Efficient, Smart, and Reliable One-Stop Mixing Solution

Trusted by Global Fortune 500 Partners

Precise Feeding System for Improved Efficiency

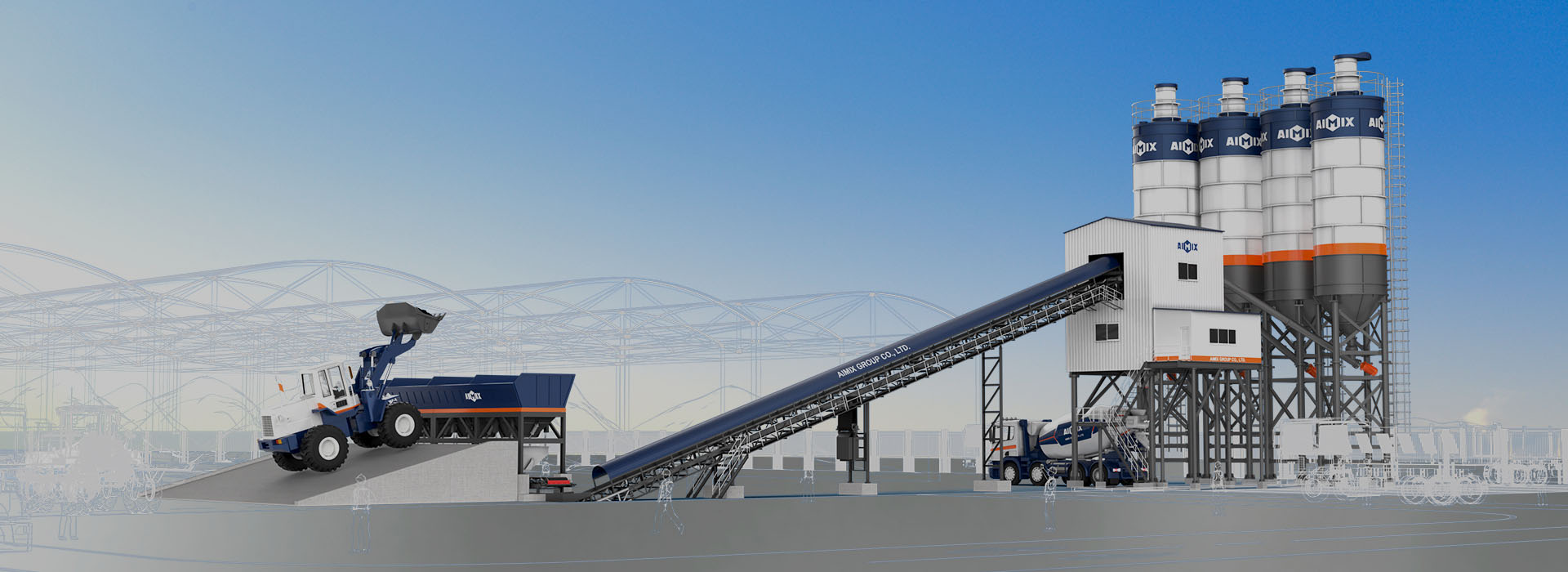

Apa itu batching plant? What is a batch plant? A concrete batching plant adalah a specialized facility used to produce high-quality concrete, where various raw materials—such as cement, aggregates, water, and additives—are precisely mixed to form concrete. The meaning of batching plant is to ensure the accurate and efficient concrete production by automating the entire mixing process, crucial for construction projects. We’ll show something you need to know about batching plant.

Now, let’s take a closer look at the key components that make up a concrete batching plant and understand how each part contributes to the overall operation.

What are the Components of a Concrete Batching Plant?

A concrete mixing plant adalah a complex system made up of several key components that work together to produce high-quality concrete. These include systems for batching, conveying, weighing, mixing, and controlling. Let’s explore the main components that make up a batching plant:

Aggregate Batching System

Conveying System – Belt Conveyor

Weighing System

Storage System – Cement Silo & Screw Conveyor

Mixing System – Concrete Mixer

Control Room

What is the Concrete Batching Plant Working Principle?

