Concrete Batching Plant Price Starts from $10,000

25–240 m³/h Capacity – Fit for All Project Scales

Fast Delivery Across Indonesia, Ready to Work On-Site

Concrete batching plant price in Indonesia ranges from $10,000 to $400,000, with capacities from 25 m³/h to 240 m³/h. If you’re building roads in Jakarta or houses in Kalimantan, knowing the concrete plant price range helps you choose the right batch plant and stay on budget. This guide makes it easy to understand the cost and find the best fit for your needs.

Looking for a reliable concrete batching plant at a great price? Aimix has you covered! We offer high-quality jual batching plants that are durable, precise, and easy to use. Check out our latest daftar harga batching plant below to find the perfect option for your construction needs.

| Concrete Batching Plant Price Ranges in Indonesia | |||

|---|---|---|---|

| Plant Size | Capacity (m³/h) | Price Range (USD) | Typical Use Case |

| Small Scale | 25–35 m³/h | $10,000 – $35,000 | Rural housing, village roads |

| Medium Scale | 50–75 m³/h | $35,000 – $70,000 | Urban construction, precast |

| Large Scale | 90–240 m³/h | $70,000 – $400,000 | RMC supply, expressways, big sites |

| 💡 Prices include standard configuration, excluding cement silo, shipping, and local installation fees. | |||

All in all, you’ve seen our harga mesin batching plant and have some understanding of what we offer. Now, let’s dive into the technical specifications of different types of concrete batching plants. This will help you better understand concrete batching plant prices and make an informed choice. Let’s see the harga dan spesifikasi batching plant in the following.

Explore Concrete Batching Plant Price & Types in Indonesia

To help you choose the right concrete batching plant dijual in Indonesia, we’ve listed key models with their concrete batch plant price ranges, capacities, and main features. Whether for small sites or large projects, batch plants cover a wide range of construction needs and budgets. Check the details below to find the best batching plant for your project.

