choose suitable machines for your long-term success.

How Does An Impact Crusher Work

People often ask how an impact crusher works, and the answer lies in its use of impact energy to efficiently crush rocks, stones, and other aggregates into smaller sizes. Let’s delve into the impact crusher Youtube video together! Here’s an impact crusher diagram and impact crusher video showing the impact crusher working principle:

The impact crusher rotor inside the crusher spins at high speed, generating significant kinetic energy that will be used to crush incoming materials.

Rocks, gravel, or other aggregates are fed into the impact hammer crusher through the feed opening, ready to be processed.

As the material hits the rapidly rotating rotor and the breaker plates, large chunks are broken down into smaller pieces.

The partially crushed materials are then thrown against impact bars or hammers for further crushing, ensuring a more uniform particle size.

Materials continue to bounce between the rotor and impact plates, undergoing multiple impacts until they reach the desired size.

Finally, the fully crushed material exits the double rotor impact crusher through the bottom, ready for use in construction, road paving, or concrete production.

Knowing how an impact crusher works and the impact crusher design helps you get the best results, but even the strongest machines can face problems. Next, let’s explore common impact crusher failures and solutions to keep your operation smooth and productive.

Common Impact Crusher Failures and Solutions – Optimized for Indonesia

In Indonesia, construction sites are often scattered, with tropical weather and dusty conditions. Impact crushers may face unique challenges, from high humidity affecting bearings to uneven construction debris entering the crusher. Recognizing these issues and knowing solutions helps local contractors maintain high efficiency and reduce downtime.

Sudden Increase in Vibration

- Local Scenario: Uneven plate hammer replacement on wet limestone or granite can cause imbalance.

- Solution: Carefully reinstall plate hammers, check rotor balance, and ensure proper tightening to stabilize operation.

- Benefit: Reduces unexpected shutdowns and prolongs rotor lifespan.

Excessive Discharge Size

- Local Scenario: Worn liners from abrasive materials like river stone or volcanic rock increase the gap, producing oversized aggregates.

- Solution: Adjust the gap between front and rear impact frames or replace worn liners and plate hammers.

- Benefit: Maintains consistent particle size, meeting road construction and concrete quality standards.

Unusual Knocking or Rattling Sounds

- Local Scenario: Non-crushable debris like metal fragments from demolition projects can enter the crusher, or loose liners can cause noise.

- Solution: Stop the single rotor impact crusher, remove debris, check liner fasteners, and adjust hammer-liner clearance.

- Benefit: Prevents internal damage and keeps production smooth.

Bearing Overheating

- Local Scenario: Tropical climate and dusty environment may cause lubrication issues or contamination, leading to bearing overheating.

- Solution: Check grease levels, clean bearings, replace grease if needed, or replace damaged bearings.

- Benefit: Ensures continuous operation, avoids costly downtime, and extends bearing life.

After understanding the common impact crusher issues and their solutions on construction sites, the next step is learning how to properly maintain your machine. Effective maintenance not only extends the crusher’s lifespan but also ensures stable and efficient operation, keeping your crushing projects running smoothly across all types of Indonesian work sites.

How to Maintain an Impact Crusher on Indonesian Construction Sites?

In Indonesia, construction sites often face high humidity, tropical heat, and scattered locations. Proper impact crusher maintenance is essential to ensure smooth operation, avoid costly downtime, and extend equipment life. Here’s a practical guide tailored for Indonesian conditions:

Impact Crusher Regular Inspections

- Check vibrations: Ensure the impactor machine runs smoothly. Sudden vibration is a warning—stop immediately to inspect rotor and hammers.

- Monitor bearing temperatures: Normal operation is under 35°C; absolute maximum is 70°C. Overheating requires immediate stop and troubleshooting.

- Inspect hammers: Plate hammers wear faster under local materials like limestone and granite. Reverse or replace worn hammers promptly.

- Rotor balance: After replacing hammers, perform a static rotor balance test; imbalance should not exceed 0.25 kg·m.

Rotor and Frame Checks

- Frame liners: Replace worn liners immediately to prevent housing damage.

- Bolt tightening: Check all bolts before starting—loose bolts are a common issue on Indonesian sites due to vibration and transport.

Hydraulic Shell Opening and Closing

- Opening: Use the hydraulic system to open the rear shell for maintenance or replacing liners and plates. Always release all bolts first.

- Closing: After work, detach the support plate, clean sealing surfaces, and close slowly with the hydraulic system to ensure proper sealing and avoid dust leakage.

Lubrication and General Maintenance

- Friction surfaces: Keep all contact points well-lubricated to prevent wear, especially in humid Indonesian conditions.

- Grease selection: Use climate-appropriate grease, generally 2# lithium.

- Bearing care: Lubricate every 8 hours and replace grease every 3 months. Clean bearings thoroughly before refilling with about 50% of the housing volume.