To produce high-quality concrete efficiently, it’s crucial to understand the working principle of a concrete batching plant. This equipment ensures accurate measurement and mixing of raw materials, producing concrete that meets the required specifications. Let’s explore the key steps about cara kerja batching plant.

Material Measurement

After measuring the aggregates, the system transfers them onto a continuously running belt conveyor. The conveyor sends the measured aggregates to the top-floor storage bin.

Powder and Additive Conveying

The screw conveyors then move the powder materials, such as cement and fly ash, to their respective weighing bins. At the same time, water and additives are pumped into their designated bins for measurement.

Sequenced Material Delivery

Once all materials are measured, the system follows a predefined sequence. It opens the doors of the aggregate storage bin to release the aggregates into the mixer. After a brief delay, the system adds the measured water, additives, cement, and fly ash to the mixer in order.

Mixing and Discharge

Finally, the mixer combines the materials into concrete. Once the mixing process completes, the system discharges the concrete through the main outlet into the mixing truck, finishing one batch cycle.

Types of Concrete Batching Plant – Mobility and Mixing Process

While all concrete batching plants serve the same core purpose—precisely mixing aggregates, cement, and water—their designs vary to meet specific project needs. Understanding these variations helps maximize efficiency. Concrete batching plants are classified by mobility (stationary or mobile) and mixing process (dry mix or wet mix).

By Mobility: Stationary vs. Mobile Batching Plants

Concrete batching plants are classified by mobility—stationary or mobile. Stationary batching plant meaning is that it’s fixed in one location, perfect for long-term, high-output projects. Mobile batch plants, on the other hand, can be relocated easily, making them ideal for projects that require flexibility. Understanding these options helps you choose the right plant based on your project’s needs.

Stationary Concrete Batching Plant

Hot Models: AJ60AJ90AJ120AJ180

Capacity: 25-400 m³/h

Mixer: JS Series Twin Shaft Mixer, Planetary Mixer

Installation Period: 7-10 days

Aggregate Feeder: Skip Hopper/Belt Conveyor

Foundation Requirements: Concrete Foundation

Required Land Area: High

Control System: Fully Automatic Control

Applications: Precast & Ready-Mix Production, Construction, Large-Scale Concrete Supply

Advanced Features: One-touch operation, IoT remote monitoring, optimized feeding system, flexible design, and durable mixers from BHS and SICOMA for reduced downtime, waste, and maintenance costs.

Mobile Concrete Batching Plant

Models: AJY Belt TypeAJSY Compact AJZY Drum Type

Capacity: 15-120m³/h

Main Mixer: Twin shaft mixer, Planetary Mixer, Drum Mixer

Installation Period: 3-7 days AJY Series, 0.5 days AJSY Series, 1-2 days AJZY Series

Foundation: Free foundation(AJY Series Simple Foundation)

Required Land Area: Low(AJY Series High)

Control System: Manual/Fully automatic control

Application: Small to medium projects, residential, commercial, road construction, tight spaces, high land cost areas.

Advantages: AJY Series (Easy relocation, fast setup, high mobility), AJSY Series(Compact, quick setup, low land use), AJZY Series(Strong mobility, low cost, simple operation)

By Mixing Process: Dry Mix vs. Wet Mix

Concrete batching plants also differ by mixing process: dry mix and wet mix. In dry mix plants, ingredients are mixed dry and combined with water at the site. What is batching plant wet mix? Wet mix plants combine all ingredients, including water, before delivery. Knowing the difference helps you select the right plant for your project’s concrete needs.

Wet Mix Concrete Batching Plant

Models: AJ SeriesAJY SeriesAJZY SeriesAJSY Series

Capacity: 25 m³/h to 400 m³/h

Mobility: Stationary/Mobile Type

Production Process: Dry materials and water mixed in the plant, transported by mixer trucks.

Quality Control: Better control over uniformity and consistency for higher quality concrete.