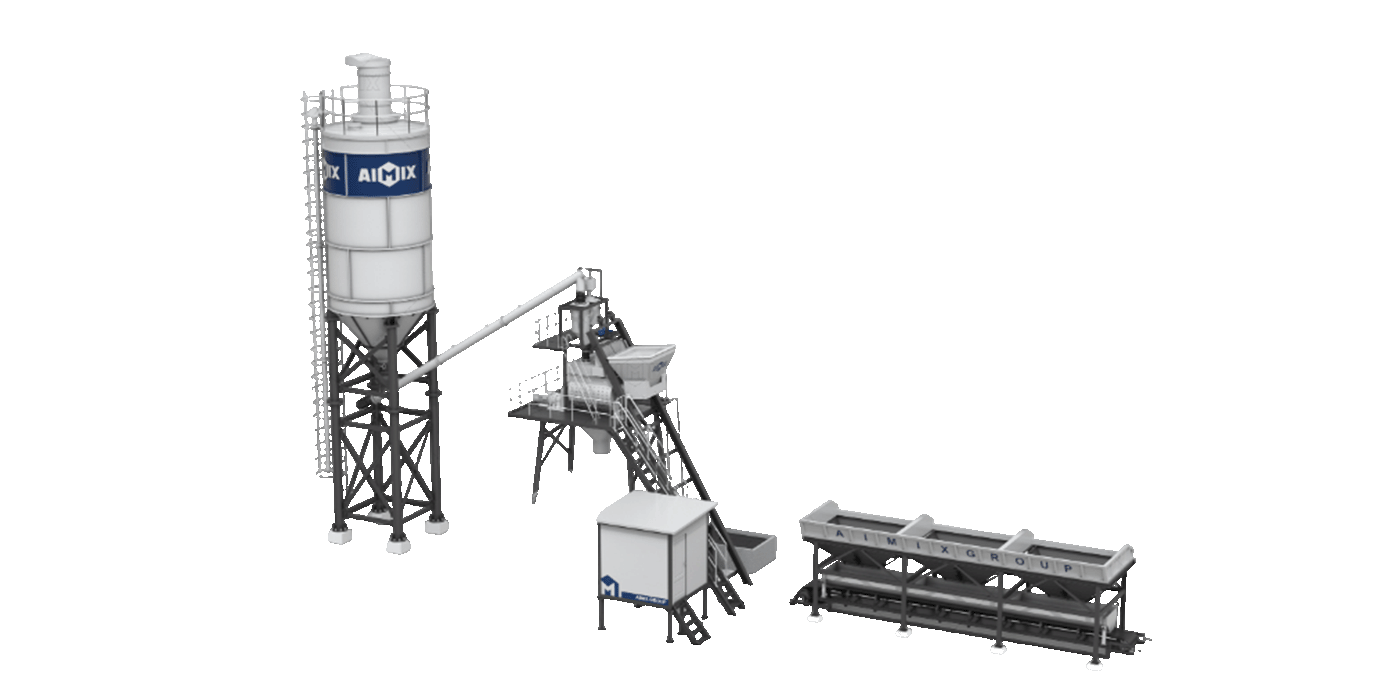

AJ Hopper Type Stationary Batching Plant

- Price Range: $10,000 – $100,000

- Concrete Output: 25-75m³/h

- Feeding Method: Lifting hopper

- Models: AJ25, AJ35, AJ50, AJ75

- Suitable Projects: Small to medium projects, housing, municipal works

- Target Users: Contractors with limited space and budget

- Key Features: Integrated Control System: Reduces startup time by 30%, lowers operator error by 50%; Accurate Weighing: Material waste reduced by 10%; Remote & Auto Calibration supports material shortage alerts;