By following these key steps, you can significantly improve the efficiency and longevity of your impactor machine, reducing downtime and costly repairs.

Impact Crusher vs Cone Crusher vs Jaw Crusher – How to Choose

Choosing the right crusher is critical for the success of construction, road, and mining projects in Indonesia. The right equipment ensures efficiency, consistent quality, and lower operating costs. The table below compares impact crushers, cone crushers, and jaw crushers based on features, materials, advantages, and typical Indonesian applications:

| Feature | Impact Crusher | Cone Crusher | Jaw Crusher |

|---|---|---|---|

| Applicable Materials | Limestone, granite, concrete waste, soft to medium hardness ores | Granite, basalt, andesite, medium-hard ores | Limestone, cobblestone, andesite, high-hardness materials |

| Particle Shape & Product Quality | Cubic shape, ideal for sand-making and high-quality road aggregates | Uniform, cubic content slightly lower than impact crusher | Elongated particles, suitable for primary or coarse crushing |

| Equipment Features | Strong secondary crushing and shaping, suitable for reprocessing materials | High crushing ratio, ideal for hard rock continuous crushing | Simple structure, stable operation, low maintenance cost |

| Suitable Applications | Indonesian urban road construction, concrete recycling, sand & gravel production | Indonesian quarries, river stone processing, hard rock crushing including andesite | Indonesian large stone primary crushing, aggregate plant coarse crushing including andesite |

| Advantages | Cubic aggregates, energy-efficient, flexible with mobile units | High efficiency and output, wear-resistant, suitable for long-term mining | Durable, easy to maintain, flexible investment |

| Considerations | Wear parts need regular maintenance, best for medium-soft materials | Higher investment cost, fixed-site installation recommended | Product shape less cubic, suitable for coarse crushing and subsequent shaping |

Indonesia Application Tips

- In city road projects or when recycling concrete waste, an impactor crusher gives better particle shape and improves construction quality.

- When processing harder stones such as andesite or granite, a cone crusher delivers higher efficiency and longer service life, making it ideal for quarries and long-term use.

- For very large raw stones or the first stage in aggregate plants, a jaw crusher handles coarse crushing, and it can be combined with an impactor crusher for shaping or sand production.

Impact Crusher FAQs for Indonesian Contractors

Working with an impact crusher in Indonesia can raise many questions. From components to wear parts, knowing the answers can save time and costs on your projects. This FAQ guide gives clear, practical tips for contractors across Indonesia, helping you run your impactor crusher efficiently and keep your site productive.

What is an Impact Crusher, and where is it used in Indonesia?

What are the Main Components of an Impact Crusher, and What Do They Do?

- Rotor – The rotating core with hammers or plate hammers that crush materials at high speed.

- Plate Hammer – Fixed on the rotor, it strikes materials to start the crushing.

- Impact Plate – Rebounds materials back to the rotor for further crushing.

- Crushing Chamber – Holds plates and lining for repeated crushing.

- Lining Plate –Protects the chamber and guides material flow.

- Inlet – Entry point for raw materials into the rotor and crushing chamber.

- Discharge Port – Where crushed materials exit.

- Adjusting Device – Sets the gap between plate and rotor to control output size.

- Motor – Powers the rotor for continuous crushing.

What Are the Main Wear Parts of an Impact Crusher?

- Plate Hammer – Hits the materials directly at high speed. Because of the constant impact and friction, it wears faster than most other parts.

- Impact Plate – Located inside the crushing chamber, it repeatedly strikes materials and also experiences heavy wear over time.

- Liner – Protects the inner walls of the crusher from damage. After long-term use, it needs replacement to maintain efficiency.

- Sieve Bars – Used to screen crushed materials, they are also prone to wear and should be checked regularly.

What are the differences and similarities between an Impact Crusher and a Hammer Crusher?

Similarities

- Materials are crushed using impact force in both crushers.

- They can produce relatively uniform aggregates suitable for construction.

- Ideal for processing medium to low hardness stones.

Differences

- Working Principle: Impact crushers strike materials multiple times using a rotor and impact plates; hammer crushers use rotating hammers to hit materials directly.

- Material Hardness: Impact crushers handle medium to low hardness stones; hammer crushers are better for softer materials.

- Product Shape: Impact crushers produce cubic, well-graded aggregates; hammer crushers may produce finer or irregular shapes.

- Maintenance: These crushers have more durable wear parts; hammer crushers need hammer replacement more often.

- Crushing Ratio: Best impact crushers can reach up to 20:1; hammer crushers usually 10–15:1.

Get Your Impact Crusher Today!

Ready to improve efficiency and reduce costs on your site? Our impact crusher China can handle limestone, granite, and construction waste with ease. Contact us now for a quote and local support in Indonesia—fast delivery, reliable service, and smooth operation guaranteed!