Equipment Configuration: Includes batching, conveying systems, mixer, and water supply system.

Applications: High-quality concrete for high-rise buildings, large infrastructure projects, and projects requiring uniformity.

Dry Mix Concrete Batching Plant

Mobility: AJ SeriesStationaryMobile

Capacity: 25 m³/h to 400 m³/h

Production Process: Dry materials mixed inside the plant, water and liquids added during transport or on-site mixing.

Quality Control: Relying on mixer truck for uniformity, quality may vary.

Equipment Configuration: Simple, with batching and conveying systems for dry materials.

Applications: Ideal for projects with less stringent concrete quality requirements or sites with mixing equipment and skilled personnel.

What You Need to Know About Batching Plant Technical Parameters

When you’re exploring what is concrete batching plant, it’s important to understand how its technical parameters affect your project’s success. The specific configuration—such as production capacity, mixing process, and quality control—can vary depending on the type of ready mix concrete plant. By understanding these key technical features, you can learn which type is right for you.

AJ Series Stationary Type

| Model | Bucket type | Belt type | ||||||

|---|---|---|---|---|---|---|---|---|

| AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 | |

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 60 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Kind of Aggregate | 3/4/2002 | 3/4/2002 | 3/4/2002 | 3/4/2002 | 3/4/2002 | 3/4/2002 | 3/4/2002 | 3/4/2002 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Power Supply | 380V/220V/415/440V, 50/60HZ, 3Phase | |||||||

AJ Series Eco-Friendly Type

| Model | AJ-180 | AJ-240 | AJ-270 | AJ-300 | |

|---|---|---|---|---|---|

| Theoretical productivity(m3/h) | 180 | 240 | 270 | 300 | |

| Mixer | JS3000 | JS4000 | JS4500 | JS5000 | |

| Power of mixing machine(kw) | 2×55kw | 2×75kw | 2×75kw | 2×90kw | |

| Aggregate maximum particle | 80 | 80 | 80 | 80 | |

| Feeding capacity(L) | 4500 | 6000 | 6750 | 7500 | |

| Discharge capacity(L) | 3000 | 4000 | 4500 | 5000 | |

| Aggregate bin capacity(m3)(optional) | steel storage | 4×25 | 4×25 | 4×30 | 4×30 |

| barn | 4×6 | 4×6 | 4×6 | 4×6 | |

| Aggregate batching capacity(L) | 4800 | 6400 | 7200 | 7200 | |

| Belt conveying capacity(t/h) | 900 | 1200 | 1200 | 1400 | |

| Screw conveying capacity(t/h) | 80 | 110 | 170 | 170 | |

| Discharge height(m) | 4.2 | 4.2 | 4.2 | 4.2 | |

| Installed capacity(kw) | 220 | 280 | 300 | 340 | |

| Weighing range | stone | (900-3600)±2% | (900-4800)±2% | (900-5000)±2% | (900-6000)±2% |

| sand | (900-3600)±2% | (900-4800)±2% | (900-5000)±2% | (900-6000)±2% | |

| cement | (300-1800)±1% | (400-2400)±1% | (400-2700)±1% | (400-3000)±1% | |

| fly ash | (200-600)±1% | (200-800)±1% | (200-1200)±1% | (200-1400)±1% | |

| water | (200-800)±1% | (200-1100)±1% | (200-1300)±1% | (300-1500)±1% | |

| additive | (15-70)±1% | (20-100)±1% | (20-110)±1% | (20-120)±1% | |

AJY Series Mobile Type

| Parameters/Model | AJY-25 | AJY-35 | AJY-50 | AJY-60 | AJY-75 | AJY-90 | AJY-120 |

|---|---|---|---|---|---|---|---|

| Mixer | JS500 | JS750 | JS-1000 | JS1000 | JS1500 | JS1500 | JS2000 |

| Mixer discharge capacity | 0.5m³ | 0.75m³ | 1m³ | 1m³ | 1.5m³ | 1.5m³ | 2m³ |

| Productivity (m³/h) | 25m³/h | 35m³/h | 50m³/h | 60m³/h | 75m³/h | 90m³/h | 120m³/h |