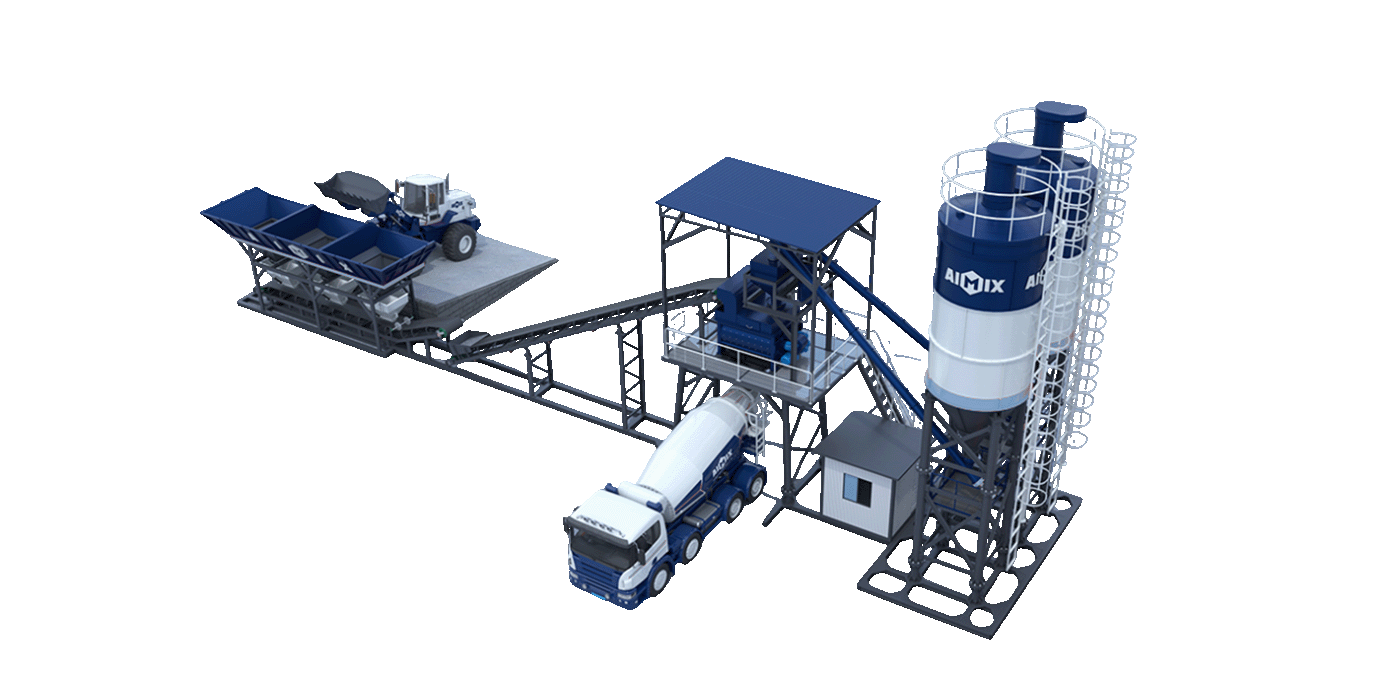

AJ Belt Type Stationary Batching Plant

- Price Range: $50,000 – $400,000

- Concrete Output: 60-240m³/h

- Feeding Method: Belt conveyor

- Models: AJ60, AJ75, AJ90, AJ120, AJ180, AJ240

- Suitable Projects: Commercial concrete production, highways, bridges

- Target Users: Ready-mix concrete suppliers, construction companies

- Key Features: Full automation with PLC + manual control, IOT smart monitoring system (lower maintenance cost by 25%), Integrated foundation; setup in 7–10 days, and Dual-shaft or planetary mixer options.

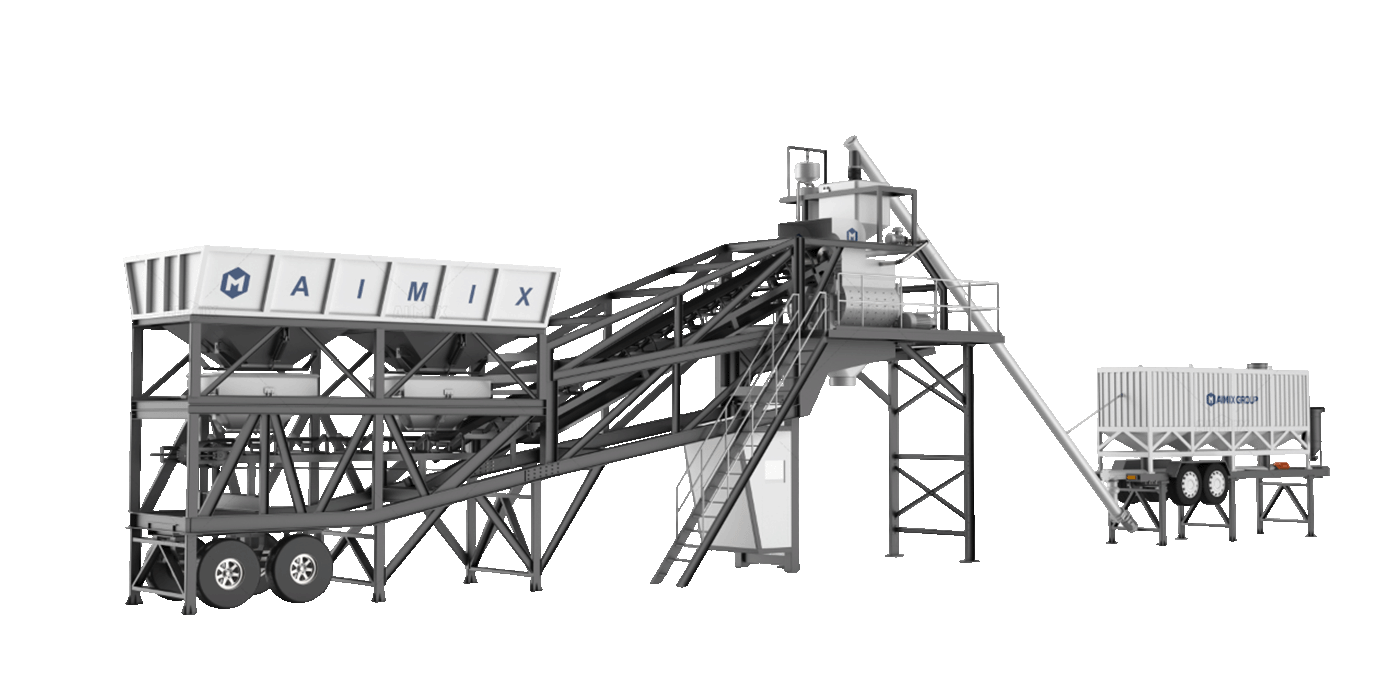

AJY Mobile Batching Plant for Sale

- Price Range: $30,000 – $120,000

- Concrete Output: 25-60m³/h

- Mixer: Twin shaft mixer, Planetary

- Models: AJY25, AJY35, AJY60, AJY75, AJY90, AJY120

- Suitable Projects: Medium multiple project sites, ready-mix on the move

- Target Users: Contractors with frequent site changes, rental businesses

- Key Features: Movable wheels, medium flexibility, Semi-foundation setup, fast relocation (1–2 days), Fully automatic control system, and Ideal for medium-to-high concrete grade projects.

AJSY Compact Mobile Mini Batch Plant

- Price Range: $30,000 – $130,000

- Concrete Output: 25-50m³/h

- Mixer: Twin shaft mixer

- Models: AJSY25, AJSY35, AJSY50

- Suitable Projects: Urban or remote village housing, fast delivery sites

- Target Users: Small tight-space contractors, precast-product makers

- Key Features: Foundation-free, installation in 0.5 day, Designed for fast transfer, Intelligent wireless control (1-man operation), Compact footprint, low land requirement and Precision weighing (≤±1%), stable quality.