| Aggregate Material Quantity (m3) | 2×6m3 | 2×8m3 | 2×8m3 | 2×10m3 | 2×10m3 | 2×12m3 | 2×12m3 |

| Discharging Height (m) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 |

| Weighing Accuracy | Aggregate Weighing Accuracy: ±2% | ||||||

| Powder Material Weighing Accuracy:±1% | |||||||

| Water Weighing Accuracy:±1% | |||||||

| Additive Weighing Accuracy: ±1% | |||||||

| Installation Power (kW) | ≈60.8 | ≈72.3 | ≈92 | ≈92 | ≈102 | ≈120 | ≈160 |

| Traction Type | Semi-trailer | ||||||

| Power Supply | 220V/415V/440V/380V/, 50HZ/60HZ, 3Phase | ||||||

AJSY Series Mobile Compact Type

| Model | AJSY35 |

|---|---|

| Productivity | 35 m³/h |

| Mixer | JS750 |

| Mixer capacity | 0.75 m³ |

| Aggregate bins capacity | 2×3.5 m³ |

| Control | Manual/Fully automatic control (with touch screen) |

| Cement weighing | 500kg |

| Water weighting | Time Relay |

| Additive weighing | Time Relay |

| Main frame | Channel steel |

| Chassis Size | 7.8×2.6×2.95m |

AJZY Series Mobile Drum Type

| Model | AJZY 40 with 2 bins | AJZY-60 with 3 bins |

|---|---|---|

| Capacity | 30-40m3/h | 50-60m3/h |

| Mixer | JZM1000 (1m3) | JZM1500 (1.5m3) |

| Mixing Period | 40s | 40s |

| Discharging Height | 1.3m | 1.3m |

| Batcher | 2 bins x 5m3 | 3 bins x 5m3 |

| Feeding Height | 3.2m | 3.2m |

| Cement Weighing System | 500kg | 500kg |

| Water Weighing System | 300kg | 400kg |

| Horizontal Cement Silo | 50ton | 50ton |

| Screw Conveyor | 219x8mx11kW | 219x8mx11kW |

| Chassis Size | 8410x2000x780mm | 11100x2000x780mm |

| Tyres | 1000mm | 1000mm |

| Control System | Semi Auto with Control Panel | Semi Auto with Control Panel |

| Container Needed | 1*40HQ | 1*40HQ |

Where Are Concrete Batching Plants Used?

Concrete batching plants play a crucial role in construction by automating and optimizing concrete production. They serve key industries—from large infrastructure projects to residential builds—ensuring consistent quality, efficiency, and cost savings. Here are the most important applications.

Commercial & Residential Construction

Infrastructure & Civil Engineering

Industrial & Warehouse Construction

Precast Concrete Manufacturing

Ready-Mix Concrete Supply

Specialized Applications

Commercial & Residential Construction

High-rise buildings, housing projects, and urban developments require consistent, high-quality concrete for foundations, slabs, and structural elements.

Precast concrete production (e.g., walls, beams, columns) benefits from automated batching for uniformity.

Infrastructure & Civil Engineering Projects

Roads, highways, and bridges need durable, high-strength concrete for long-lasting performance.

Airport runways, tunnels, and dams rely on large-scale batching plants for continuous supply.

Industrial & Warehouse Construction

Factories, warehouses, and logistics centers often use pre-mixed concrete for flooring and structural support.

Precast Concrete Manufacturing

Modular construction (precast panels, pipes, blocks) requires precise batching for standardized production.

Ready-Mix Concrete Supply for Small to Medium Contractors

Local construction projects (e.g., driveways, sidewalks, small buildings) depend on RMC (Ready-Mix Concrete) plants for quick delivery.

Specialized Applications

Decorative & stamped concrete (for aesthetic projects) needs precise mix designs.