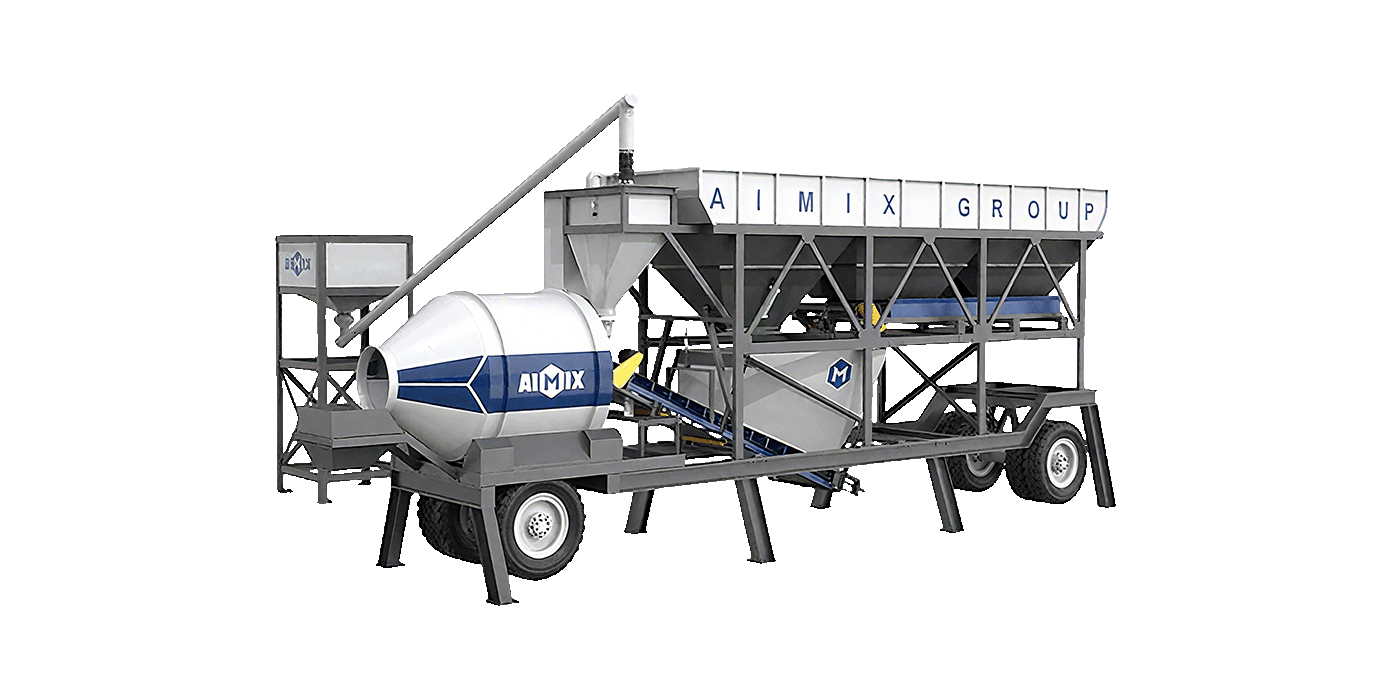

AJZY Drum Type Mobile Batching Plant

- Price Range: $30,000 – $90,000

- Concrete Output: 15-60m³/h

- Mixing Period: 90-120 s

- Models: AJZY20, AJZY40, AJZY60

- Suitable Projects: Rural roads, houses, low-grade concrete (≤C30)

- Target Users: Rural contractors, housing projects, budget-limited projects

- Key Features: No foundation, ultra-compact design, Easy relocation, setup in hours, Drum mixer for plastic or fluid concrete, Extremely cost-effective, low maintenance, Perfect for small-volume, frequently moving jobs.

AJM Foundation-Free Concrete Batching Plant

- Price Range: $30,000 – $100,000

- Concrete Output: 25–75 m³/h

- Mixer: Twin shaft mixer

- Models: AJM-25, AJM-35, AJM-50, AJM-75

- Suitable Projects: Temporary sites, leased land projects, fast-track builds

- Target Users: Contractors with frequent site changes or tight deadlines

- Key Features: No Foundation saving on civil work and installation time, Ready to run in 0.5–1 day, Full Automation, Consistent mixing quality with minimal manpower, Ideal for time-sensitive and short-term projects.

Picking the right concrete batching plant isn’t just about the price you see. Different types come with different features and fit different project sizes and budgets here in Indonesia. So, why does the price vary so much? Let’s dive into the main reasons behind the costs — this way, you’ll know exactly how to choose the best batch plant for your needs and budget.

What Are The Factors Affecting The Price Of A Concrete Batching Plant?

Buying a concrete batching plant is a big investment, especially in Indonesia’s diverse construction environment. To make the best choice without wasting money, consider these key factors that truly affect the concrete mixer plant price and fit your real project needs:

Project Size & Concrete Volume Needs

- Small-scale projects like village housing in Java or road repairs in rural Sumatra need hopper-type small concrete batching plants (25–75 m³/h) that are affordable and easy to use.

- Large infrastructure projects like Jakarta’s toll roads or commercial developments require high-capacity belt-type plants (60–240 m³/h) to keep up with heavy demands.

- Picking the right capacity avoids wasted money on oversized equipment or delays from underpowered concrete mixing plants for sale.

Mobility & Site Transfer Frequency

- Indonesia’s geography means many projects move between islands like Bali, Kalimantan, and Sulawesi.

- Fixed batching plants are cheaper but costly and slow to relocate.

- Mobile concete plant for sale (AJY, AJSY) come with a higher upfront concrete batch plant price but save days or weeks on transport and setup — a real benefit for contractors working across islands or remote areas.

- Think about how often your work sites change before choosing a batch plant type.

Foundation Requirements & Local Ground Conditions

- Soft, marshy soils in places like Papua or uneven volcanic land in Sulawesi can make foundation work expensive and time-consuming.

- Foundation-free models (AJM series) or mobile drum mixers (AJZY) avoid costly foundation work, speeding up project starts.

- Ignoring local soil conditions can cause equipment damage or costly downtime.

Automation Level & Technology Features

- Advanced automation like IoT monitoring and predictive maintenance helps reduce labor costs and avoid breakdowns—valuable for long-term projects or government contracts in Indonesia.

- For smaller projects or regions with less technical labor, semi-automatic or manual controls balance cost and ease of use.

- Choose technology levels based on your team’s skills and project length.

After-Sales Support & Spare Parts Availability

- Quick access to spare parts and local technicians is crucial to keep projects on track.

- Choosing concrete batching plant suppliers with service centers in major cities like Jakarta, Surabaya, or Medan can prevent costly downtime.

- Investing a bit more for strong local support saves money and stress in the long run.

Climate & Material Adaptation

- Indonesia’s tropical climate brings heavy rains, high humidity, and coastal salty air, which wear down equipment faster.

- Plants with corrosion-resistant parts, weatherproof coatings, or mixers designed for local aggregates perform better and last longer.

- Spending more upfront on climate-adapted equipment avoids frequent repairs and extends machine life.

Now that you know what affects the price of concrete batching plant in Indonesia, the next step is learning how to use this knowledge to find the best deal. Understanding these factors will help you avoid overpaying, choose ready mix plant that fits your exact needs, and ensure smooth construction without costly delays. Keep reading to discover smart tips and local insights.

How to Get A Good Concrete Batching Plant Price in Indonesia?

Buying a concrete batching plant for sale is a major investment for any construction business in Indonesia. To get the best batching plant harga without sacrificing quality and service, consider the following key points tailored for the Indonesian market:

Understand Your Project Needs Clearly

Compare Local and Imported Options

Check for Included Services and Warranties

Negotiate Based on Volume and Payment Terms

Consider Total Cost of Ownership (TCO)

Verify Compliance with Indonesian Standards and Regulations

Read Reviews and Request References

Getting a good concrete batching plant price is just one step, but understanding the full biaya pembuatan batching plant is equally important. Next, let’s look at how much it actually costs to set up a concrete batching plant in Indonesia, so you can budget wisely and avoid surprises.

How Much Does It Cost to Set Up A Concrete Batching Plant?

How much does a concrete batch plant cost? What are the cost inputs for concrete batching plant? Setting up a concrete batching plant in Indonesia involves various costs influenced by several factors. Here are the key components and estimated biaya pembuatan batching plant:

Land and Site Preparation: $5,000 – $30,000 (Varies by region—urban areas like Jakarta are more expensive, while rural locations in Java may cost less.)

Equipment Purchase: $10,000 – $400,000 (Concrete mix plant prices depend on plant type and capacity; local suppliers often offer competitive rates.)

Installation & Commissioning: $3,000 – $15,000 (Includes foundation work, wiring, and testing—mobile plants usually install faster.)

Utilities Setup (Electricity, Water): $2,000 – $8,000 (Power supply can be less reliable in remote areas, so plan accordingly.)

Labor & Training: $1,500 – $5,000 (Hiring and training local operators is essential for smooth operation.)

Permits & Licenses: $500 – $3,000 (Regulations vary by province; ensure all local permits are in place.)

Spare Parts & Initial Materials: $2,000 – $7,000 (Stock essential parts to reduce downtime and maintenance delays.)

Total Initial Setup Concrete Plant Cost: Approximately $24,000 to $470,000+ depending on plant size, location, and project needs.

Knowing the total setup cost helps you plan your investment wisely. Once you have a clear budget in mind, the next step is finding reliable suppliers that offer quality plants at competitive harga batching plant beton. Next, let’s see where to find quality concrete batching plants for sale in Indonesia.