Self-compacting concrete (SCC) and fiber-reinforced concrete for advanced engineering needs.

When to Use a Concrete Batching Plant: A Beginner’s Practical Guide

what is a batching plant used for? If you’re new to construction, you couldn’t just know what is a concrete plant, and you also should learn “When should I use one? How do I know if my project needs the large or mini batch plant?” Don’t worry—this guide breaks it down in simple, actionable terms so you can make the best decision for your project.

High-Volume Projects (Ready-Mix Can’t Keep Up)

- Best for: Highways, bridges, dams, large-scale buildings

- If your project requires 500+ cubic meters of concrete per day, relying on ready-mix trucks may cause delays.

- A batching plant ensures uninterrupted supply, preventing costly downtime.

Remote or Hard-to-Reach Sites (Transport Costs Are Too High)

- Best for: Rural areas, mountainous regions, overseas projects

- When the construction site is over 30 km (18 miles) from the nearest ready-mix plant, transportation costs skyrocket, and concrete quality may degrade.

- A mobile batching plant set up on-site ensures fresh concrete without long-haul delivery expenses.

Strict Quality Control Requirements (Custom Mixes Needed)

- Best for: High-strength concrete, waterproof mixes, specialized structures

- Ready-mix suppliers often use standard formulas—if you need custom mixes (e.g., fiber-reinforced, fast-setting, or low-permeability concrete), a batching plant lets you fine-tune ratios.

- Essential for projects following ACI, ASTM, or EN standards.

Long-Term Projects (Cost Efficiency Over Time)

- Best for: Projects lasting 6+ months (e.g., housing complexes, industrial parks)

- While ready-mix is convenient for short jobs, long-term projects save 20-40% by producing concrete on-site.

- Bulk purchasing of raw materials (cement, sand, aggregates) reduces costs significantly.

Eco-Friendly Construction (Lower Carbon Footprint)

- Best for: Green building projects, government-regulated sites

- Fewer truck deliveries mean less CO₂ emissions and dust pollution.

- On-site plants can recycle wastewater and unused concrete, reducing waste.

🚀 Need personalized advice? DM or comment with your project details—we’ll help you choose the most cost-effective solution!

What is the Future of Batching Plants: Efficiency & Sustainability

As a construction professional, staying ahead of industry trends isn’t just beneficial—it’s critical to your project’s efficiency, cost control, and sustainability. Here’s a breakdown of the latest advancements and shifts in concrete batching plant technology, backed by data and real-world applicability:

Smart Automation & IoT Integration

- Real-time monitoring of material usage, moisture levels, and mix consistency, reducing waste by up to 15% (World Economic Forum, 2023).

- Predictive maintenance alerts, cutting downtime by 20-30% (McKinsey, 2024).

- Remote operation capabilities, allowing managers to oversee multiple sites from a single dashboard.

- Why this matters to you: Fewer delays, lower labor costs, and precise quality control—directly impacting your project’s bottom line.

Green Concrete & Carbon-Neutral Operations

- Alternative materials: Fly ash, slag, and recycled aggregates are now standard in eco-friendly mixes.

- Electric & hybrid plants: Volumetric batching plants with electric motors reduce fuel dependency (e.g., Liebherr’s E-Moticon system).

- Carbon capture tech: Pioneering plants like Heidelberg Materials’ CCUS-enabled facilities aim for net-zero concrete by 2030.

- Your advantage: Compliance with tightening regulations (e.g., EU Carbon Border Tax) and appeal to eco-conscious clients.

Modular & Mobile Plants for Agile Projects

- Quick deployment (48–72 hours vs. weeks for traditional plants).

- Scalability—add mixers or silos as project needs evolve.

- Cost savings for small-to-mid-sized contractors (up to 30% lower TCO).

- Ideal for: Remote sites, urban infill projects, or contractors needing flexibility.

Advanced Material Science: Self-Healing & High-Performance Concrete

- Nano-admixture dosing systems for precision-strength customization.