Where Can I Find Concrete Batch Plants for Sale?

If you are looking for high-quality concrete batch plant for sale, consider the following main purchasing channels. Especially for Indonesian customers, AIMIX offers professional solutions and excellent after-sales service, making it a trustworthy choice.

Online Marketplaces

Benefits: These platforms allow you to search for specific products, compare harga batching plant beton, and read reviews from different sellers.

Tips: Make sure to check the seller’s ratings, customer feedback, and return policies before making a purchase.

Manufacturer Websites

Detailed Information: These websites often provide comprehensive product information, including specifications, features, and customer testimonials.

Exclusive Offers: Concrete plant manufacturers’ websites may offer exclusive deals, promotions, and warranty information that you won’t find elsewhere.

Social Media and Forums

Peer Reviews: These communities can help you get recommendations, read user reviews, and seek advice from experienced professionals in the field.

Networking: Engage with industry experts and peers to learn about the latest trends, technologies, and best practices.

Exhibitions and Trade Shows

Live Demonstrations: You can see the equipment in action, which helps in understanding its performance and capabilities.

Expert Advice: Discuss your specific needs and requirements with industry experts, and get immediate answers to your questions.

Finding the right supplier is key to getting a quality concrete batching plant for sale that fits your needs and budget. To help you choose confidently, let’s look at real concrete batching plant projects in Indonesia and see how different solutions have worked in practice.

Powerful Batching Plant Projects Across Indonesia

AIMIX concrete batching plants have been successfully used in over 100 construction projects across Indonesia, including roads, bridges, housing, and factories. Our equipment supports local contractors with fast setup, stable output, and low maintenance. These real projects show how AIMIX fits different project needs across the country.

AJY60 Mobile Batching Plant

![]() Delivery time: July 2024

Delivery time: July 2024

![]() Location: in Besica, Indonesia

Location: in Besica, Indonesia

Customer Review:Mr. Sam, Mr. Vincent, and their team provided outstanding service in setting up our local batching plant. They worked tirelessly throughout the day to ensure optimal performance. We are thankful for their dedication and will continue to work with AIMIX to maintain the mobile concrete batching plant’s efficiency.

AJ-60 Stationary Batching Plants

![]() Delivery time: February 2024

Delivery time: February 2024

![]() Location: in Tarakan, Indonesia

Location: in Tarakan, Indonesia

Customer Review:The 60 m³/h stationary batching plant from AIMIX in Indonesia has exceeded our expectations. Its flawless installation and operational efficiency have been instrumental in helping us meet our project timelines. We are impressed with the consistent quality of concrete it produces, which has significantly enhanced our project outcomes.

AJ-60 Stationary Concrete Batch Plants

![]() Delivery time: March 2023

Delivery time: March 2023

![]() Location: in Kalimantan

Location: in Kalimantan

Customer Review:For our road and bridge projects in Kalimantan, we invested in a 60 m³/h concrete batching plant from AIMIX. The installation was executed flawlessly, and the plant is consistently producing high-quality concrete. We are very pleased with the level of service provided by AIMIX and are enthusiastic about the prospect of further collaborations.

AJ-60 Stationary Concrete Batch Plants

![]() Delivery time: September 2024

Delivery time: September 2024

![]() Location: in South Sumatra

Location: in South Sumatra

Customer Review:We purchased the AJ-60 belt type stationary concrete batching plant for our projects in South Sumatra, Indonesia. The setup was smooth, and the plant is working exceptionally well, providing consistent high-quality concrete. AIMIX’s customer service has been excellent throughout the process. We are very happy with this purchase and highly recommend it.

Seeing real concrete batching plant projects in Indonesia helps you understand how different solutions fit various needs. If you’re curious about pricing details and common concerns, the next section answers frequently asked questions to guide your buying decision.