- Automated testing labs for instant quality assurance.

- Your ROI: Longer-lasting structures with reduced maintenance costs.

Supply Chain Resilience Through Localized Production

- AI-driven logistics optimizing local aggregate sourcing.

- Micro-plants for just-in-time production (e.g., Cemen Tech’s mobile units).

- Your takeaway: Less reliance on volatile global supply chains = fewer project stoppages.

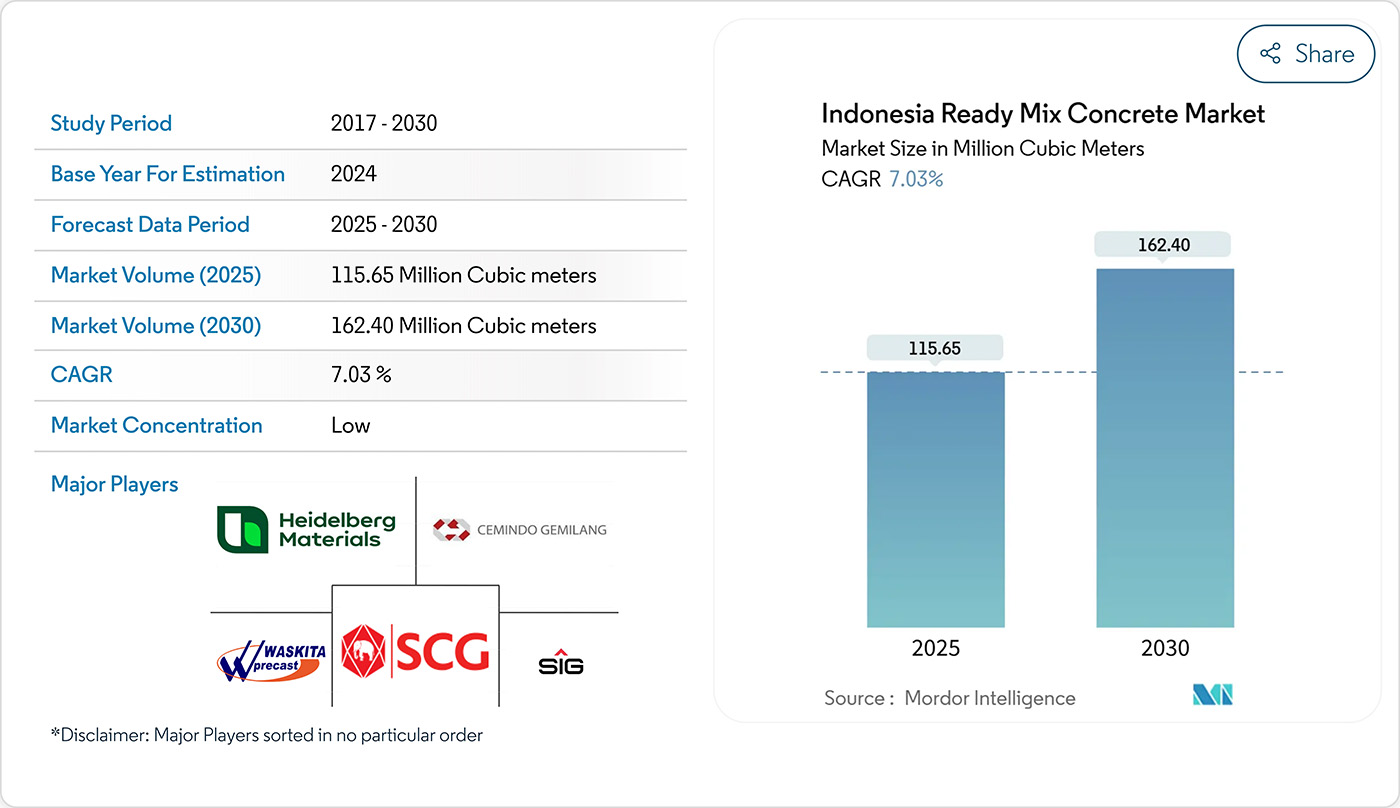

Indonesia Ready Mix Concrete Market Overview – Seize the Opportunity

Indonesia’s ready-mix concrete market is expected to grow from 115.65 million cubic meters in 2025 to 162.40 million cubic meters by 2030, with a CAGR of 7.03%. This growth is driven by large infrastructure projects and urbanization, supported by the government’s IDR 392 trillion infrastructure budget in 2023. Sustainability goals, such as building 1 million green homes by 2030, are also shaping the market.