Concrete Batching Plant Price FAQs

When considering the purchase of a concrete batching plant, it’s natural to have questions about the pricing and what it entails. Here are some frequently asked questions to help you better understand the costs and factors involved in pricing a concrete batching plant harga.

Is Financing Available for Purchasing A Concrete Batching Plant in Indonesia?

What is the Lead Time for Delivery and Installation in Indonesia?

Are There Warranties or Guarantees Included with the Purchase?

How Do I Choose the Right Supplier for My Concrete Batching Plant?

How Much Does A 35m3/h Concrete Batching Plant Cost?

What is the cost of concrete batching plant? Aimix supplies AJ-35 and AJY-35 for sale. Both of them can produce 35m3 concrete per hour. Hence, you should first confirm which type of small concrete batching plant you need if you want to make clear the 35m3/h rmc plant price. Get the batching plant harga.

- For AJ-35, it belongs to stationary-type concrete plants for sale. AJ-35 is worth of 20,000 – 50,000USD.

- Regard AJY-35, it is a mobile concrete batch mix plant. AJY-35 is worth of 40,000 – 80,000USD.

As the above mentioned, although AJ-35 and AJY-35 have the same concrete productivities, their configuration, and parts are different. For example, the AJ-35 stationary mini batch mix plant uses a skip hopper to load sand and gravel materials. But AJY-35 mini mobile concrete batching plant for sale uses a belt conveyor for carrying the stone materials. Go on checking their specific technical details below.

AIMIX Concrete Batching Plant Manufacturer in Indonesia

AIMIX is one of the leading concrete batching plant manufacturers, dedicated to delivering high-quality construction solutions across Indonesia. With extensive experience in the local market, we offer a range of concrete batching plants designed to meet diverse project needs—from small-scale urban builds to large infrastructure developments.

Wide Product Variety

Our portfolio includes plants with capacities ranging from 25 m³/h to 240 m³/h, perfectly suited for various Indonesian projects, whether it’s residential, commercial, or government infrastructure.

Innovative Technology

AIMIX batching plants feature smart automation and IoT monitoring, improving production efficiency by up to 20% and reducing downtime by 40%, ensuring stable and consistent concrete quality.

Quality Service

We provide comprehensive pre-sales consultation and prompt after-sales support, including local spare parts availability and professional training, to help Indonesian contractors minimize project risks.

Market Focus

Understanding Indonesia’s unique geography and regulations, we tailor our solutions to fit regional requirements and operational challenges, especially in key areas like Java, Sumatra, and Bali.

Choose AIMIX Indonesia as your trusted partner in Indonesia for efficient and dependable concrete production solutions. Contact us now to get the latest harga concrete batching plant and customized offers. We are ready to support your construction success with the best products and services.

How We Can Support Your Projects in Indonesia

AIMIX is your trusted partner for jual concrete batching plants in Indonesia. No matter what your project needs are, we are dedicated to providing high-quality equipment and services to ensure your construction projects run smoothly. Our specific services include:

Consultation and Planning

We offer professional advice to help you choose the most suitable concrete batching plant for your project. Our team will work with you to optimize every detail.

Installation and Training

Our experienced technicians ensure an efficient installation process and provide comprehensive operational training for your team to ensure safe equipment operation.

Maintenance and Support

We offer regular maintenance services to keep your equipment in optimal condition. Our support team is always ready to quickly resolve any issues.

Spare Parts Supply

We maintain a comprehensive stock of essential spare parts to minimize downtime and ensure your project continues without interruptions.

Choose AIMIX for reliable and comprehensive services to support the success of your construction projects. Contact us to learn more about concrete batching plant price from us.

Ready to Buy Your Batching Plant with Proper Budget?

Looking to buy concrete batching plant for sale? Don’t wait! Reach out to us today to discuss your ideal model or size of AIMIX concrete batch plants. We are here to assist you in finding the best solution and offer competitive harga batching plant. Send us your inquiry now, and let’s make your project a success together! And get the harga batching plant baru di Indonesia.