Key Trends of Demand for Ready-mix Concrete

- Commercial Sector: The commercial real estate market is projected to reach USD 1.39 trillion by 2028, boosting demand for concrete in retail and office spaces.

- Residential Sector: Urbanization and government housing initiatives are driving growth, with a focus on cost-effective concrete solutions like transit-mixed concrete.

Market Segments by Different Projects

- Residential: Dominates with 47% market share in 2024, driven by government housing projects and a preference for transit-mixed concrete.

- Commercial: Expected to grow at 9% from 2024-2029, supported by foreign investment in office and retail spaces.

- Infrastructure: Major projects like Patimban Port and Kayan Hydro Power Plant are fueling demand for high-quality concrete.

Product Segmentation

- Transit Mixed Concrete: Accounts for 74% of market share, favored for residential construction.

- Shrink Mixed Concrete: Gaining popularity in infrastructure and commercial projects due to its operational efficiency.

- Central Mixed Concrete: Preferred for large-scale infrastructure requiring high-quality concrete.

The Indonesian ready-mix concrete market is set for strong growth, driven by infrastructure, urbanization, and sustainability initiatives. Companies must focus on innovation and operational efficiency to remain competitive.

Indonesia’s Major Infrastructure Projects Fueling Concrete Demand

Indonesia’s next decade of growth hinges on transformative infrastructure projects that demand vast quantities of ready-mix concrete and advanced batching solutions. From highways and railways to industrial hubs, these large-scale developments—geared toward economic expansion and urbanization—will reshape the nation’s landscape.

New Capital Nusantara (IKN)

- Location: East Kalimantan (Penajam Paser Utara & Kutai Kartanegara)

- Type: National smart city & infrastructure

- Scale: 2,560 km², planned population 1.9 million

- Developer: Indonesian Ministry of Public Works (PUPR) & state-owned firms (e.g., Waskita Karya)

- Progress: Core government zone construction started in 2024; full completion by 2045

- Concrete Demand: 12 million m³ (2024-2029 phase)(IKN)

Jakarta-Surabaya Railway

- Location: Java North Coast (Jakarta to Surabaya)

- Type: Railway upgrade

- Scale: 750 km, speed 160-200 km/h

- Developer: Ministry of Transportation & PT KAI

- Progress: Feasibility study completed; Semarang section tender in 2025

- Concrete Demand: 3.5 million m³

Trans-Sumatra Toll Road

- Location: Sumatra (Bengkulu-Lampung sections)

- Type: Highway network

- Scale: 400 km remaining, $4.8B total investment

- Developer: BPJT & PT Hutama Karya

- Progress: Bengkulu-Lampung construction starts 2025; full operation by 2030

- Concrete Demand: 6 million m³

Balikpapan-Samarinda Toll Road

- Location: East Kalimantan (Balikpapan to Samarinda)

- Type: Toll road

- Scale: 99 km, 8 bridges

- Developer: PT Wijaya Karya (WIKA) & PT PP

- Progress: Land acquisition done in 2024; completion by 2027

- Concrete Demand: 1.8 million m³

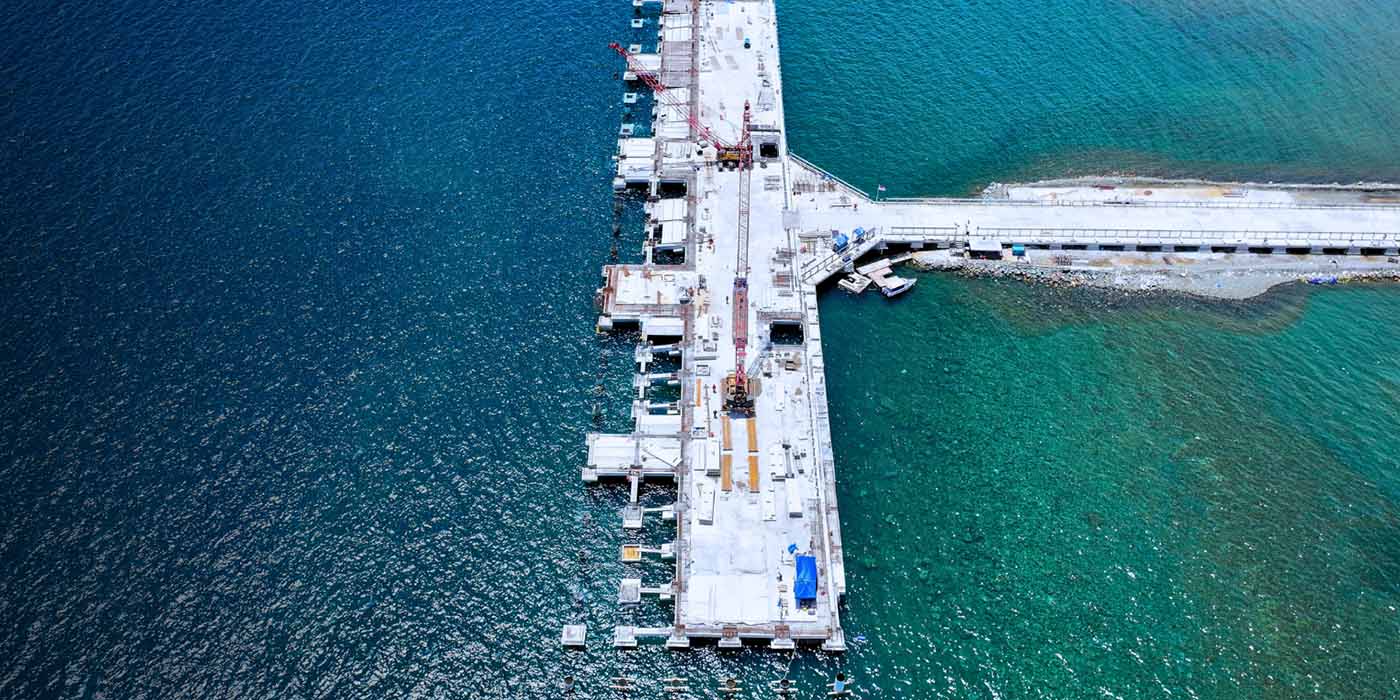

Patimban Port Phase III

- Location: Subang, West Java

- Type: Deep-sea port expansion

- Scale: +7 million TEU capacity

- Developer: Pelindo & JICA

- Progress: Phase III tender in 2024; completion by 2027

- Concrete Demand: 2.5 million m³

West Sulawesi Nickel Park

- Location: Mamuju, West Sulawesi

- Type: Nickel processing & EV supply chain

- Scale: 5,000 ha, 1.2M-ton annual output

- Developer: PT Vale Indonesia & Huayou Cobalt

- Progress: Land preparation in 2024; first line operational by 2028

- Concrete Demand: 0.8 million m³/year

FAQs Helping Know More about Batching Plant

What is batching in concrete?

What is a concrete batcher?

How to decide whether to use ready-mixed concrete or build your own batching plant?

Is the operation complicated? Does it require professional technicians?

What is the function of a batching plant?

What procedure is required to set up a batching plant?

Seize the Opportunity with A Batching Plant

A concrete batching plant is key to ensuring consistent, high-quality concrete for your projects. By understanding batching plant itu apa, you can make an informed choice that meets your specific needs. If you have any questions about pengertian batching plant, our team is here to help guide you through the process with expert advice.